5 Decorative Metal Trim Ideas for Furniture & Appliances

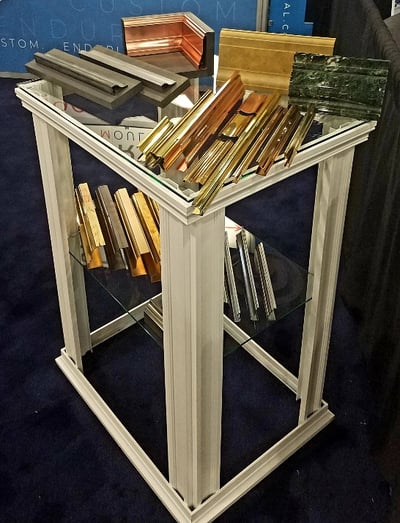

From home decor to a growing number of commercial applications, decorative metal trim is setting trends in a variety of environments. It’s a great way to create a high-end look with a relatively small amount of material.

From home decor to a growing number of commercial applications, decorative metal trim is setting trends in a variety of environments. It’s a great way to create a high-end look with a relatively small amount of material.

Metal trim is synonymous with luxury. What better way to make a first impression than by incorporating metal in areas where the visitor isn’t expecting it? Let’s go beyond traditional mouldings and look at other unique applications of decorative metal trim for furniture and high-end appliances, from display cases to furniture accents.

Decorative Metal Trim for Furniture & Appliances

Metal baseboards, cornices, chair rails, and the like are timeless ways to touch up an interior design. Now may be the time to take your designs to the next level with metal accents on:

- Display cases and shelving

- Appliances

- Cabinetry

- Hotel casegoods

- Other locations

1. Metal Trim for Commercial Display Cases & Shelving

We perceive metal trim as an indicator of class and quality. It's a great asset in any consumer goods environment that needs display cases or shelving. A nondescript product can look like a million dollars if a beautiful display surrounds it.

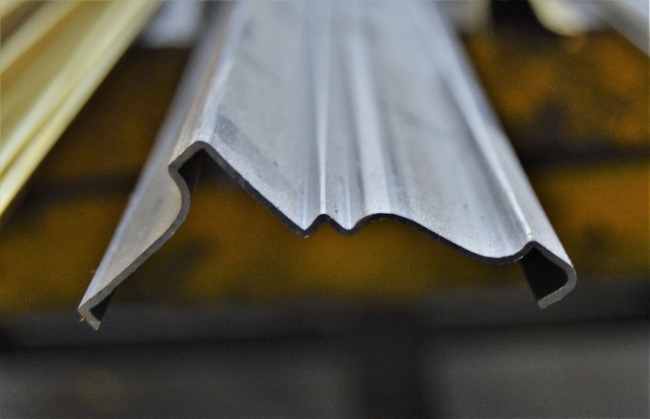

Whether it's table edges, doors or paneling, doing it with metal can increase product sales and help distinguish a product as high-end and attention-grabbing. They say that packaging is a vital marketing tool, but display can have just as significant an impact.

Every transition in plane from flat to vertical should be treated as an opportunity for embellishment.

2. Metal Appliance Trim

2. Metal Appliance Trim

Appliance design has come a long way in recent years. Aesthetics have improved on everything from dishwashers to refrigerators. (Remember the ‘70s?) Material choice has a huge role in bringing beauty to functional elements of the home.

One particularly interesting application for metal trim is oven range hoods. The metal adds a decorative element that stands on its own, but can also complement other nearby design features. Metal ranges with wooden trim usually look clunky and disjointed.

Copper and stainless steel appliance trim are two of the most popular options for custom metal ranges. Metal mouldings happen to be available in copper, stainless steel, and many other metals. You simply build it on, weld it, and make sure all the seams are nicely tucked away.

3. Metal Cabinetry Trim

From cabinets in residential homes to commercial restaurant kitchens, metal trim is an ideal accessory.

Any corner or lip can be protected/decorated with metal casing. Panel frames on flat surfaces create visual depth ... why not make them out of metal? Also, in the right circumstances, Metal panel inserts installed in the cabinetry add a nice touch.

4. Metal Hotel Casegoods Trim

(Fold-out Murphy bed design by Artone Manufacturing)

Most hotels revamp their lobbies and common areas once every 3 years due to constant wear and tear. Using more durable materials can make a big difference in maintenance and repair budgets.

Not only can metal trim wow your guests, it’s also more durable than wood and vinyl, better able to stand up to the bumps and bruises of suitcases and shoes. Just make sure that you're selecting the right material -- one that’s not easily dented or scuffed.

Decorative metal corner trim for furniture can even protect edges from damage when staff moves the furniture for cleaning or rearranging.

5. Other Ideas

There are plenty of other ways to use decorative metal trim, both in residential and commercial environments. In the home, metal can adorn:

- Rustic sinks

- Wall art

- Stair railings

- Tabletops

Expect to also see more metal trim on furniture pieces in rooms attempting to give off an industrial vibe.

In commercial environments, metal trim is a welcome addition to door frames and ceilings. Outside, it adds flash and curbside appeal to retail storefronts.

Which Metal Belongs in Your Pocket?

The options for metal trim are truly infinite. Wherever there’s a transition in plane from flat to vertical, that’s where mouldings belong.

To learn more about the best choice of architectural metal for your project, grab the free pocket guide below:

You May Also Like

These Related Stories

Decorative Metal Trim Mouldings vs. Wood Mouldings

So You're Installing Commercial Metal Trim Moulding ... Now What?