Should You Buy and Install Decorative Metal Trim? Or Wood?

Metal or wood? It’s a question too few designers ask. When researching decorative trim, getting the best look possible is probably first on your priority list. Installation time and cost may also be weighing on your mind.

Metal or wood? It’s a question too few designers ask. When researching decorative trim, getting the best look possible is probably first on your priority list. Installation time and cost may also be weighing on your mind.

Considering decorative metal trim over old-school wood? Wondering if it can give you the look you want at a reasonable time and money investment? Let’s examine the differences in style, ease of use, and cost.

If you need more information about the physical properties (i.e. fire resistance, sturdiness) of metal vs. wood, read up here.

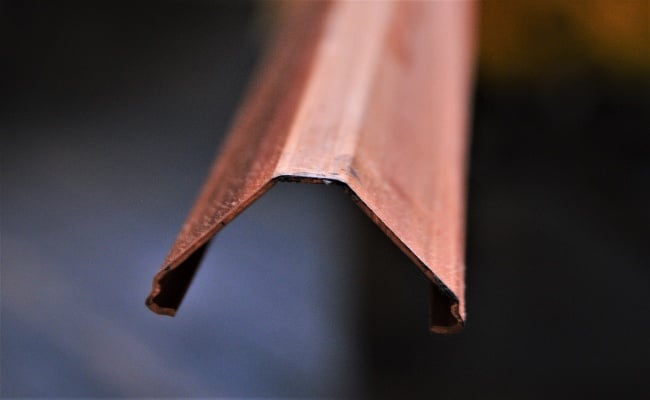

Decorative Metal Trim

1. Style

The grain on a piece of wood is mesmerizing -- the natural swirl of hues makes wood uniquely special. You can paint wood in any color and can be waxed and varnished which’ll brandish its natural finesse.

Wood provides a rustic, homey appearance to any residence, hotel, or other place of business.

Its inviting look even has measurable physiological and psychological health benefits, according to research. Workers are less stressed, students learn better, and patients heal faster in spaces with natural elements.

With metal, whether it’s bronze, copper, or another type, you’ll be a pioneer in something virtually nobody else is doing (until you start a trend!).

If you’re an architect, chances are you don’t want your work to be like anyone else’s. Sometimes you don’t even want to be like yourself -- metal’s a great way to break the monotony of wood design.

Metal mouldings are uniquely beautiful. Your imagination can run wild!

2. Ease of Use

Wood makes for an easy installation. It’s lightweight and low in density, so it can be moved around without a hassle.

Want the highest degree of prefabrication and rapid assembly possible? You can carve, cut, nail, and glue wood with ease.

But … does it drive you nuts when a project requires so many trips to the work site? Metal offers major benefits, especially when you have a tight turnaround requirement.

Say you’re putting in painted wood (the most common material in construction):

- You cut it, shoot little nails in it, and install it.

- Someone else fills those nail holes with wood filler.

- That person waits for it to dry, then caulks it, then paints it finally.

- Finally, said painter returns to apply a second coat.

You and the second person have to make a combined four trips at least. Whew.

Compare that with installation of a bronze or galvanized steel moulding.

- You install it.

The end. The metal’s beauty is in its finish, so you can skip all the painting steps. (Although you can still paint it if you wish.)

Metal mouldings allow you to compress your installation schedule. It might take longer to install the metal because of cutting and other needs, but you’re only there once. Often you’ll find that wood installers don’t come back right away because they’re tied up with several other jobs. If you need them three times, that adds up quickly.

3. Cost

If you polled America about which material is more expensive, you can bet a lot of people would say metal.

Here’s the truth about primed wood vs. primed painted metal. If the volume requested is high enough your vendor should be able to sell pre-primed steel mouldings for less than $1 per foot.

Even on the high end of the price spectrum, metal may beat high-end woods. At the right vendor you can find bronze for about $8-$10 a foot. You can’t even sniff the most expensive natural woods -- oak, maple, cherry -- for that money.

Check Out the Top Metal Mouldings

Metal and wood can actually co-exist and complement each other aesthetically. Feel free to mix and match.

If you love the sound of metal and are wondering where to go next, feel free to study up some more on the traits of top metal mouldings. Happy hunting!

You May Also Like

These Related Stories

Is Wood Trim Outdated? Introducing Decorative Metal Trim

A Vendor Can Take Your Architectural Metal Mouldings to Another Level