5 Surprisingly Common U Channel Edge Trim Applications

What Is U channel edge trim? First off, a U channel is a tall, skinny, metal formed product. Deeper channels (a little d …

Roll Forming Design Guide for Sheet Metal Components

People not familiar with roll forming usually need some education regarding the machines’ capabilities and limitations – …

6 Ways to Get More Out of Your OEM Metal Roll Forming Process

Does your roll former bring you value beyond simply just doing roll forming? To be competitive, a manufacturer has to of …

Are You Getting Roll Forming Services From An Agile Manufacturer?

What makes a link in your supply chain “agile?” To answer, look at your favorite examples of modern manufacturers and pr …

Can Outsourcing 1 Part to a Metal Roll Forming Company Boost Profits?

U.S. manufacturing has had its share of bad turns over the last 50 years, with entire industries being outsourced to oth …

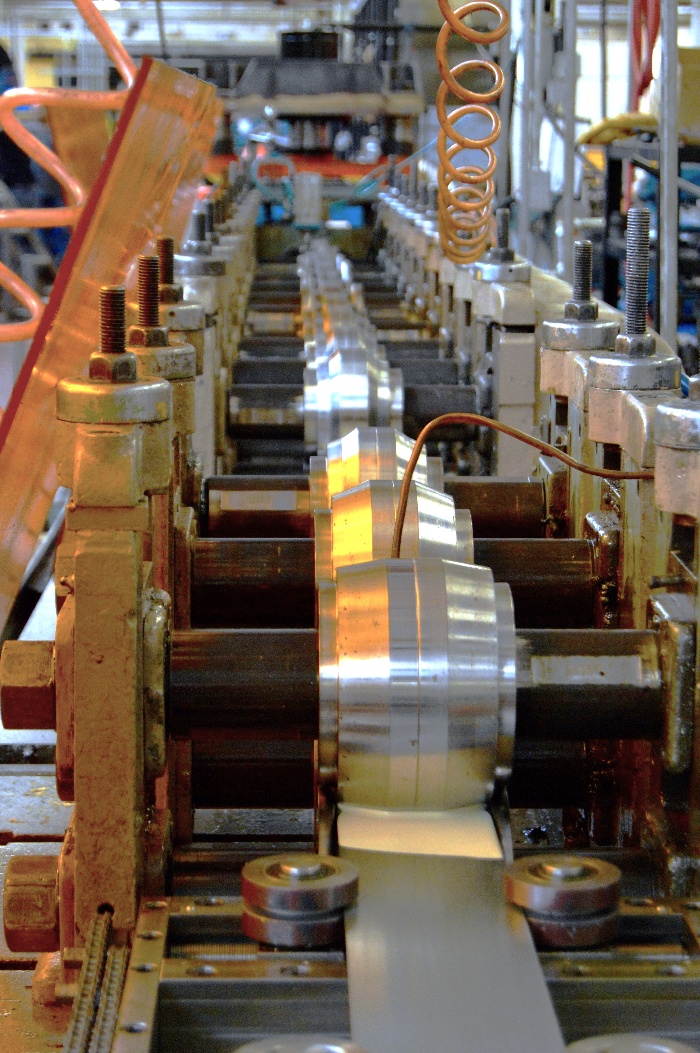

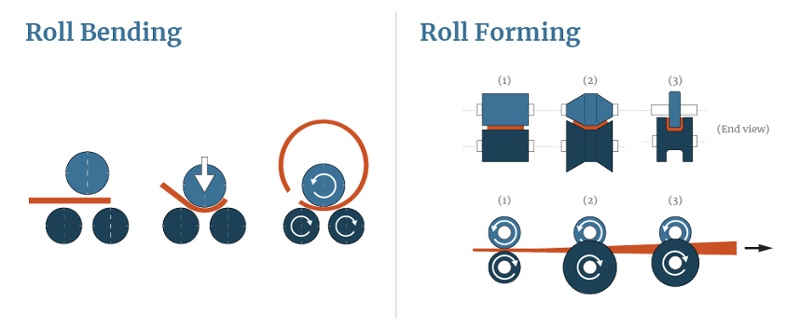

Do You Need a Roll Former or a Roll Bender?

We’re often asked if we can make metal cylinders or “rings.” And while these things are made with a rolling process, tha …

Why Get Custom Roll Forming From a Single Source?

For manufacturers who require a continuous flow of custom roll forming, late shipments and stock outages can negatively …

Reshoring Your Roll Forming To Create a More Efficient Supply Chain

You’ve seen the pictures of shipping barges idling off the coasts of the United States. You may have had delays in shipm …

Beyond Costs: Roll Forming Advantages & Value

You need a metal forming process that will produce a quality product at the right price, meet your inventory needs, and …

Why Your Roll Former Needs Better Manufacturing Shipping Solutions

Customers don't ask for much. All they want is the right product at the right price, delivered on time and free from def …