How U Channel Trim Moulding Completes Wire Mesh & Architectural Panels

A great roll formed steel U channel can do wonders for your project’s cost- and time effectiveness. That’s why we create …

5 Surprisingly Common U Channel Edge Trim Applications

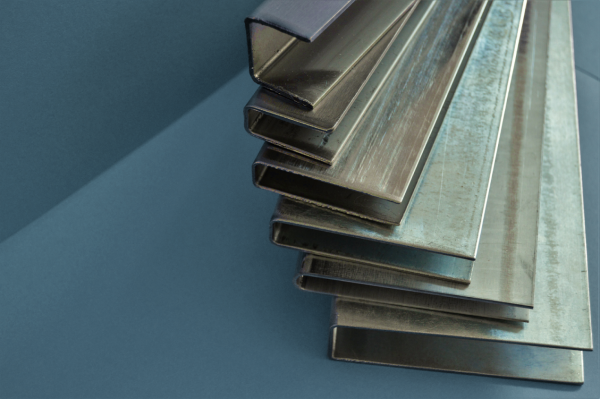

What Is U channel edge trim? First off, a U channel is a tall, skinny, metal formed product. Deeper channels (a little d …

MeshTrim: Custom Framing for Decorative Wire Mesh

As an architectural designer, the last thing you want is a creative barrier.

Create a Streamlined Supply Chain for Wire Mesh Frame

MeshTrim is the most versatile woven wire mesh frame choice in the world. No, the universe.

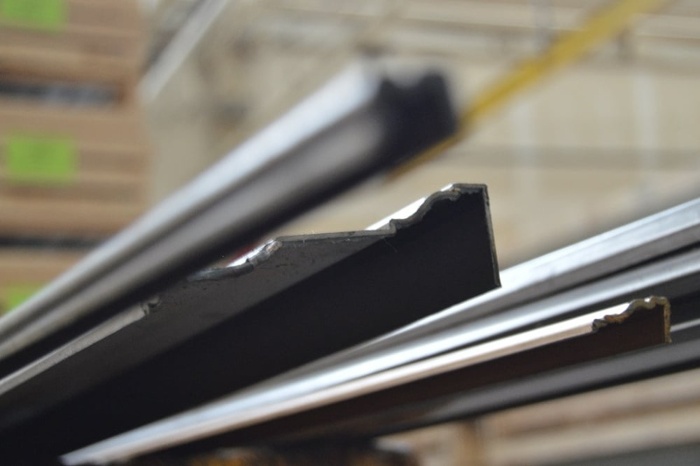

Roll Forming: A Versatile Sheet Metal Punching Partner

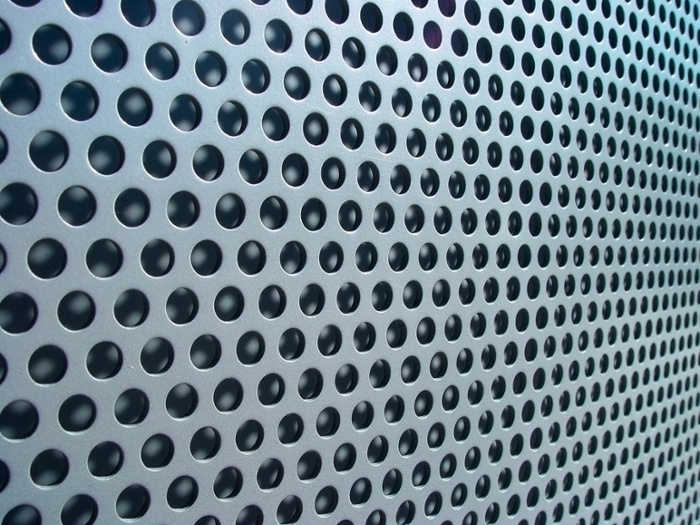

Roll formed components often require hole punching -- after all, that’s probably one reason why you chose roll forming t …

Sheet Metal Design Guide: End Distortion & Springback

Roll forming is the most cost-effective way to continuously produce complex shapes with multiple bends. But it’s not a p …

What Goes Into Roll Formed C & U Channel Prices?

To manufacturers, a channel is one of the most simplistic shapes on earth. This helps explain why channels are a commodi …

Architectural Wire Mesh & Perforated Metal Panels: 3 Benefits, 10 Uses

Architectural design aims to balance economy, elegance, and efficiency. Perforated metal paneling and wire mesh certainl …

Supply System/Manufacturing Process Improvement Example: Roll Forming

Manufacturing process improvement can be tricky! We all want to improve our manufacturing processes and create added pro …