How Roll Forming Limits Your Total Manufacturing Cost of Ownership

When it comes to metal forming cost, if price is the battle, total manufacturing cost of ownership or -- TCO -- is the war.

TCO is an analysis of the complete life cycle of your purchase. The number includes every phase of ownership.

Parts with a lower TCO are better in the long run when it comes to roll forming cost -- even if the initial purchase price is higher.

Are you getting the most out of your roll former? Keep reading -- and check out this TCO calculator.

(Want to learn how to streamline your roll forming costs? Download our FREE guide below.)

Defining YOUR Roll Forming Total Manufacturing Cost

A total manufacturing cost analysis highlights the difference between the purchase price and long-term cost. It consists of:

- Equipment and material costs: These include the cost of equipment, but also installation and any necessary upgrades.

- Personnel costs: These include in-house staff and any outsourced help. Ongoing employee training, project management, and resources for rejects/rework also factor in here.

- Operating costs: These include inventory, utility costs, waste disposal, and more. Your run time efficiency once you receive the parts is key here.

- Shipping/transport: How efficient is your vendor?

These factors all play into long-term maintenance and investment in quality. The right manufacturer can help you lower your total manufacturing cost of ownership.

Equipment and Material Costs

Involving our engineers early in the component design phase lets Dahlstrom develop economical roll forming tooling. That philosophy can also help us minimize raw material costs by helping to design a part with a better structural cross-section using thinner metal. Furthermore, we will make intelligent material purchases to keep direct materials costs low as the market for metals changes.

You’ll find it’s no small thing to avoid paying for tooling. With our MeshTrim product, for example, we offer no-cost tooling for hundreds of U-channel size combinations. Our catalog is an accumulation of many years of roll forming and offers shapes from existing tooling that may meet your needs.

If you need to buy your own tools, you’ll find Dahlstrom knows its way around a bunch of creative payment and financing options, so don’t worry.

Personnel Costs

Dahlstrom’s internal personnel costs are part of our cost and protect you in many ways:

- Lean operating practices

- Continuous process flow

- “Pit crew” machine setup philosophy

- Intensive employee cross-training

These practices contribute to our competitive sell price.

Your manufacturing overhead costs are controlled by our industry-leading customer service and reliability. Our quarterly customer review process makes sure we understand your changing needs and that those needs are communicated back to our entire manufacturing team. Our on-time delivery percentage of 99.5% and our field reject PPM of fewer than 4,000 guarantees that we will execute correctly and on time. Planning and executing correctly lets your people spend more time on your business.

Operating Costs

Roll forming is the most economical production process for the bending of metal channels, angles, and complex shapes. We’ve been doing it the right way for nearly 120 years.

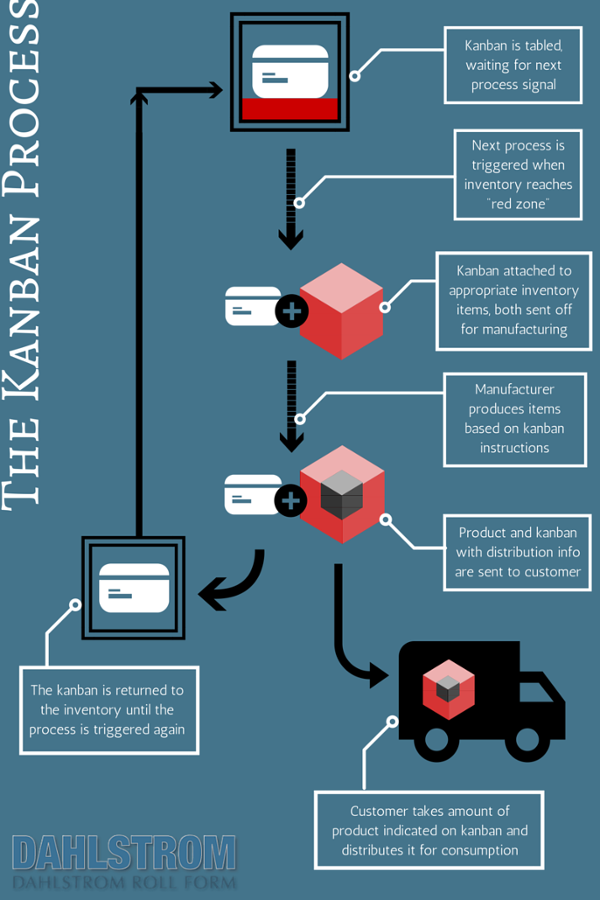

We can produce a lot of parts in a short amount of time. This is why Dahlstrom offers inventory management to further manage your operating expenses. Benefits of vendor-managed inventory include reduced inventory investment and lower administrative costs. Dahlstrom also keeps it lean with the Kanban philosophy. We use point-of-use feedback to develop the ideal, seasonally adjusted system so you don’t buy more than you need … and more importantly, you don't run out.

Shipping/Transport

If your product requires secondary operations or minor assembly, Dahlstrom can add them to the end of the roll forming line. Doing this instead of adding a separate line or shipping your parts to another manufacturer saves you money.

And when you are ready to order, our logistics folks can work with your current manufacturing shipping companies or use our own to get you the best freight rate. We will always make sure we balance trailer utilization with your inventory system.

Go with a Versatile Manufacturer and Keep Your Total Manufacturing Costs Low

A well-rounded manufacturer knows not only how to make great parts, but also guides you from start to finish and controls your long-term metal forming costs. If you’d like assistance lowering your total cost of ownership, request a quote today.

Click below to see our services and capabilities.

(Editor's note: This article was originally published in September 2017, and has recently been updated.)

You May Also Like

These Related Stories

Supply System/Manufacturing Process Improvement Example: Roll Forming

.jpg)

7 Pitches to Sway Your Boss to Switch to Roll Formed Metal Components