Metal Door Frame Casing: Avoiding Aesthetic Flaws & 3 Other Benefits

The status quo isn’t going to advance your designs. Sometimes you need to reassess what’s always been considered "acceptable" and see it for what it is -- kinda ugly. A door casing is a prime example of an opportunity to take the “ugly” and turn it in to something beautiful.

The status quo isn’t going to advance your designs. Sometimes you need to reassess what’s always been considered "acceptable" and see it for what it is -- kinda ugly. A door casing is a prime example of an opportunity to take the “ugly” and turn it in to something beautiful.

What makes a metal door frame casing worth the (easy) installation?

Metal Door Frame Casing: A Primer

There are four key benefits of metal door casing:

- Attractiveness

- Ease of installation

- Uniqueness

- Fire safety

Let's talk about what a “pre-fab” door casing made from metal can do. (We’d love you if your doors themselves were steel too, but wooden doors are acceptable). This type of moulding hangs tightly from the head jamb and snaps solidly into clips attached to the side jambs.

The high-end styling of metal door casings can bolster the architecture of:

- Hotels

- Restaurants

- Retail spaces

- High-end residences

4 Reasons You Need Door Casing

4 Reasons You Need Door Casing

1. Attractiveness

If you look at any door frame, you're going to see a square, bent piece of metal. Designers have lived with this square door frame for years.

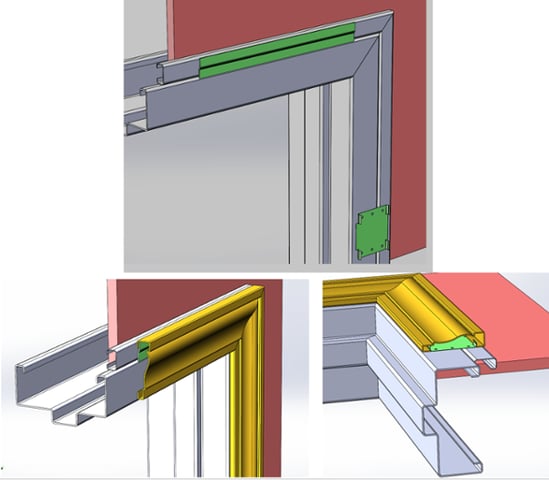

We’re developing a clipping system that allows you to snap metal trim over that ugly frame and turn it into something ornate, whether the frame is newly installed or it has been there for 20 years.

Check out the example on the right -- looks better already, doesn't it?

2. Ease of Installation

Like window casing, door casing is traditionally installed as separate pieces.

There are two ways to do a door frame.

One is to have two vertical pieces and one horizontal part. You create a 90-degree angle and snap on the door frame.

The second option is to weld the two top corners together. It looks like a door frame, but it’s actually a metal moulding (or a metal door frame -- whatever you want to call it). The vertical pieces are long for easy field cutting, but the width is fixed and is easy to determine because there so few door widths. (The top three door width options make up 90% of the market.)

The second process results in a huge reduction in installation time. If you know what you’re doing, you can install the piece in 15 minutes easily. Whoever set up the original door frame will be capable of installing this casing themselves -- no additional experts needed.

3. Uniqueness

As of now, nobody else thinks to do this with their doors. You’ll stand out and be ahead of the curve with a product like this.

Maybe you’ll even start a trend!

4. Fire Safety

Steel mouldings (or, say, stainless steel) are fire resistant. Just another reason metal casings beat wooden ones.

We're confident that our mouldings do not burn. However, always check with the door and frame manufacturer to be sure fire testing is not affected by what you plan on doing with our mouldings.

What More Do You Need to Know?

Want to be the trendsetter? Be the first in your architectural circle to put an end to ugly door frames. If you want to learn more about metal door casing, get in touch with us today or click the graphic below for a free sample.

And, now that you’re a master of doors, perhaps your windows could use some steel!

(Editor's Note: This article was originally published in December 2017 and was recently updated.)

You May Also Like

These Related Stories

Metal Door Casing Ideas for Interior & Exterior Designers

Copper Welding: Interior Door Casing, Seamless Crown Moulding, & More