Can Copper Antimicrobial Products Make Hospitality Design Safer?

The coronavirus pandemic has forever changed the way many of us think about architectural design and materials.

The coronavirus pandemic has forever changed the way many of us think about architectural design and materials.

Now, beyond looks and functionality, many interior designers will take public health and safety into account. One idea that’s been floated recently is increasing the use of copper antimicrobial products.

So, does copper have antimicrobial properties? Yes, it absolutely does. Some have even called copper a “molecular oxygen grenade” -- read on to find out why, and why you should consider adding copper into your next design:

Are Copper Antimicrobial Products Legitimate?

When viruses and bacteria land on a copper surface, their RNA or DNA is literally blown apart by an oxidation-reduction reaction.

This ability to destroy viruses and bacteria (without outside help) distinguishes copper from other metals, like stainless steel, as it literally disinfects itself. Other metals can’t do the job by themselves, allowing microbes to live for many hours or even days on their surfaces unless someone cleans them.

Copper actually “self-sanitizes” between physical cleanings. It doesn’t lose its germ-killing ability over time, and unlike antibiotics, it doesn’t give microbes time to mutate into strains that resist antimicrobial environments.

How Can You Use Copper to Keep Occupants Safe?

Health care-acquired infections account for around 99,000 deaths and about 1.7 million infections a year in the United States. Estimates say these infections cause hospitals $35.7 billion to $45 billion each year, so antimicrobial copper in hospitals is a no-brainer investment. But this metal, which has been used to fight infection since Phoenicians sprinkled it in their battle wounds, could defend against infectious diseases in other public spaces too:

- Universities

- Hotels

- Banks

- Commercial kitchens

- Airports

- Sports arenas

- Large offices

An aging, more susceptible U.S. population, along with increased public awareness of infections like COVID-19, creates both concern and opportunity. Firms are also looking for modern hotel room interior design ideas that set the curve -- why not use the beauty and antimicrobial properties of copper? You can create interior spaces that are not only striking, but safer as well.

Sticking with the theme of hotel interior design ideas, think of all the surfaces people touch in the span of a one-night stay:

- Handrails

- Elevator rails

- Water faucet handles

- Toilet flush handles

- Door casings & knobs

All these surfaces are potential homes for nefarious microbes, and all of them could be enlisted in the fight against infection, if they were made of antimicrobial copper alloys.

When Will Hospitality Interior Design Trends Catch Up?

John Spear, professor of civil and environmental engineering at the Colorado School of Mines, believes two main arguments exist against the widespread use of copper.

One is the green patina that eventually forms on it. Exposed copper can become flaky and transfer to other materials, such as skin and clothing. The other is that copper’s relatively high cost may scare off smaller establishments.

Fortunately, it’s not necessary to clad an entire building in antimicrobial materials and coatings. Just focus on the “touch surfaces!”

Watch the Hands

Where hands are likely to go, copper should follow.

Think of an elevator -- most have a panel of buttons for selecting a floor and a handrail. Depending on the foot traffic in and out of that building, hundreds of people may touch those components each day. A little antimicrobial copper could go a long way in fighting an outbreak.

Research reported in the New England Journal of Medicine found that hospital room surfaces with copper components have an 83% lower bacterial level than rooms using traditional materials. The study also found a 58% reduction in patient infection rates in rooms using copper components.

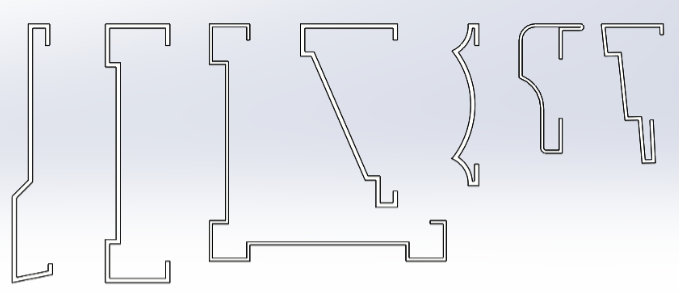

The possibilities for using antimicrobial copper in hospital interior design alone are numerous:

- Bed rails

- Call buttons

- Tray tables

- Cabinet handles

- Door handles

- Decorative metal trim

A little imagination could totally change the future of health care and hospitality interior design trends!

Will Copper Interior Design Trends Continue to Rise?

The benefits of copper in fighting pathogens is a bigger topic today due to the COVID crisis, but talk isn’t action.

While price remains a roadblock, that might be more perception than reality. Copper costs about $1.50 more per pound than stainless steel. But for large-volume projects involving architectural mouldings, that doesn’t translate to a huge increase as a percentage of overall costs. Even better, recently developed antimicrobial copper alloys are more affordable than traditional copper, while maintaining those germ-killing qualities.

The bottom line is that the use of copper will probably become more prominent in our physical environments, either because of luxury or necessity. Who knows? Five years from now, everything from hotel corridor design to airport lobby design might feature that shiny, reddish-brown glow.

You May Also Like

These Related Stories

Dahlstrom Roll Form Company Turns 115 Years Old

Pair Decorative Metal Trim Easily Via Our New Online Moulding Catalog