A Metal Roll Forming Partner Mustn't Be Big to Boost Your Business

Are you searching for a manufacturing partner capable of producing large quantities of products? Who is both efficient and good at communication?

Consider working with a small or mid-sized roll forming company to get the job done right.

A METAL ROLL FORMER Doesn't Need to BE A GIANT

An original equipment manufacturer (OEM) can benefit greatly from partnering with a small or mid-sized metal roll former. Some of the advantages of working with a more closely-knit operation include:

- The same high standards as larger manufacturers

- Custom, vendor-managed inventory systems

- A dynamic in-house engineering team

- Reliable tools that the manufacturer is happy to share

Learn How Partnering With a Reliable Metal Roll Former Can Boost Your Business

Download our free guide for more information:

1. The Same High Standards as Larger Roll Form Industries

If they're willing to put in the investment, smaller roll forming companies can run a great operation, too.

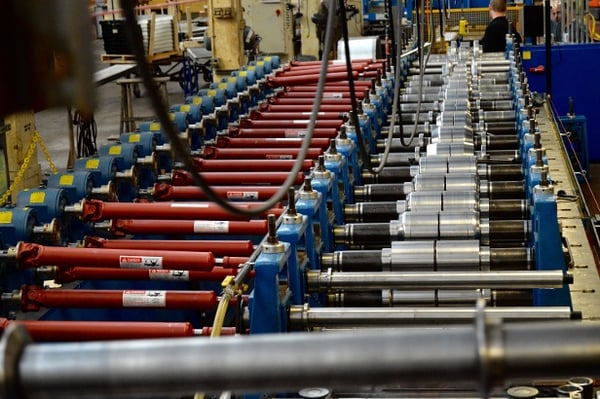

Several of these minor manufacturers are completely ISO-certified to adapt to constantly evolving manufacturing quality standards. They frequently use advanced metal roll forming machines to make shapes for top manufacturers around the world.

A just-right size allows a roll formed parts manufacturer to focus on doing great work for a handful of OEMs. That's always better than a supplier spreading itself too thin and letting quality suffer.

2. Custom Vendor-Managed Inventory Systems

A roll former should have no problem storing your stuff — and only just the right amount. This is easier when you have a close, long-term relationship with a partner capable of giving your supply chain the attention it needs.

A roll former should provide custom inventory management specifically to your company's product demand. Its fundamental roots should sprout from just-in-time (JIT) delivery and pull system concepts.

A vendor-managed inventory program can:

- Reduce inventory investment

- Lower administrative costs

- Free up space in your building

- Improve logistics management

A customer-friendly precision roll forming business will collaborate with you to build a strategic material purchasing plan. Your manufacturer is aware of the raw materials market and should be monitoring long-term trends and predictions. The right partner will have the expertise to get your materials at an optimal price, based on market movement.

3. A Dynamic In-House Engineering Team

The way you design your roll-formed component impacts:

- Overall costs

- Lead times

- High-quality consistency

So why wouldn't you work with a manufacturer that has the time and experience to help you succeed?

Like other sheet metal manufacturing processes, roll forming has its quirks and pitfalls. Working closely with a small team on the vendor's side may better educate you on how to optimize your roll formed products. This not only implies efficiency but also cost-effectiveness!

4. Reliable Tools It's Happy to Share

Do you seek precision metal manufacturing, but fear the investment required for custom roll forming tools? A small or mid-sized metal roll former can help you out there, too.

For example, our more than 120 years of work have left us with more than 500 sets of Dahlstrom-owned tools. All of them are available for your use, at no additional cost.

Consequently, Dahlstrom Roll Form is capable of producing low-to-medium-sized orders that range from 100-5,000 linear feet. This is a service not typically offered by other metal roll forming companies. Check out our catalog to see the shapes our metal forming tools produce.

If you're considering a different manufacturer, inquire about the amount of pre-existing equipment they already possess. This could significantly cut down your roll forming costs.

Want to Keep Your Roll-Forming Costs Down?

We understand the importance of closely monitoring your budget. Learn how a precision metal forming company can improve your processes and make them more cost-effective. Download the free e-book below:

MORE TIPS FOR A HAPPY PARTNERSHIP With a metal roll former

Your metal roll forming partner should remain flexible and meet the ever-changing needs of its customers.

Establishing a supply agreement with your collaborator ensures mutual understanding and alignment of the roll forming process.

The benefits include:

- Cost savings

- Reliability

- Knowing the specifications of your supply system

FAQs About Working With Smaller Metal Roll Formers

How Do Smaller Metal Roll Forming Companies Handle Large-Scale Projects If They Lack the Size of Bigger Manufacturers?

Smaller metal roll forming companies can handle large projects by focusing on their unique production abilities. They also maintain close connections with their clients to effectively meet their needs. This approach allows them to successfully take on large projects. Smaller plants may not make as much, but they make up for it with flexibility, custom solutions, and quicker turnaround times.

What Specific ISO Certifications Should a Small or Mid-Sized Roll-Former Hold to Ensure Quality and Reliability?

When evaluating a small or mid-sized roll-forming manufacturer, look for ISO 9001 certification. This standard ensures that the company adheres to quality management principles. These principles include focusing on customers, involving top management, using a process approach, and always improving. This certification is a good indicator of reliable and consistent quality.

Compared to Bigger Companies, How Fast Can a Smaller Metal Roll Former Respond to Changes in Design or Production Needs?

Smaller metal roll formers typically have a faster response time because of their lean operations and closer customer relationships. They can often implement design changes or adjust production schedules more quickly than larger manufacturers. The company is agile because they have direct communication lines and prioritizes customer service. This allows them to quickly adjust to meet client needs.

Want to Work With A Quality Roll Forming Partner?

Contact us today to learn more about how we can help your project.

(Editor's note: This article was originally published in January 2016 and was recently updated.)

You May Also Like

These Related Stories

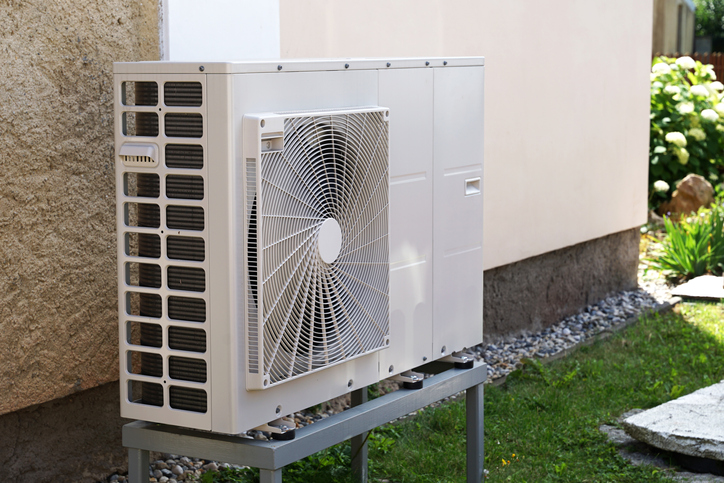

High-Quality Heat Pump Parts: Try Metal Roll Forming

The 4 Most Common Myths of Roll Forming Metal