3 Considerations: Partner With A Roll Former Corporation Vs. In-House

Bringing metal roll forming processes into your plant is a complex investment. It’s more than just buying a machine that you turn on and off whenever you need it. There are additional costs and risks you won't understand unless you run a full-blown roll forming company.

Bringing metal roll forming processes into your plant is a complex investment. It’s more than just buying a machine that you turn on and off whenever you need it. There are additional costs and risks you won't understand unless you run a full-blown roll forming company.

You may have found a used roll forming machine and thought, “Oh, that seems simple enough.”

You may be considering having a new equipment manufacturer design and install a turnkey custom machine. Maybe you're even looking at portable roll forming equipment.

Or, maybe you're weighing the pros and cons of roll forming in-house vs. outsourcing to an experienced roll former corporation.

All of these options can bring success, but to what degree depends on your company's operations, needs, and goals.

Let’s take a closer look at those influencing factors.

Working In-House vs. With a Roll Former

Why do companies choose to make parts from cold rolled steel in the first place?

Compared to other manufacturing methods like extrusion or casting, metal roll forming systems offer distinct part production advantages:

- Speed

- In-line punching or notching

- Economy of scale

- The ability to produce long shapes that wouldn’t fit in a brake press

- Customization

Seeing these advantages, some companies choose to purchase their own roll form machine and manufacture parts in-house. Others see the value in partnering with a custom roll forming corporation to meet their requirements.

In deciding which path is best for your needs, consider:

- In-House Inventory Control vs. Vendor Deliveries

- Cost of Roll Forming Equipment vs. ROI

- Roll Form Operator Skills vs. Quality Control

1. In-House Inventory Control vs. Vendor Deliveries

Control over inventory and quantities is one reason companies bring roll forming in-house. But how does inventory control stack up against the cost of roll forming operations? Ask yourself these questions:

- Will there be a full-time line operator?

- Will your company be able to balance the cost, output, and other dependent processes of full-time

roll forming?

Roll form manufacturers already have balanced systems to provide full-time roll forming capabilities at a reasonable cost.

They can also manage your inventory for you - whether that means JIT/Kanban management or large volume, make-and-ship orders. Inventory costs are one of those factors that can sneak up on you.

Stock should be minimized to reduce costs while providing a buffer for changes in demand. Inexperienced inventory management can cause costly supply chain disruptions.

Additionally, a company that practices pull system inventory management can operate very similarly to an in-house inventory program. Pull system inventory management allows for point-of-use consumption data, auto-replenishment, and preset minimum carry levels.

2. Cost of Roll Forming Equipment vs. ROI

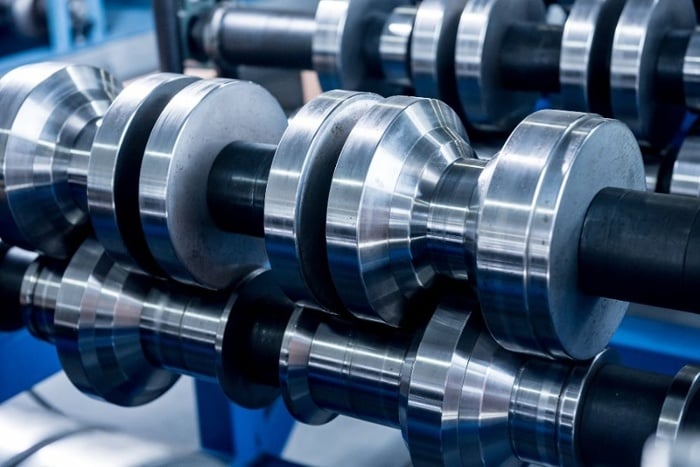

Roll forming equipment is more than just the forming machine itself. Here’s an in-depth overview of a standard roll forming production line. This includes:

- Material handling equipment

- Loading crane

- Uncoiling system

- Pre-punch press (if your part has holes, slots, or tabs)

- Accurate feeder/control system

- Flying die cutoff accelerator with controls

- Appropriately sized cut-off press

The cost of a complete roll forming system can range from $200,000 to $2,000,000 depending on the complexity of your part family. Most in-house systems can only produce one part profile, and a typical line can generate about 1.5 million linear feet per year in a single-shift operation.

So, if you’re planning on purchasing your own roll forming system, you'll most definitely need high volumes to see a decent ROI.

Learn more about the Anatomy of a Roll Forming Line:

3. Roll Form Operator Skills vs. Quality Control

Roll forming training, unlike that of press braking machinery, is quite extensive. Only operators with years of experience in this specific manufacturing process can consistently pump out quality parts. Here are only a few of the considerations for each line:

- Commercial metal thicknesses and physical properties vary considerably

- Runs with various lots of metal require precise adjustments to produce the expected profile

- Adjustments must be made to account for springback of harder metals

- Thicker lots require more space between roll forming tools

- Unequal pressure on roll forming shafts will cause twist and bow

- How to account for part stretching

- How to avoid metal crashing into dies

Can your in-house operators cover all of these bases? You’d better hope so.

On the other hand, an experienced roll forming manufacturer is guaranteed to understand and account for these variables. They may even be ISO certified for delivering high quality goods and services.

Further, a true roll forming supplier knows how to squeeze the most out of the equipment and raw materials – reaping the most efficiency from the process as possible.

Seasoned operators can run multiple profiles and metals on a single line. That means equipment investment costs stay as low as possible.

Equipment adjustment techniques take years to master. Experts are costly to hire full-time for your own operations.

And, if you need service contractors, they very likely will not have schedules that meet your urgent needs. That puts your supply chain and your customers at risk.

How to Streamline Your Roll Forming Costs

Although in-house roll forming is appropriate for some companies, it’s definitely not a cost-effective alternative for everyone. A contractor is almost always better positioned to leverage the many advantages of roll forming to their fullest extent. And perhaps more importantly, it will produce higher ROI and reduce stress for your company.

To recap, here are the costs that go into a comprehensive in-house roll forming system:

- Basic roll forming machine

- Equipment components

- Experienced niche labor

- Maintenance, troubleshooting, and repairs

- Inventory management

- Materials

- Quality control

- Secondary operations

To better understand your unique needs and whether insourcing is right for you, it's important to learn about every factor -- big and small -- that affects roll forming costs.

Why Partner With A Roll Former Corporation

You know you want your metal parts roll formed, but you’re still on the fence about outsourcing vs. in-house roll forming? Check out our Manufacturer’s Guide to Partnering with a Reliable Roll Former to explore whether partnering is right for you:

(Editor's note: This article was originally published in January 2016 and was recently updated.)

You May Also Like

These Related Stories

Power Distribution System Components: Roll Forming Benefits

Custom Roll Forming Processes: Cold Roll Forming Steel