Roll Forming Services: Your OEM & Architectural Solution

You’re looking for custom metal forming services, and you come across roll forming – but there’s two kinds: OEM and architectural.

What does an OEM roll former do? Is the process any different from architectural roll forming?

We’ll clue you in (since we do both). A roll forming company can offer parts you can use for your own brand-name product as well as metal trim moulding produced under its own line.

So ask a potential vendor about its capabilities -- you may be surprised at the versatility of custom roll forming services.

What is Roll Forming?

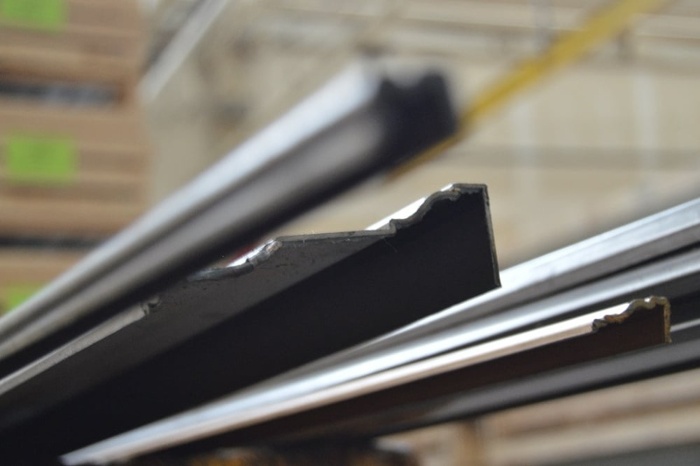

Roll forming is a cost-effective manufacturing process that involves gradually bending flat sheet metal into a uniform, longitudinal profile by passing it through a series of tool dies. This process is ideal for mass production of various components, including:

- Angles,

- Channels (C, J, Box, Hat)

- Long components with holes

- Complex shapes with multiple bends

In addition to its affordability, roll forming offers the added benefit of allowing for the easy incorporation of in-line punching features such as

- Holes

- Notches

- Slots

- Embossing

By designing these elements into custom tools during production, there's no need for slow and expensive secondary operations. As a result, roll forming helps lower production costs while reducing lead times.

OEM METAL BENDING SERVICES

Why it’s called “OEM” -- original equipment manufacturer -- is a mystery. An OEM supply company is actually one that makes products out of components manufactured by another company. That second company then sells the assembled, finished product to users under its own brand name.

So what does a custom roll forming company do for OEM buyers? They provide:

- Accurate tolerances

- Raw material procurement

- Packaging

1. Accurate Tolerances

An OEM part is more about function, so tolerance and precision are especially important. Your roll former should stick as closely as possible to the agreed-upon tolerances.

Done correctly, roll forming can hold tolerances up to +/- 0.005” on certain profile segments. Overall part lengths can be accurate up to +/- 0.020”.

(That’s not to say super-tight tolerances are the most practical ideas in metalworking.)

For example, Dahlstrom is currently making a copper conductor that slides into a PVC extrusion. It’s critical that the copper piece fits properly into the mating part -- but not so loosely that it rattles around. A manufacturer experienced in roll formed parts will know how to make your part precise and understand your mating parts -- every time.

2. Raw Material Procurement

The material we use is 100% specified by the customer. These specifications include the material’s:

- Composition

- Thickness

- Temper (hardness)

WIth OEM orders, It’s up to your vendor to make sure it can source the metal that meets those requirements.

For example, at Dahlstrom we buy the raw materials 95% of the time. We want to be 100% sure what you specify meets the criteria of the tooling Dahlstrom designed to make the part. We not only design tooling to make the profile accurate, but also with the metal’s properties in mind. In other words, we don’t just make the shape, we customize it for the properties of the metal you want.

3. Packaging

Didn’t expect this one?

A great OEM vendor should realize the packaging of your part can make a big difference to you. How you’ll assemble the part, and how quickly you’ll be able to identify it, matter.

For example, if your ordered parts are long and slender, your vendor should understand:

- How will you store them?

- How will you take them out of the box? Out of the top? By sliding them out?

- What’s the packaging material? Cardboard? Wood?

Your manufacturing partner should specify the packaging design for your convenience.

Metal Trim Moulding: Timeless & Modern

When we make an OEM part, it becomes someone else’s proprietary product. But our architectural roll forming practically has Dahlstrom’s historic name stamped on it (not literally).

The right partner can enhance your architectural project with:

- Choices

- Great looks

- Ease of use

1. Choices, Choices, Choices

A veteran moulding supplier will have a huge range of decorative metals and finishes from which you can pick. Available products include:

- Galvanized steel mouldings

- Aluminum mouldings

- Stainless steel mouldings

- Copper mouldings

- Bronze mouldings

- Brass mouldings

For architectural orders, we control the properties of the metal you select. So we’ll do the worrying for you when it comes to picking that right look of bronze for your specific application.

For architectural applications, tolerances are less important. It’s more about ID’ing the best metal, especially if your project will be outside.

2. Great Looks

In architectural cases, we’re more concerned with the features and aesthetics of the product. You can certainly specify an OEM product to be shiny, oil free, etc., but with an architectural product, it's almost 100% a decorative deal.

3. Ease of Use

Your architectural project almost certainly demands longevity, so the right vendor will offer a metal that won’t turn ugly or brittle quickly and require replacement or repairs.

Your vendor should also make sure you’re aware of the installation method. Dahlstrom’s mouldings, for example, should be installed by a professional metalworker who’s familiar with cutting and fastening metal for use as architectural trim.

Custom Roll Forming Services to Meet Your Needs

Whether you’re looking for a metal forming service for your OEM parts, or to create beautiful architectural trim and moulding, you should partner with a roll former. It’s a highly customizable and economical solution.

FIRST-TIMER? EXPERIENCED DESIGNER?

Is this the first time you’ve dealt with metal fabricating services? Or are you an experienced designer looking for a helping hand to aid you from start to finish? We might be able to help.

(This article was originally published in December 2017 and was recently updated.)

You May Also Like

These Related Stories

Sheet Metal Design Guide: End Distortion & Springback

Famous Buildings With Dahlstrom’s Architectural Roll Forming: Part II