The Hidden Expense: Roll Forming Raw Material Cost

OEM projects can be hectic. Your main concerns are likely lead time, reliability, quality, customer satisfaction, and controlling manufacturing costs.

Unfortunately, you may not think about the costs associated with raw materials as much because they’re a necessary part of your operation.

But what if you could reduce those raw material costs?

By working with a custom roll forming corporation that discloses the facts about the largest cost component of your parts, you may uncover cost-saving opportunities.

If you're the manufacturer, you may benefit as well. As it turns out, customers reward the efforts of sellers who lay out pricing elements in full view. This is backed by research of general business practices, but most definitely applies to roll formed parts as well.

So, when you ask your manufacturer how to reduce roll forming raw material costs, make sure you're getting the full answer.

Your Roll Forming Company (Should) Know How to Reduce Raw Material Costs ...

There are three factors that affect roll forming costs:

- Setup Time — the amount of time it takes to insert and remove the roller die tools from the roll forming machine

- Run Speed — the speed at which you can feed metal through the machine

- Materials — the raw materials needed for the project

Of the three, roll forming raw material costs make up the biggest expense — anywhere from 40-80% of the final manufacturing cost.

What is the biggest factor in raw material costs?

Unfortunately, it varies. However, for a lot of industries that buy formed metal products, pricing can consist of:

- True rolled-up cost of raw materials (mill price + servicing cost + freight + ...).

- How much metal is contained per linear foot of finished product.

- How much the metal thickness varies and how that affects you.

- How much scrap figures into the final price.

Additionally, the share of part cost that raw material contributes depends on:

- The amount of metal in the part

- The type & thickness of the raw material

- How much scrap is produced in the process

- Metal market conditions

Unfortunately, failure to understand how to calculate raw material costs creates an opportunity for manufacturers to profit from your misunderstanding. That’s why it’s essential to find a roll forming company that is reliable and trustworthy and will disclose raw material prices openly.

Falling Prices Slow to be Passed Along

Think of the gasoline industry. When the price of petroleum goes up, a seller tends to make the customer’s gas price go up very quickly. But when the price goes down, that change happens much slower. No one enjoys that.

Sure, some higher-priced gas remains in the seller’s inventory and needs to be covered cost-wise, but when do they really tap into the lower-priced supply? Is the lower cost passed on immediately?

The raw material market changes all the time in metal manufacturing too. And many manufacturers sprint to the phone to contact customers during times of the high cost of raw materials ... but not so quickly on the downswing.

Instead of staying true to the market, there may be several pennies skimmed off the top.

One Roll Forming Company's Raw Material Philosophy

Let’s face it: Once you have a complete understanding of a sheet steel supply chain, why should your vendor try to hide anything? Your roll forming company should be performing raw material cost analyses on a regular basis and sharing that information with you.

Additionally, roll forming companies should practice transparency with customers by offering a structured quarterly review process as part of their standard roll forming service package. This includes:

- Current market trends

- Consumption rates and inventory levels

- Bids for material to cover the next production period

- Steel mill lead times

The Case for Vendor-Managed Inventory

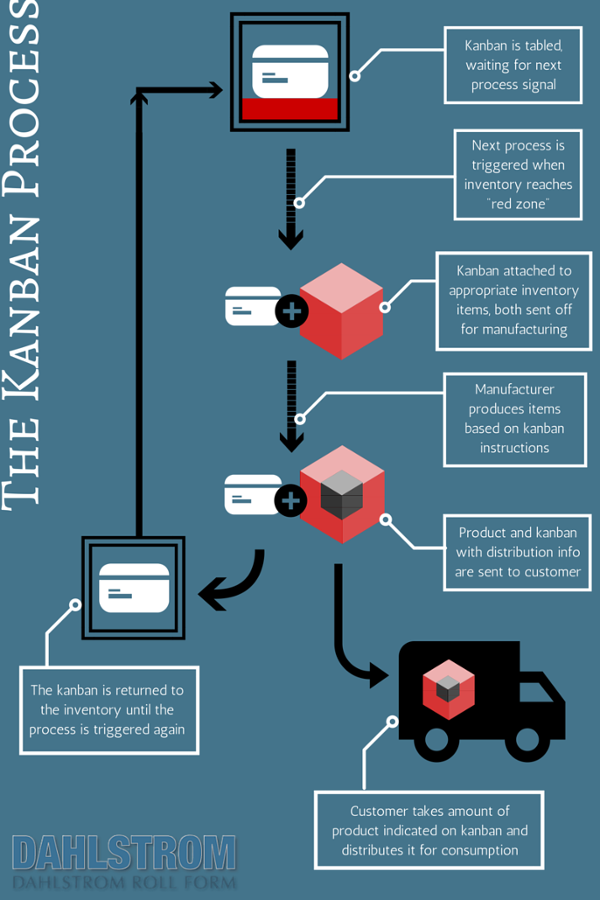

The whole point of this exercise is to help manage costs and expectations. The easiest way to do that is with vendor-managed inventory.

Vendor-managed inventory programs offer a collaborative approach to inventory management within the roll forming industry. In a typical VMI program, OEM client shares product consumption forecasts with the roll forming supplier. This information empowers the supplier to strategically manage inventory levels, ensuring a mutually beneficial stock that meets the client's ongoing needs. This shared-risk approach fosters a more integrated supply chain relationship.

This system is ideal for customers with repetitive, ongoing production requirements. Each system is tailored by product demand but is fundamentally based upon just-in-time delivery and pull system concepts.

Benefits include:

- Lower investment in inventory

- Reduction in administrative costs

- Better logistics management

When seeking a roll forming manufacturer, prioritizing a company with extensive experience in lean manufacturing systems is crucial. Look for a partner with a proven track record in successfully implementing and operating VMI programs. For example, Dahlstrom has a successful history of constructing and operating VMI systems since 1996.

Raw Material Costs & Inventory Management

When done correctly, under the guidance of an experienced partner, metal roll forming is one of the most efficient and cost-effective methods of metal shaping. Get more information on roll forming raw material costs and inventory management best practices.

Download our free guide to Streamline Your Roll Forming Costs

(Editor's note: This article was originally published in March 2018 and was recently updated.)

You May Also Like

These Related Stories

Keep Roll Forming Costs Under Control With Kanban Inventory Management

Choosing the Right Path: Roll Forming vs. Other Metal Parts Manufacturing Processes