JIT Delivery: 1 Step a Roll Forming Manufacturer Must Take

There’s nothing new or mysterious about “just-in-time” or JIT manufacturing. The idea has been around since the 1970s, and all it means is that you receive what you need, just when you need it -- hence the popular term just-in-time delivery.

There’s nothing new or mysterious about “just-in-time” or JIT manufacturing. The idea has been around since the 1970s, and all it means is that you receive what you need, just when you need it -- hence the popular term just-in-time delivery.

Yet, when it first came into practice, it shook up metal forming. Why? Let's answer the question from the specific point of view of working with a roll forming manufacturer.

How Does JIT delivery Work?

Good question. Before answering, it should be said that, when everything that goes into supply system management -- including elements of JIT manufacturing -- is looked at together, it’s not so simple.

Now, to answer the question of why JIT shook up manufacturing: On the manufacturer’s side, JIT production reduced inventory drastically. No longer did raw materials or finished roll formed metal sit around and pile up, stealing valuable space and increasing storage costs.

The stuff had to be paid for, whether used in a week or 10 years or never. And, of course, that cost had to be passed along to customers.

On the customers’ side, the just in time manufacturing process meant their parts or finished products would arrive as they were needed, so they wouldn’t stack up and cost money before they could be used. In other words, the whole supply stream benefited as customers became suppliers and so on down the line.

Essentially, JIT delivery is part of an overall approach to manufacturing efficiency that minimizes inventory, reduces costs, boosts productivity, and keeps up with customer demand.

What JIT Means When Working With a Roll Forming Manufacturer

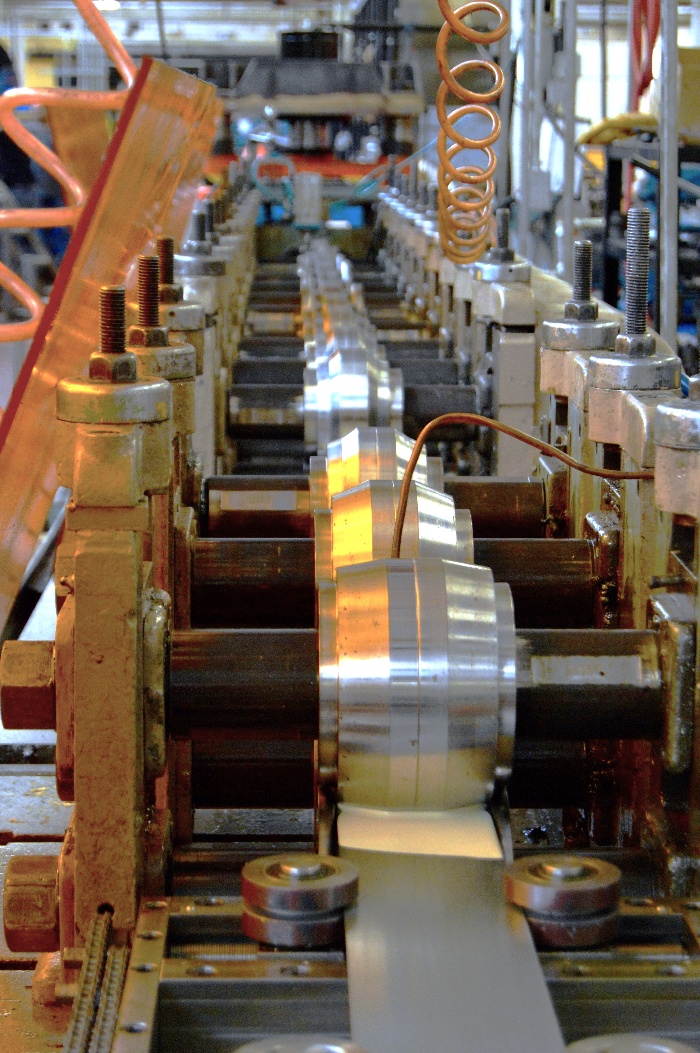

At a reputable roll forming company, just in time manufacturing is essential to a system that has one purpose: to make sure the company doesn’t make too many components for a customer or run out of product when it’s in demand. Essentially, it’s a production process based on inventory management at both ends of the process -- raw materials and finished goods -- which, in turn, become the customer’s raw materials.

It’s easy to see how things could go wrong with a system that doesn’t have a lot of give to it. One miscommunication about what product should be where when can screw everything up and make the system collapse like a line of dominoes. That’s why the real key to successful just in time logistics and supply system management is customer service.

Communication is Crucial

Good customer service is mostly good communication. Dahlstrom is one of many companies that use JIT manufacturing. We conduct quarterly reviews with customers to:

- Look at consumption data and answer questions about the parts we make for the customer. The information allows customers to conduct their own investigation into their usage and needs.

- Adjust the estimated annual usage (EAU) data used to run the system. Trigger points for releasing additional materials are based on the amount taken the previous time versus the "live" EAU plan.

- Determine customer plans or changes for the future.

These quarterly get-togethers are helpful from the start, but after a couple of years, they become extremely valuable in understanding customers’ inventory use in peak and slow seasons.

How Do JIT & Supply System Management Work in the Right Situation?

With good customer communication in place, inventory management techniques can function at their best. Here’s a quick look at two just in time delivery examples that help Dahlstrom Roll Form control its inventory yet still respond to customer needs in a timely way.

Team Setups

Custom roll forming prices are determined by looking at the setup time vs. the number of pieces you order. If it takes 6 hours to prepare the machine, setup costs are a large part of the total.

Consider this scenario. For a run of 1,000 roll formed parts for inventory, it takes one person 6 hours to set up a machine. Two people can do it in 3 hours.

In the first case, 6 hours are spread out over 1,000 parts per cost. In the second case, 3 hours of machine time is spread over 1,000 parts.

But beyond that, there’s another option. Either make the 1,000 parts (and gain 3 hours of machine run time) or make just 500 of them (equal to your 6-hr./1,000 parts cost, but you gain the 3 hours PLUS your inventory is cut in half PLUS the actual run time to make the parts is halved!).

In other words, cut the inventory in half or run the full 1,000. It all depends on your need.

Having a shorter run time does provide opportunities to do more. It might be to fit another customer’s urgent order into the 3-hour opening; or, just advance the schedule up 3 hours, creating a lead-time advantage for all scheduled Dahlstrom customers.

Maximizing Capacity With Smaller Runs

In roll forming services and all manufacturing, a direct relationship can be shown between setup time and maximizing capacity by managing run size. The option to run smaller amounts should always be on the table.

There’s a myth out there that claims the roll forming process is ill-suited for smaller runs. Dahlstrom and other roll formers actually specialize in small- and mid-sized runs, so this is simply not true. Larger, dedicated runs are nice, but we can manage mid-sized runs just as well.

Learn More About JIT Delivery in Roll Forming

The best way to see how just in time supply chain management advantages come to life is to talk to a roll form manufacturer who uses them. It’s the first step toward enjoying the benefits of consolidated costs and smooth deliveries!

To learn about how to manage your roll forming costs, use the free e-book below:

(Editor's note: This article was originally published in October 2018 and was recently updated.)

You May Also Like

These Related Stories

Beyond Costs: Roll Forming Advantages & Value

Are You Getting Roll Forming Services From An Agile Manufacturer?