Top 10 Metal Standard Moulding Profiles Loved by Architects/Designers

Metal mouldings will add impressive value to your project, whether you’re an architectural engineer or an interior designer. Those seeking high-end quality for their product will benefit in almost every case from choosing metal over wood moulding profiles. That’s why designers frame windows, doors, and storefronts with metal; and accent living spaces with metal baseboards, chair rails, cornices, and vertical battens.

Metal mouldings will add impressive value to your project, whether you’re an architectural engineer or an interior designer. Those seeking high-end quality for their product will benefit in almost every case from choosing metal over wood moulding profiles. That’s why designers frame windows, doors, and storefronts with metal; and accent living spaces with metal baseboards, chair rails, cornices, and vertical battens.

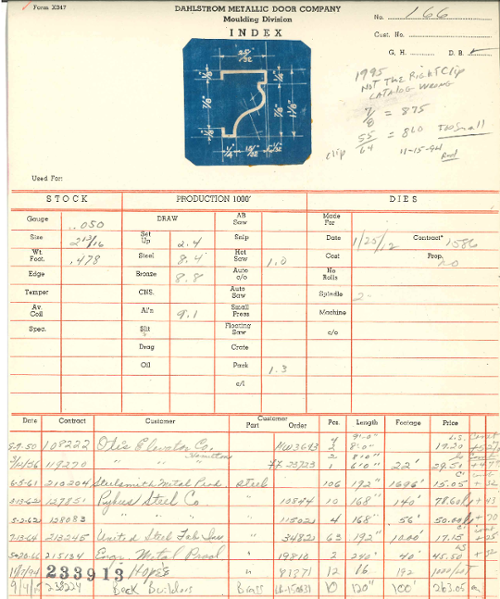

Dahlstrom been the premier supplier of metal mouldings since 1904, and it shows: We’ve got more than 1,400 unique exterior and interior moulding profiles.

Based on number and volume of orders, we’ve compiled Dahlstrom’s top 10 standard moulding profiles:

(Or see the full catalog here!)

Why Should Metal Be the Standard for Moulding Profiles?

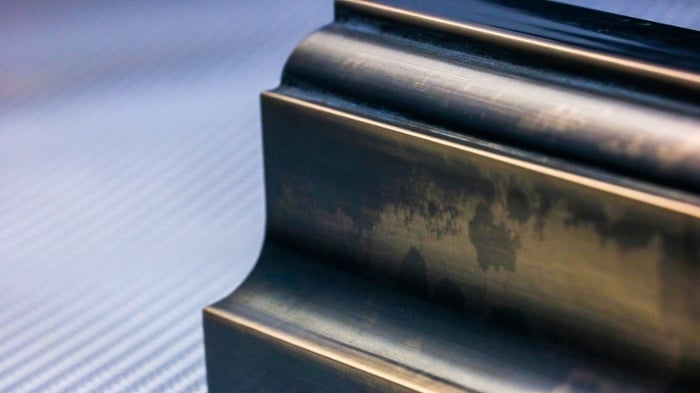

Metal mouldings are known for their looks. The sleek, modern appearance of metal is valued in many commercial residential designs.

But we also urge you to decide on a moulding vendor based on the functional benefits these pieces should provide. They include:

- Impact resistance: They’re metal. Of course these mouldings are tougher than wood!

- Wear resistance: They don’t rot or grow mold, and many metal grades offer excellent corrosion protection.

- Fireproof: A moulding should not become fuel or smoke for a fire that breaks out.

- Versatile materials: Our mouldings are available in commercial steel, galvanized steel, stainless steel, aluminum, copper, bronze, and brass.

- Authenticity: We form our mouldings using tools originally designed over a century ago.

- Sustainability: Are you green-minded? Steel that’s 100% recycled should always be an option.

Our vast offering of unique metal shapes is available nowhere else in the world. And these shapes offer all of the benefits listed above.

But what do our customers think is the best of the best?

Top 10 Standard Moulding Profiles

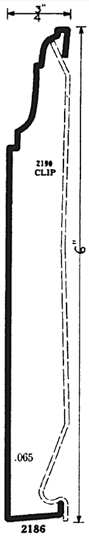

10. #2186

This is one of our tallest and most dramatic baseboard moulding profiles.

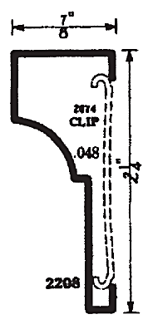

9. #2208

9. #2208

Number 2208 is one of our most versatile interior design mouldings. This shape can be used as a:

- Door frame moulding profile

- Subtle crown moulding profile

- Chair rail moulding profile

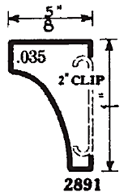

8. #2891

This cove moulding is typically used to soften right-angle transitions.

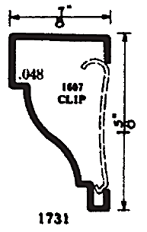

7. #1731

You can use the #1731 window and door moulding profile to create impressive depth on frames.

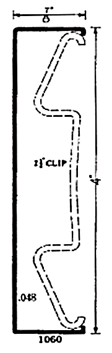

6. #1060

A straightforward design, #1060 is often used as a baseboard or chair rail.

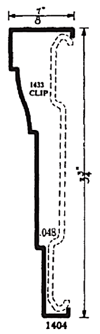

5. #1404

This profile is a simple, yet quietly detailed shape used as a baseboard moulding profile or door frame accent. You will find our #1404 displayed throughout the famous Paramount Building at Times Square in New York City.

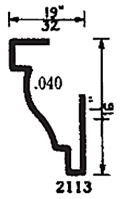

4. #2113

This versatile moulding is most commonly used as a window sash accent or decorative glass stop.

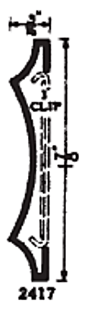

3. #2417

We most often product this fluted design as a:

- Copper moulding

- Brass moulding

- Bronze moulding

It makes for a great chair rail moulding or vertical wall panel separator. Our #2417 is featured extensively throughout Le Meridien hotel in New York City.

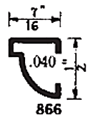

2. #866

This small moulding is typically used to accent custom cabinetry or to frame inlaid panels on doors.

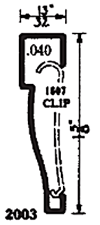

1. #2003

Our #2003 is one of the most ubiquitous moulding shapes in the world. … However, this one is made of metal.

How Do Architectural Metal Mouldings Fit Your Design?

If you are unable to find in our moulding profile catalog the shape you need, Dahlstrom can design and produce a custom component that meets your specifications. Architects and interior designers looking to class up their design can choose from an unparalleled variety of trim, casing, and more.

Contact us if you need more help understanding metal mouldings, or request a quote today if you’re ready to buy.

(Editor's note: This article was originally published in December 2017 and was recently updated.)

You May Also Like

These Related Stories

10 Oldest Metal Architectural Mouldings That Can Still Be Made Today

Metal Mouldings 101: The Dahlstrom Bedrock