Is Wood Trim Outdated? Introducing Decorative Metal Trim

Architectural wood mouldings date back to the early Greeks (like, B.C. early). From temples to homes, wood has been the backbone of most of what we build. And wood trim continues to be the most popular way to accent a room, door, or window.

Architectural metal trim is certainly not a new invention of the 21st century, either -- ever since we learned how to melt and shape metals, we’ve been using them in our architecture. One of the first recorded instances of building with decorative metal was in the third century B.C., when the 162-foot-tall Loha Maha Paya temple in Sri Lanka was topped with copper shingles.

Even today, copper and other metals remain a sign of luxury and wealth in architecture. Metal is both timeless and modern, while wood is fleeting.

So where does that leave wood?

Have interior designers exhausted all of their ideas for wood? Is wood trim outdated now?

Is Wood Trim Outdated?

Maybe wooden mouldings aren't outdated so much as they are tired and primitive (for the high-end commercial interior designer, at least).

Wood decorative mouldings are about common as a white motif. Why not do something different?

Your designs should not only be striking, they also should endure for years to come. That's not going to happen with wooden trim, even in high-traffic areas like hotels and airports. Some of the things you have to deal with:

- Splits

- Chips

- Pest infestations

- Rotting

(Related article: Should you install decorative metal trim? Or wood?)

Why Architects Love Metal

Metal offers a modern, rich aesthetic that wood simply can’t match. Even wood pieces painted to look like metal will crumble, weaken, and chip. A strong, durable metal piece can stand up to elements, human wear and tear, and other corrosive environments ... unlike wood. Wood requires extreme processing and coating to achieve the same performance.

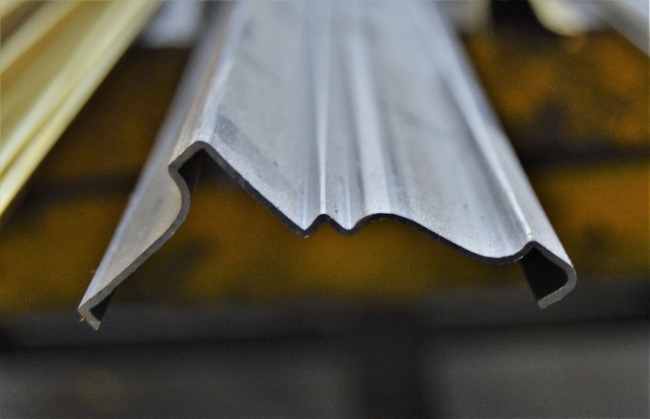

Here's what you can expect with metal trim:- Metal pieces can be either solid or perforated, sculpted or austere, without losing their strength and durability. This allows for extreme creativity and innovation in architectural design.

- Metals can be coated to retain their original color, or they can be exposed to the elements to create a gradual color-changing effect. Depending on the metal, you can achieve all sorts of finishes. Some designers even use intentional corrosion to give the metal a vintage look!

- Red metals -- copper trim, bronze trim, and brass trim -- are unmatched in their warm hues and unique aging effects. Many architects choose red metals in their designs simply for their time-worn beauty.

In short, the design flexibility, the natural rich aesthetic, and the long lifespan of metal makes architecture relevant and stunning in every century.

Uses for Metal Trim Molding

The trim molding styles you know and love in wood form are all available in metal profiles too:

- Metal chair rails

- Metal baseboards

- Metal cornices

- Metal picture rails

- Metal crown mouldings

Secondary Benefits of Decorative Metal

Aside from its unique aesthetic, metal offers a number of structural and monetary benefits.

Metals - especially red metals and coated metals - are incredibly durable and long-lived. They require fewer touch-ups than other materials (some metals require no upkeep at all), are resistant to pests and corrosion, and leave wood in the dust in terms of lifespan. Pun intended.

Metal stands up to daily abuse, doesn’t scratch, dent, or corrode easily, and is incredibly easy to clean. The beauty of decorative metal trim or panels will shine through long after a wood piece has decayed.Less upkeep means lower costs in the long-term. Similarly, metal forming processes are quite affordable - especially in large volumes. You might be surprised how much wood trim costs when you're talking oak or another high-end type. Metal is much cheaper compared to wood when produced and acquired in larger quantities.

Finally, most metals (including steels, red metals, and coated metals) are recyclable and reusable. Today, almost 70% of all steel in the U.S. is recycled. Metals offer a number of additional environmental benefits, including reducing deforestation.

Learning About Architectural Metals

Interested in how metal can impact your architectural project? Check out these two articles on Choosing Your Metal Aesthetic and the Appeal of Aged Metals.

Or, you can download the free e-book below to learn more about architectural metals and finishes:

(Editor's note: This article was originally published in January 2016 and was recently updated.)

You May Also Like

These Related Stories

Decorative Metal Trim Mouldings vs. Wood Mouldings

5 Decorative Metal Trim Ideas for Furniture & Appliances