U.S. manufacturing has had its share of bad turns over the last 50 years, with entire industries being outsourced to other parts of the world. This is not good news for metal roll forming companies.

Starting with products like clothing and electronics, we gradually saw large corporations move their production overseas or to South America to take advantage of cheaper labor and less regulation. In the 1970s, the trend continued with auto parts, furniture, toys, shoes, and a host of other items.

Fast forward to today, and we may be seeing a more influential recognition of the value that U.S. manufacturing has to offer, such as:

- Rapid response of supply in close proximity to the largest group of consumers in the world

- The lowest energy costs in the world

- Highly advanced technology and automation

- A fairly stable political and market environment

But as a manufacturer anywhere, what if you could outsource just one component of your finished product to a local metal roll forming company and increase your shippable units by 20% to 50%? How could this possibly happen?

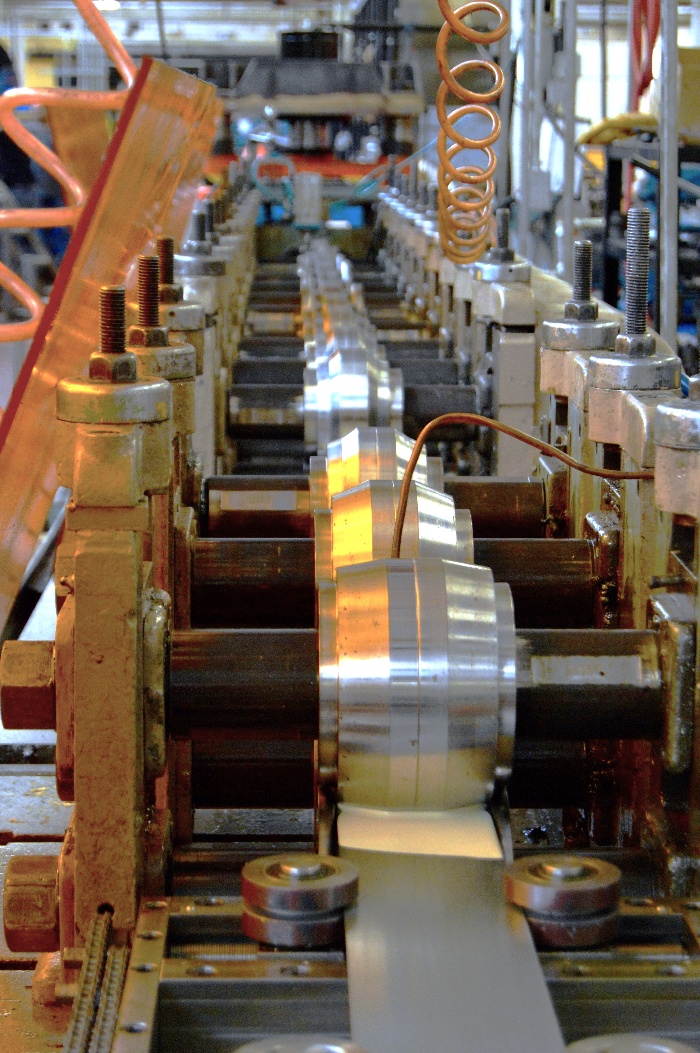

When to Turn to Metal Roll Forming Companies

Almost all manufacturers have equipment and processes designed to provide customized features inherent to the uniqueness of their products. Whether these features contribute to the unique functioning of the product or allow the manufacturer to offer customers options, they form the core value and differentiation that support sales. It makes sense that investment in equipment, people, processes, and allocation of factory space should favor supporting these features of the product.

Many manufacturers tend to want to use equipment not only for unique, value-driven components of the product but also for more generic commodity components as well.

A plant manager's dream would be to have 100% utilization of their equipment and resources in order to get the maximum return on their investment.

But, what if the available capacity for producing the true, value-driven components is consumed by the commodity components? What if the highly skilled labor that understands the custom processes is banging out generic widgets? Have lead times increased because we are so busy? Is the sales group screaming for more custom units with options that need to ship faster? Looks like we have a conflict.

(Resource: Find out how roll forming services can help your business affordably produce the parts you need.)

If you would like to take a deep dive into the aspects that go into creating a great roll formed part, check out our free e-book below: