Using Total Quality Management in Manufacturing for Long-Term Success

Today, customers expect high-quality products and services more than ever. But how can businesses ensure consistent qual …

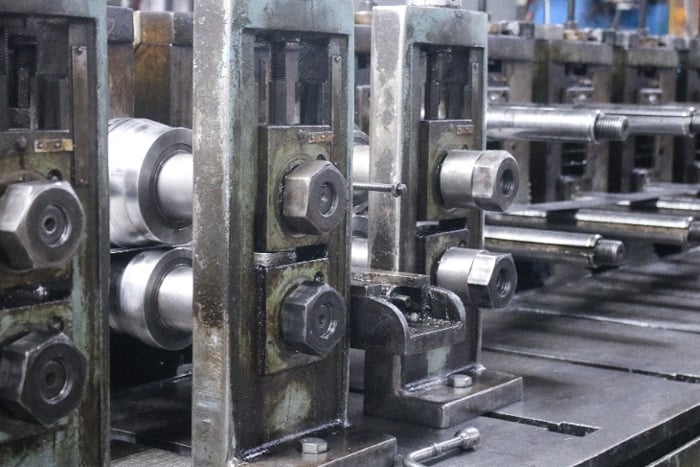

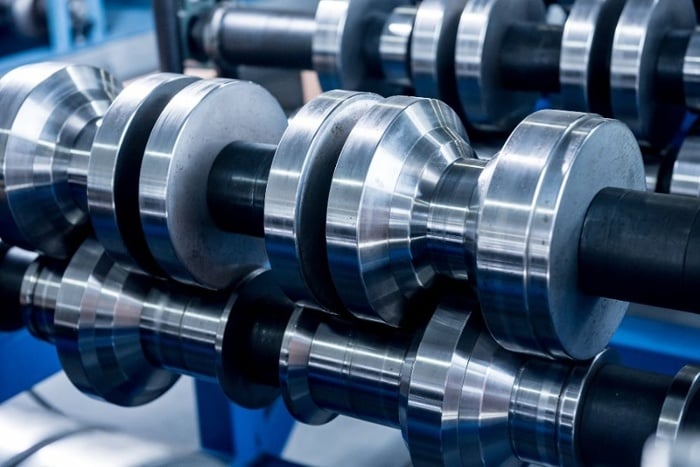

Understanding The Roll Form Tooling Process

As far as metal forming techniques go, roll forming has long been a standard for OEMs. You’re probably already familiar …

Metal Forming Processes: Industries & Applications

Metal forming processes play a crucial role in powering our society, driving innovation across industries. They enable t …

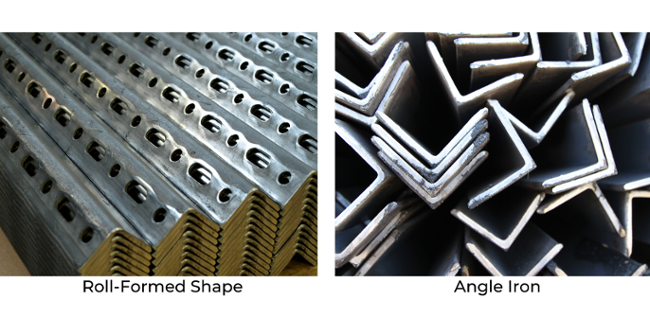

Need a metallic L-angle? Roll Forming vs. Angle Iron

You need long, slender, L-shaped metal components for your project. Several metal forming processes can achieve the desi …

6 Important Factors in Manufacturing a Solar Racking System

Solar energy is thriving in the United States, fueled by an impressive 24% average annual growth rate over the past deca …

Custom Roll Forming Processes: Cold Roll Forming Steel

Metal fabrication can be complex, but there are certain methods that can be used to make it simpler and more efficient.

Can Outsourcing 1 Part to a Metal Roll Forming Company Boost Profits?

U.S. manufacturing has had its share of bad turns over the last 50 years, with entire industries being outsourced to oth …

Theory of Constraints: How to Shore Up Your Manufacturing Weaknesses

Every manufacturing setup has limits in achieving its goals. The Theory of Constraints (TOC) is a management methodology …