Copper Welding: Interior Door Casing, Seamless Crown Moulding, & More

Can you weld copper? Absolutely. The trick is establishing the ideal joining method for your application.

Here’s a look at the different processes and applications for copper welding, many of which involve the use of copper in interior design, plus how your interior framing design can benefit from them.

Welding Copper: The Possibilities

The copper welding process lends itself to several opportunities and ideas in exterior and interior design:

- How to make trim look seamless

- Interior door casing design ideas

- TIG welding copper

- Silver soldering

- Brazing for joining copper with dissimilar metals

Silicon Bronze Welding -- Seamless Mouldings

Silicon bronze is a kind of hybrid MIG welding/brazing technique. You can use a MIG welder and gun to essentially braze the materials together. Using MIG equipment and silicon bronze welding wire makes joining copper an easier, more repeatable quality process.

The silicon bronze wire heating requirements aren’t enough to melt the copper base metal. This allows you to join thinner materials with little risk of melting or warping. You’re left with a yellowish filler material that can be polished and will have a similar color to your copper base material.

How can you put this technique into action when fabricating red metals? Installing seamless crown mouldings, baseboard mouldings, and so on.

Think of a corner baseboard moulding made of copper. When that corner joint has to happen, we can use silicon bronze to make it a clean, smooth joint between two mitered pieces at the factory. A pre-mitered moulding makes field work simple by limiting cuts to straight ones only.

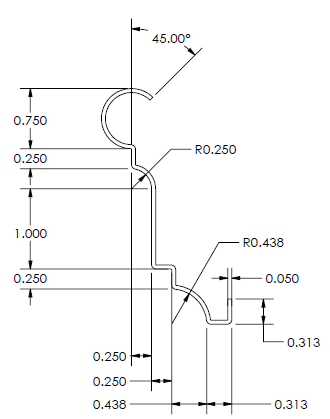

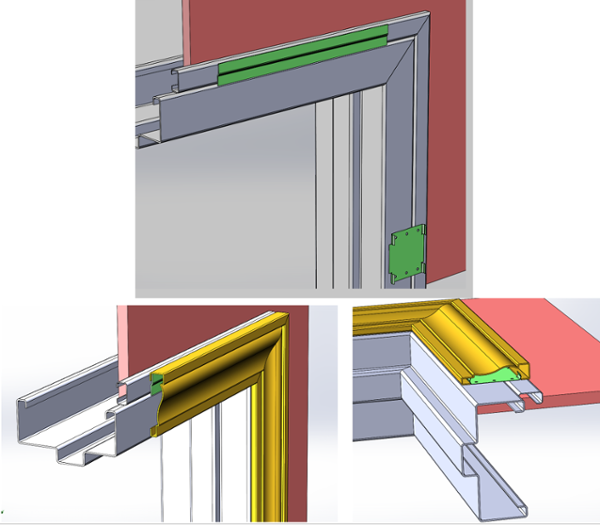

Interior Door Framing Details

You can improve your door casing design in a similar way.

See how the piece would be attached? You’re basically making a picture frame out of the copper casing and cladding a flush metal door frame. Again, Dahlstrom would use a silicon bronze welding technique for this particular door casing material.

Related article: More about seamless, pre-mitered baseboard mouldings

TIG Welding Copper

(Photo courtesy Metal Works Fabrication)

Is copper easy to weld? It depends on your plan (or your manufacturer's plan). TIG welding is an option if you’re the risk-taking type.

Due to its high conductivity, the base material (copper) acts as a heat sink, so the welds need to be hot and fast. The heat associated with this welding process will cause that thin base to warp and change shape.

If you’re welding thin material that needs to maintain its shape, TIG welding may not be for you.

Silver Soldering

(Photo courtesy etherealgirls via Instructables)

This technique is popular for jewelers and others who join precious and semiprecious metals.

Silver solder is somewhat absorbed by the metal surrounding it, and creates a joint that's actually stronger than the metal was before. However, the metal being joined must be perfectly flush, as silver solder won't adequately fill gaps.

Silver soldering requires the least amount of heat and does not deform or discolor the base metal the way welding or brazing does. The solder material does, however, leave a silver color at the seams. You can “pickle” these seams in an attempt to darken the color, but ultimately you won’t get as close to a color match as brazing or welding will.

Copper Brazing

Brazing is similar, but not the same, to welding. If you need a strong, permanent joint welding and brazing are the two best options.

Brazing is popular in jewelry making because it doesn’t melt the base metal and there are new filler wire materials available to match the metals and their colors. These wires require higher heat than a lower-temp silver solder but offer a better color match to the base metal.

Most soldering is done at temperatures ranging from 350-600 degrees F. Copper brazing is performed around 1,100-1,500 F.

More on Installing Crown Moulding & Seamless Baseboards

The end use of the item you want welded greatly impacts the joining method you should choose. Experimenting with the soldering and brazing techniques perfected by jewelry makers can produce some beautiful looks and seamless joints for high-end metal moulding installation and furniture accent projects.

When you cut metal, the resulting ends can be sharp. That tends to scare installers away. Find a crafty manufacturer who will pre-miter and pre-weld your decorative metal trim. By smoothing out these corners in the factory, you’ll avoid having a dangerously sharp edge where the two points meet. Remember also that Dahlstrom Architectural Mouldings’ optional pre-fabricated 90-degree joints can use any of our metal mouldings in not only copper, but brass and bronze as well.

As always with metal design components, let’s be creative, and let’s work with installation-ready accents! To see how for yourself how it works, get your hands on a free sample below:

(This article was originally published in August 2018 and was recently updated.)

You May Also Like

These Related Stories

So You're Installing Commercial Metal Trim Moulding ... Now What?

5 Uses for Metal Picture Rail Mouldings to Kick-Start Your Creativity