How Vendor Managed Inventory Benefits Your Bottom Line

Maintaining an inventory of what a client needs for production is a delicate and complicated balance. As inventory ages, it can depreciate to a level that no longer adds value for the producer. This is especially true in metal forming processes.

Not surprisingly, if an OEM holds inventory that collects dust for too long, it can negatively affect the company's bottom line or force it to ship unwanted products to its clients. Vendor managed inventories (VMI) are great in preventing this from happening.

Vendor managed inventory benefits clients by taking the oversight of stock levels off of their plates.

What Are the Benefits of Vendor Managed Inventory?

Vendor managed inventory logistics allow you to have accurate forecasts so that avoid holding excess inventory.

Benefits of VMI include:

- Less investment in inventory

- Lower administrative costs

- Better management of logistics

Less Investment in Inventory

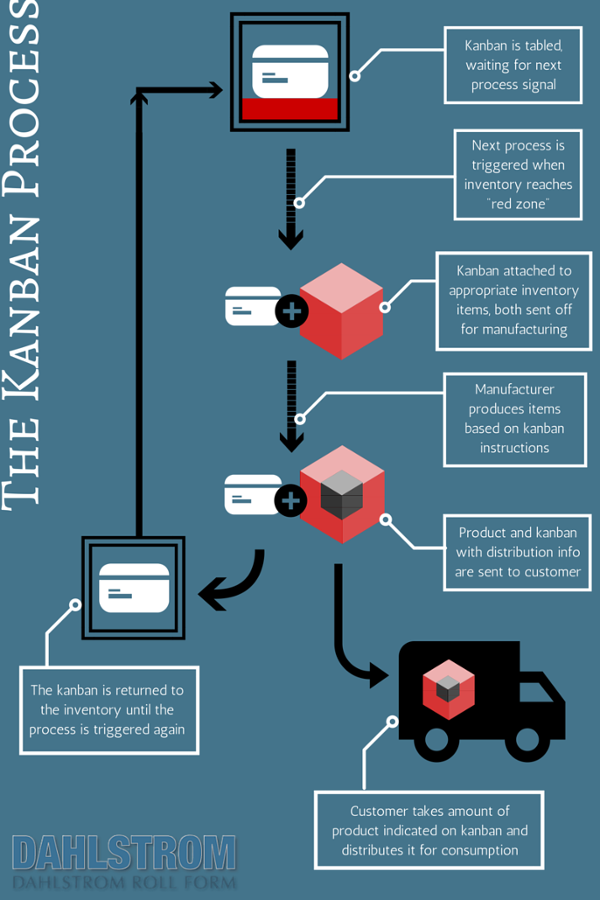

The most cost-effective and dependable style of inventory management is Kanban-based trigger-response. In this system, you provide the trigger information directly from the point of use, while your supplier responds via a robust replenishment system.

This management style works for both raw materials on the manufacturer’s production floor, as well as your finished products. Once a replenishment signal triggers, your stock is automatically refilled to a predetermined level. As a result, you avoid wasting money managing orders and delivery dates or stocking up needlessly.

Lower Administrative Costs

Equipment adjustment techniques take years to master. Experts are very expensive to hire full-time for your operations. And, if you need service contractors, they very likely will not have schedules that meet your urgent needs. That puts your supply chain and your clients at risk.

Better Management of Logistics

As you increase the number of suppliers involved in your project, you create a complex chain of communication. The more cooks in the kitchen, the more inflated the risk for mistakes is.

This can cause significant stress on your procurement and logistics teams.

Subscribing to a single-source model of roll forming production:

- Simplifies communication

- Eases the quality assurance process

- Lowers transaction costs

- Lessens lead times

Why Custom Roll Forming Should Always Include Vendor Managed Inventory

To avoid the pitfalls of aged products, some custom roll forming companies have turned to proven methods of lean manufacturing, such as vendor managed inventory systems.

In a typical roll forming VMI program, the OEM client provides a product-consumption forecast to the roll forming supplier. The supplier then takes responsibility for maintaining a mutually beneficial amount of inventory for that item. This is a shared-risk program, often referred to as "integrated supply."

When looking for a roll form manufacturer, look for one that's been perfecting lean manufacturing systems over a long period. (For reference, at Dahlstrom, we've successfully constructed and operated vendor-managed inventory systems since 1996.)

Each plan should be tailored specifically to your company's product demand. Just-in-time (JIT) delivery and pull system concepts should form the foundation of these custom services. Much like VMI as a whole, the concept of just-in-time delivery revolves around producing parts based on client demand instead of predicted demand.

Moving Away From In-House

Some companies keep the roll forming process in-house because they want tight control over inventory levels. But how does that stack up against the cost of producing your roll-formed parts?

- Can you afford to spare a current employee to work as a full-time roll forming line operator?

- Can you hire teams to take on high-volume projects?

- Can you afford the massive up-front cost and ongoing maintenance work that comes with in-house roll form work?

Third-party roll-forming experts already have balanced systems in place that keep your project affordable.

Roll Forming Services That Meet You in the Middle

A vendor managed inventory agreement is a big part of any strong supplier/client relationship. Your metal forming company should go over the numbers with you quarterly. That includes looking at the supply flow from prior months and your expectations or major projects for upcoming months.

Want to learn more about how a vendor-managed inventory program can reduce investment and administrative costs, all while improving your logistics management? Drop us a line here. If you need more advice on how to trim your manufacturing costs, check out the free e-book below:

(Editor's note: This article was originally published in January 2016 and was recently updated.)

You May Also Like

These Related Stories

Keep Roll Forming Costs Under Control With Kanban Inventory Management

JIT Delivery: 1 Step a Roll Forming Manufacturer Must Take