5 Surprisingly Common U Channel Edge Trim Applications

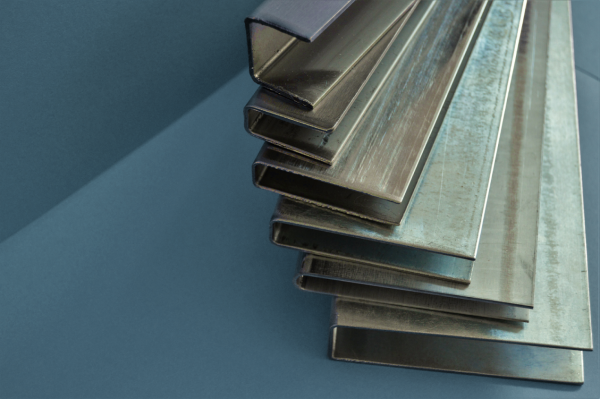

What Is U channel edge trim?

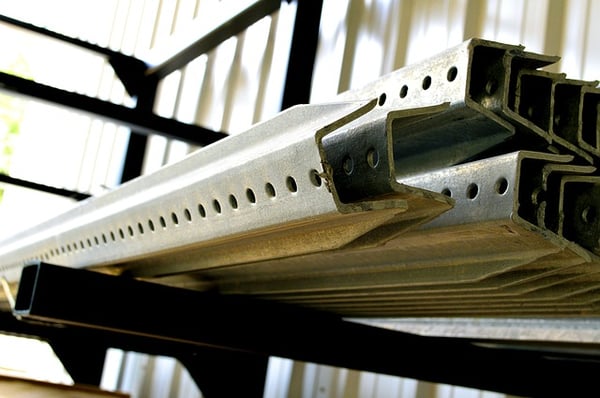

First off, a U channel is a tall, skinny, metal formed product. Deeper channels (a little deeper and more narrow than what you see above) can only be achieved through roll forming. Other forming methods can reach into the U shape as well as they can with standard steel channels. So if you’re looking for an especially deep U channel, take a look at MeshTrim here.

U channel metal edge trim gets lots of love for its ability to frame thin panel and mesh products. This includes metal fabrics, glass panels, wire mesh, and other flat panel items.

Benefits of U Channel Edge Trim

Without further ado, the top benefits of U channel trim include ...

- No more sharp edges

- Attractive structural edging

- Reduced fabrication costs (sometimes)

1. Eliminates Sharp Edges

In many applications, the naturally sharp edges of wire mesh and metal panels are undesirable and even detrimental to their intended use. This is true in the case of animal cages, screen doors, and other items that humans and animals use daily.

In these cases, we want to eliminate injuries and snagging associated with sharp edges. U channel trim fits perfectly over the edges to create a safe and attractive frame for your product.

2. Attractive Structural Edging

U channels are also a viable architectural trim solution. Most architects try to avoid a bare mesh or panel edge -- it’s simply not as attractive as a framed edge. U channels can be made from a variety of metals to suit any architect’s or engineer’s aesthetic needs:

- Stainless steel U channel trim

- Aluminum U channel trim

- Many other materials

3. In Some Applications, Reduces Fabrication Costs

A frame that covers the entire perimeter of your product can remove the need for costly fabrications.

5 Smart U Channel Edge Trim Applications

1. Woven Wire Mesh

Wire mesh, also called wire cloth or metal fabric, is required for many daily life and specialty applications. These include:

- Fences (security and animal)

- Animal cages

- Screens

- Industrial conveyor belts

- Filtration

- Materials handling

- Architecture

As mentioned above, many of these products come into contact with humans and animals daily, making U edging for wire mesh a must. Wire mesh edging protects users from injuries and snags from all the products above, and then some.

2. Architectural Metal Panel Products

Metal panel products are very desirable in modern architecture. They’re sleek, professional, and futuristic. Metal panel edge trim can be used in both:

- Architectural and structural wall panels

- Construction of commercial and industrial buildings

You can also find corrugated metal panel trim. In all of these cases, metal U channel trim moulding provides attractive architectural framing and expanded design opportunities.

3. Glass Panels

Everyone is familiar with glass paneling. But have you touched it up with the class of metal? Here are some exciting ideas:

- U channel window trim

- Metal-edged glass photo frame channels

- Chrome trim for glass shower panel

- Safety barriers

Stainless steel U channel trim, for example, accentuates glass panel products by providing an outline for the eye to follow. Metal framing enhances the delicate aesthetic quality of glass architecture.

4. Railings

U channels are used as trim for hand and stair railings, including escalators, in commercial spaces. Metal railings are easier to maintain and longer-lasting than their plastic or wood counterparts.

5. Tracks

Metal U channels are perfect for commercial and industrial tracks. Consider the following uses for metal here:

- Wheel cover trim

- U channel track roller guides

- Sliding door trim

- Automated machinery channels

Tracks are a functional must for these products. Why not make them beautiful while you're at it?

Can Metal U Channels Elevate Your Product?

If you're interested in a standard steel channel (or a different metal type or shape), contact your favorite roll former to find out more.

If you're interested in an extremely deep or tall channel, MeshTrim might be a more optimized solution for you. Check out our MeshTrim page or download our free guide to MeshTrim below to learn more:

(Editor's note: This article was originally published in January 2016 and was recently updated.)

You May Also Like

These Related Stories

How U Channel Trim Moulding Completes Wire Mesh & Architectural Panels

What Goes Into Roll Formed C & U Channel Prices?