The Benefits of Using a Full-Service Roll Forming Company

Full-service roll forming companies should give you expert advice, help you design quality parts, and find ways to keep your costs low.

For example, your roll former should involve its engineers at the very onset of your component design. This ensures your parts come out in the most efficient and economical way.

This is just a taste of the full-service experience you deserve and should expect from metal roll forming companies.

WHAT ARE FULL-SERVICE METAL ROLL FORMING COMPANIES?

When working with a single-source roll former or a dual-source roll former, you can expect the benefits of collaborative engineering, like:

Choosing a full-service metal roll forming company, whether single-source or dual-source, comes with the advantage of collaborative engineering. These companies offer:

- Expert advice on selecting the best material for your application

- The ability to eliminate costly, time-consuming secondary operations by identifying opportunities to integrate punching holes, notches, or tabs directly using roll forming tools

- Enhancements to your new design to ensure seamless integration with other components in your system

What Should a Quality Roll-Forming Company Offer?

A quality roll former should understand your business’s unique requirements and anticipate how external factors might impact the unit cost of your part. These factors include:

- Fluctuations in material prices

- Long-term improvements in packaging

- Producing smaller batches to accommodate shifting demand

Need a better metal forming process for your components? See what Dahlstrom Roll Form can do for you:

THE BENEFITS OF CHOOSING THE RIGHT ROLL FORMING COMPANY

Don’t settle for a supplier-OEM relationship that’s simply a trade of money for roll-formed parts. A roll former's multilevel service package should include:

- Setup time reduction

- Informed material buys

- Monitored performance data

- Dynamic inventory management

- Supply system reviews

- Tooling ownership

- Economic runs

1. Setup Time Reduction

Your manufacturer should use a "pit crew"-style setup team to minimize machine downtime. This allows you to order small cycles when necessary while keeping fabrication costs low.

2. Informed Material Buys

The benefits of roll forming are minimized if your supplier isn't actively helping you achieve cost savings.

A reliable roll former will maintain transparency with raw material costs and closely monitor steel and other material markets. By proactively advising you on material pricing trends and passing savings along, your supplier can ensure cost-effective procurement.

3. Monitored Performance Data

Does your roll former back up its claims?

Your partner should make sure your roll-formed shapes arrive on time and meet your quality expectations. For reference, Dahlstrom consistently achieves an on-time delivery rate of 99.5% and a field quality defect of fewer than 4,000 parts per million (PPM).

4. Dynamic Inventory Management

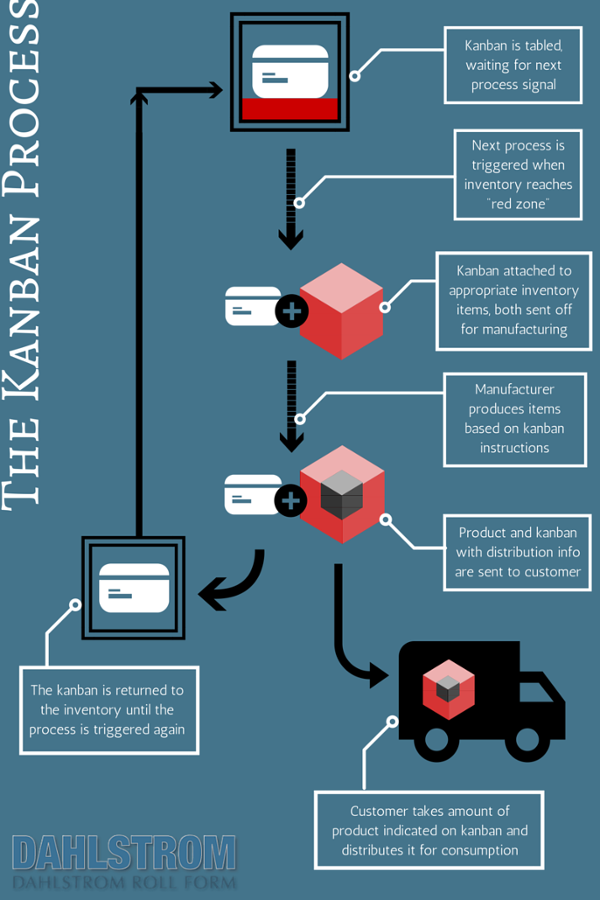

Your manufacturer should employ point-of-use feedback to develop the ideal Kanban consumption profile for your company. A seasonally adjusted, simple Kanban system results in immediate component availability while inventory turns remain high.

5. Supply System Reviews

Any good supplier meets with customers regularly to discuss:

- Detailed usage data

- Raw material pipeline status and market price trends

- Any potential component design or process changes

This keeps all parties on the same page and ahead of the curve should issues develop within the supply chain.

6. Tooling Ownership

The supplier may even “go in” with you on tooling. Cost amortization allows you to keep full ownership of tooling and avoid hidden fees. Depending on the awesomeness of your partner, you may get:

- Lower total cost of ownership: Amortization lowers upfront expenses.

- Long-term ROI: Ownership lets you use the tooling for future projects.

- Flexibility: Some manufacturers allow you to take your tooling elsewhere if needed.

7. Economic Runs

You should strongly consider sticking with roll formers that offer economic order-quantity runs. These manufacturers will hold your inventory and distribute it to you as needed. Economic runs maximize volume and reduce setup time, without leaving you high and dry.

You can also approach your roll forming supplier about discounting small orders in exchange for a longer contract. The result may be a win for both sides.

ROLL FORMING AT DAHLSTROM

The roll forming process is complicated, but definitely worth it … with the right partner.

When it comes to supplying original equipment components, Dahlstrom is the leading roll forming service in the world, with nearly 120 years of experience.

Our quality system metrics equal those of world-class companies 10x larger than us. We work with you to develop a full-service package that guarantees we understand your consumption profile as well as you do.

If you have interest in a roll forming supply system that has the capacity and agility to meet the dynamic needs of your fast-paced industry, contact us below.

Looking to Keep Costs Low?

Are you concerned with keeping your budget in line? Read our guide to see how you can keep your roll-forming costs low.

(Editor's note: This article was originally published in January 2016 and was recently updated.)

You May Also Like

These Related Stories

6 Ways to Get More Out of Your OEM Metal Roll Forming Process

Keep Roll Forming Costs Under Control With Kanban Inventory Management