Cold Roll Forming Vs. Hot Rolled: Which is Right for Your Project?

The Cold, Hot Facts Between Cold Roll Forming and Hot Rolling When selecting roll forming for your projects, durability, …

What Is Metal Roll Forming? | Metal Manufacturing Processes

“What is metal roll forming?” Even design engineers with 20+ years of experience still Google this question. Despite its …

Beyond Steel: Mastering Metal Properties for Your Roll Forming Project

A deep understanding of metal properties is your secret weapon in roll forming. It gives you the confidence to make the …

3 Considerations: Partner With A Roll Former Corporation Vs. In-House

Bringing metal roll forming processes into your plant is a complex investment. It’s more than just buying a machine that …

How Vendor Managed Inventory Benefits Your Bottom Line

Maintaining an inventory of what a client needs for production is a delicate and complicated balance. As inventory ages, …

Why Get Custom Roll Forming From a Single Source?

For manufacturers who require a continuous flow of custom roll forming, late shipments and stock outages can negatively …

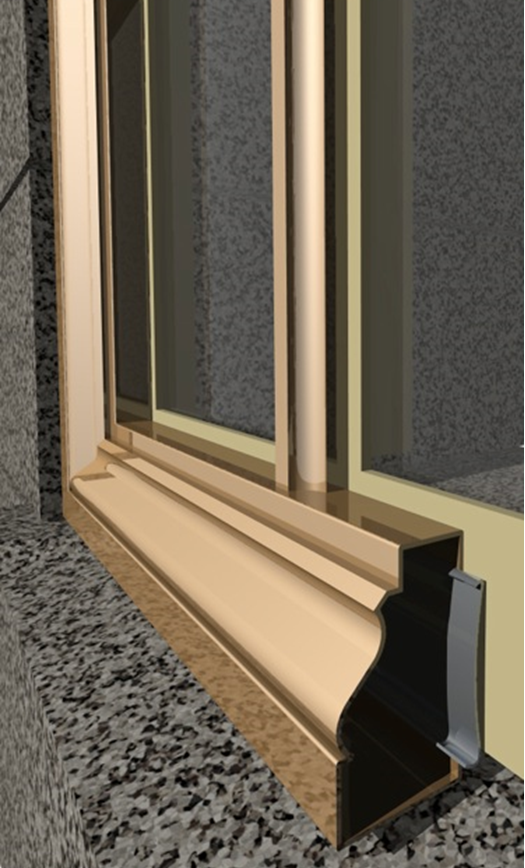

The Secret Trick to Great Steel Windows: Hollow, Roll Formed Parts

Steel windows are great. Steel windows on your terms are even better. These sleek, modern products are now popular in no …

Galvannealed vs Galvanized Steel for Architectural Design

Galvannealed and galvanized steels start out similarly. They are both dipped into a hot zinc bath (approximately 850° F) …

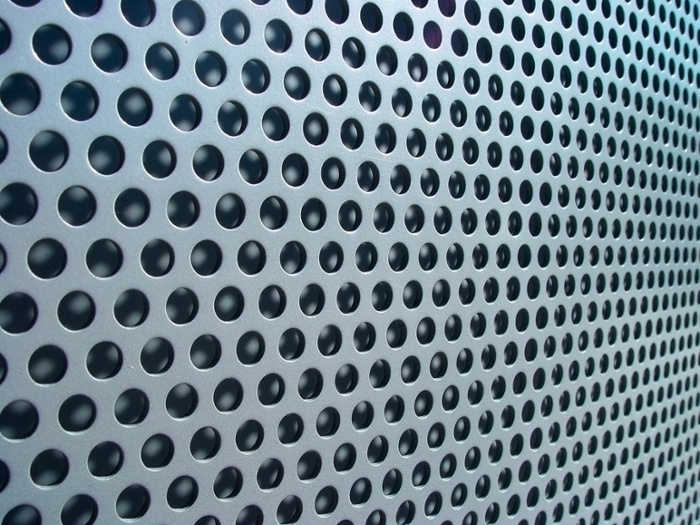

Roll Forming: A Versatile Sheet Metal Punching Partner

Roll formed components often require hole punching -- after all, that’s probably one reason why you chose roll forming t …

Galvanized Steel Vs. Stainless Steel in Architecture & Interior Design

Galvanized steel and stainless steel are big in construction circles -- but what about architecture and interior design? …