VIDEO: Wood Vs. Architectural Metal Mouldings Part 2 - Scrape Test

Many architectural projects must back up their beauty with backbone. It’s not enough to create a great design -- it’s got to stand up to wear and tear in a mass-shared space, too.

That’s why this video series attempts to answer, "What is the most durable type of base trim in the industry?" Wood mouldings? Vinyl mouldings? Architectural metal mouldings?

We put five materials through an abrasion, or scuffing, test. The goal: How do popular mouldings react to a glancing blow as might occur in a hotel, airport, or other public place?

Related videoS and Article:

Architectural Metal Mouldings Vs. the World: Why Perform a Scrape Test?

Durability matters. There are plenty of common instances where scraping or scuffing may occur to architectural mouldings. You can probably think of many yourself, but here are a few:

-

Airport corridors and other transportation areas. Lots of foot traffic and suitcases banging around the halls. Huge floor polishers trying to reach every nook and cranny. Don’t forget about the metal food carts -- they move around on big metal casters that can really do some damage.

-

Hotels. Lots of traffic, carts, and suitcases rolling around. Frequent use of vacuum cleaners. Cleaning carts that service people use to spruce up hotel rooms.

-

Hospitals. Gurneys and other traffic moving with urgency -- and therefore little care for the nearby architecture. Cleaning carts, food carts with metal casters, floor polishers -- you name it.

Wood, Composite, Vinyl, & Architectural Metal Mouldings Comparison

To test each material, we used a wood-carving tool -- not sharp like a razor, but definitely something with an edge to it. Here are the results: (See the above video for a better look!)

1. Pine

This is the softest wood commonly used for architectural mouldings, but also the most prevalent because it’s quite economical.

You can see in this test that pine gets marked up fairly easily due to its inherent softness. Any material that has grain -- like pine -- can splinter when it sustains an angled impact. This only accentuates the blemishes.

Pine is really tough to maintain for maintenance workers in a high-traffic facility. Imagine what this moulding would look like after a few months of abuse in a crowded public space!

2. Medium-Density Fiberboard (MDF)

Medium-density fiberboard is a composite material that includes wood, resin, and wax. It’s a very dense product used in residential and commercial construction. Think of it as a weaker version of plywood.

Again, this is a material that’s very prevalent in the industry and not very expensive.

… Not surprisingly, commodity nature of this product is reflected in its performance. It reacts even worse than solid wood. MDF is a pressed material with a binder in it, so it’s not adept at dealing with side abrasions.

Medium-density fiberboard does avoid the splintering issues that can affect traditional wood mouldings. However, once MDF takes damage it can flake further if the inner core becomes exposed. So, if it takes repeated hits, you’re in trouble.

We haven’t done a water test, but we can guarantee you MDF will also have issues with taking on moisture -- not good if your durability needs go beyond impact resistance.

3. Solid Oak

Known for both its beauty and its outrageous price, oak can run $5-$8 per lineal foot, and that's before you specify the final finishing. Naturally, oak mainly sees use in high-end installations.

Solid oak is one of the harder woods used for interior mouldings. And it shows -- oak performs quite a bit better on our test than the first two moulding materials. But, still, some visible damage is clear.

Just like with pine, an angled impact can cause oak to splinter and accentuate the imperfections that already exist. Blame it on the grain of the wood.

4. Vinyl

This inexpensive material is very common and readily available.

It also failed our test miserably.

An abrasion from a sharp surface will heavily damage vinyl. This material, being soft and pliable, is simply unable to stand up to an angled blow.

Even worse, you’re stuck with the damage. You can put putty over wood and paint it. Vinyl, though, turns white at the scuffing site. There’s no good way to fix it.

Dealing with beat-up vinyl architectural moulding gets further complicated. Vinyl has to be glued on, and it has to be peeled off for replacement.

Your sworn duty as a designer in a high-traffic area is to stay very far away from vinyl.

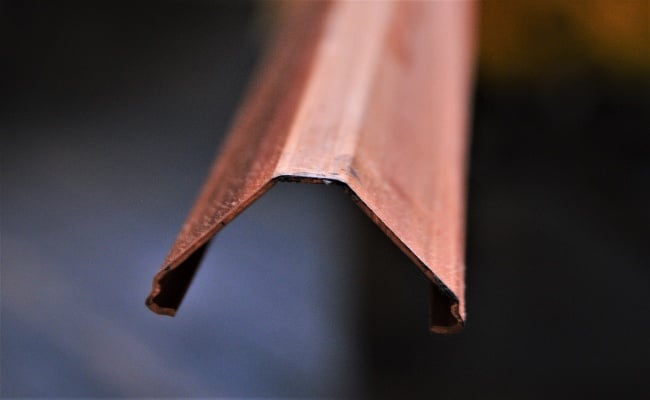

5. Steel

The fun part about using architectural metal mouldings is that there are nearly endless possibilities in varieties and finishes. There are over 500 different steel moulding varieties at Dahlstrom alone.

“Steel” can mean more than just standard steel. Galvanized steel can give you additional protection against corrosion outdoors, for example.

If you’re working with a smaller budget, don’t worry -- metal mouldings aren’t quite the money sink you’d think. They’re $1-$2 per lineal foot and won’t rot or become infested with disgusting bugs.

As for impact resistance … what you see is just a little surface abrasion. There no denting upon impact, and no change in the actual shape of the material. It resists hazards quite nicely!

A long-lasting moulding drastically reduces your worries about repair or replacement. (Not to mention there are other benefits of using steel mouldings vs. wood mouldings.)

And even if your steel or red metal moulding does get dinged up, the hypnotizing shine (especially in stainless steel) often distracts from any imperfections.

Coming Soon: Part 3

As the tests show, architectural metal mouldings are ideal for high-traffic commercial applications.

But we’re not stopping here in our effort to decisively declare the most durable moulding. We have one more test to go in our series of moulding beatdowns. Part 3 will feature the ultimate trial for any architectural material: the flame test.

Keep checking in as we continue to determine the most durable architectural moulding products. Or, if you can’t wait and want to see the video versions of our research right away, click below:

CHECK OUT THE VIDEO PREVIEW NOW:

You May Also Like

These Related Stories

VIDEO: Wood Vs. Architectural Metal Mouldings Part 1 - Impact Test

A Vendor Can Take Your Architectural Metal Mouldings to Another Level