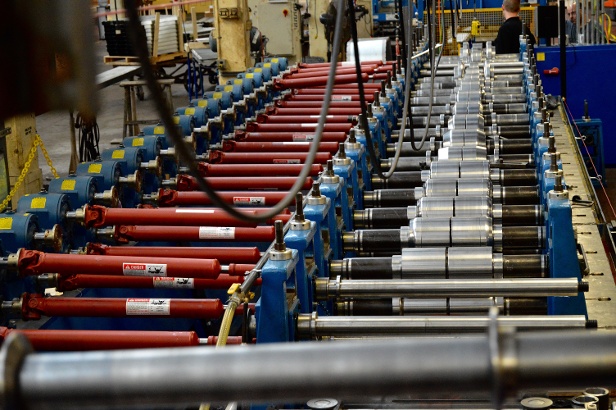

A Metal Roll Forming Partner Mustn't Be Big to Boost Your Business

Are you searching for a manufacturing partner capable of producing large quantities of products? Who is both efficient a …

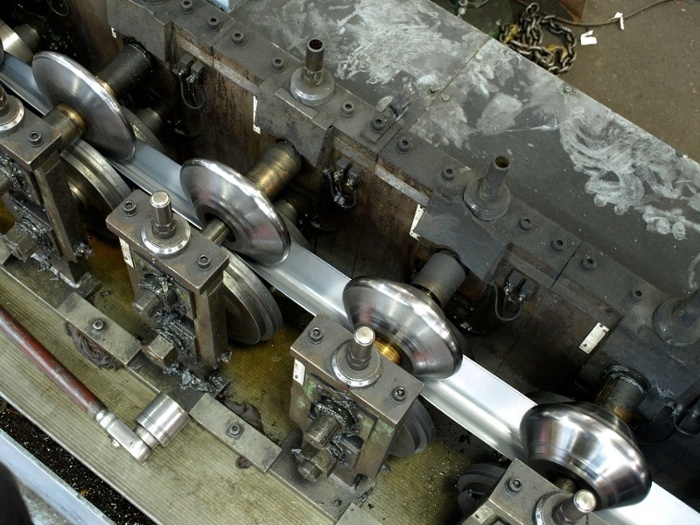

Outsourcing Roll Forming Tooling: Cost Savings Down the Line

Tooling costs in manufacturing are already a sore spot for many purchasers, but some think roll form tooling is cost-pro …

The 4 Most Common Myths of Roll Forming Metal

There are a lot of common misconceptions about roll forming metal. Four of the most common myths about the roll forming …

VIDEO: The Shortcut to Better Structural Steel Mechanical Properties

The strength of steel and its alloys has come a long way.

Why Get Custom Roll Forming From a Single Source?

For manufacturers who require a continuous flow of custom roll forming, late shipments and stock outages can negatively …

Architectural Building Materials: Does Brass Rust?

Brass is one of the great luxury metals, alongside copper and bronze. It’s considered to be an architectural building ma …

What’s the Environmental Impact of Brass Architecture?

More than ever, architects and designers are seeking sustainable ways to do business. Their minds soon bend to recyclabl …

Is Copper Architecture Sustainable?

With sustainable construction becoming so much more important to architects and designers in recent years, much of the f …