Share this

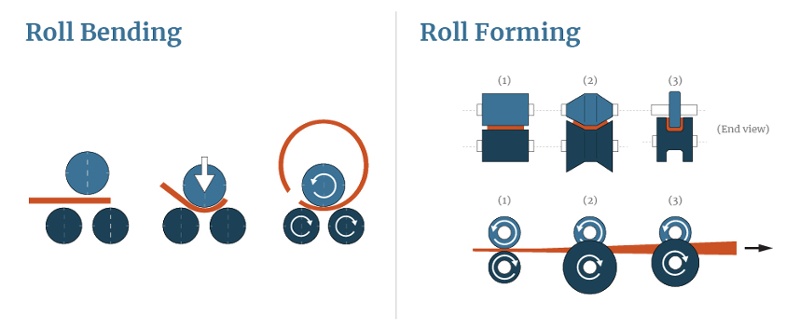

We’re often asked if we can make metal cylinders or “rings.” And while these things are made with a rolling process, that process is not roll forming, it's called roll bending.

For example, as a roll forming company, we can make a “U” channel in a straight, 10-foot length. But we can’t turn that channel into a circle. You’ll need a roll bender for that.

Roll forming and roll bending are two types of metal fabrication processes that involve gently reshaping metal into functional shapes. However, there are significant differences between roll forming and roll bending, and for which situations they are best suited.

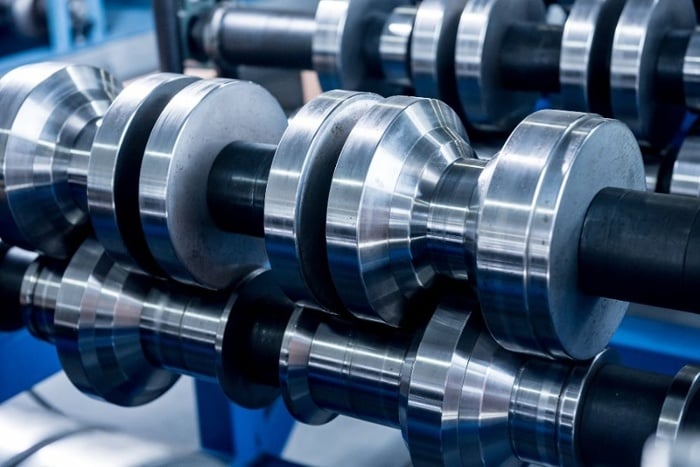

Roll forming turns a coiled strip of sheet metal into the desired shape by passing that metal through a progressive series of mated dies.

Roll forming is a cost-effective way to achieve the production of long, complex metal shapes with multiple bends and/or punch patterns. It is popular for high-volume projects like:

You see roll formed products all the time. For example, guide rails on the highway are usually manufactured using this metal fabrication method.

Roll bending takes large metal sheets and turns them into curved forms, like:

With roll bending, flat sheets of metal are passed through a series of rollers that bend the metal to the desired radius.

Types of roll bending machines include:

Roll bending is used in the production of many familiar components like:

You probably see things made from roll bending daily. For example, the housing of an airplane engine is made using roll bending.

Hopefully, by now we’ve made it clear that roll forming and roll bending are two entirely different metal fabrication processes. That being said, we certainly understand how they are often confused with each other. So as a simple reminder:

At Dahlstrom Roll Form, we specialize in roll forming, not roll bending.

Download our free e-book, How to Design a Great Roll Formed Part. It’s a great introductory resource for those looking to understand this manufacturing process.

These Related Stories

Since 1904, Dahlstrom Roll Form has been crafting top-tier, custom roll formed products with a commitment to quality, on-time delivery, and personalized service.