Does Copper Rust?

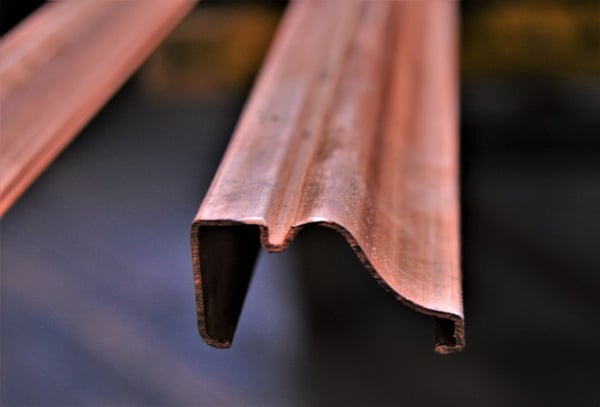

If you’re a designer cautiously looking forward to using copper in your next project, “Does copper rust?” is one question you must be asking yourself. You must also be wondering how long your copper will maintain its shiny and new look. You may also know that staying shiny, reddish-gold, and new isn’t always a must for copper.

If you’re a designer cautiously looking forward to using copper in your next project, “Does copper rust?” is one question you must be asking yourself. You must also be wondering how long your copper will maintain its shiny and new look. You may also know that staying shiny, reddish-gold, and new isn’t always a must for copper.

Either way, here are the facts about copper’s longevity and look:

Does Copper Rust? First of All … What is Rust?

To answer the question “Does copper rust?” we must first define what rusting is and how it happens. Rusting is commonly referred to as oxidation and takes place when iron or metal alloys containing iron (i.e. steel) are exposed to water and oxygen for extended periods.

Rust is an iron oxide -- an ugly reddish or yellow-brown coating that forms when iron oxidizes. It’s important to note that not all oxidation forms rust, and only iron or iron alloys can rust. Also, if controlled and preserved correctly, even iron oxide rust can look pretty cool. Other metals such as bronze and copper also undergo oxidation, leading to corrosion.

So, the answer to the question is NO, copper does not rust. However, it does corrode!

(Related: Does Brass Rust?)

What is Corrosion?

Corrosion takes place when an element that is readily susceptible to losing its electrons (like many of your favorite metals) is exposed to an element with a tendency of absorbing extra electrons (oxygen) and an electrolyte solution (water). This accelerates the transfer of electrons from the metal to oxygen.

Nasty-looking rust on iron and the beautiful blue-green color (patina) on copper after oxidation are the visible results of the metals losing electrons to the air.

Copper Oxidation

Copper and materials made of copper alloy oxidize when exposed to the atmosphere, causing its shiny surface to tarnish. You know that any water can induce corrosion, but here are factors that can make corrosion happen even more quickly:

Copper and materials made of copper alloy oxidize when exposed to the atmosphere, causing its shiny surface to tarnish. You know that any water can induce corrosion, but here are factors that can make corrosion happen even more quickly:

- Saltwater

- Heat

- Acidic compounds

After several years (depending on the environment), the tarnish gradually changes to a dark brown or black color before finally turning into a distinctive blue-green. The patina coating is what gives the Statue of Liberty its trademark appearance. And it’s why corrosion isn’t always a bad thing after all.

Copper corrodes at insignificant rates when used in areas with unpolluted air, non-oxidizing acids, and water. However, it happens more rapidly with the presence of road salt, ammonia, sulfur, oxidizing acids, etc.

Effects of Oxidation on Copper

When iron oxidizes, it produces a characteristic reddish-brown coating that doesn’t securely stick to the metal’s surface. Instead, it peels off and weakens the metal, leaving it vulnerable to further rust and decay. Copper oxidation, however, creates a decorative patina coat that not only retains aesthetic appeal, but also prevents further exposure to oxygen and curbs corrosion. And it’s why the metal is used on roofs, gutter work, and outdoor sculptures.

Copper oxidation does hinder electrical conductivity, so designers working with electricity should watch out for it.

More on Architectural Metals

If you’re curious about how other trendy and timeless metals stack up against each other, check out the Pocket Guide below. Copper is just one of many metals you can use to accent your architectural designs. Other metals that stand up strong against corrosion and rust include:

- Brass

- Bronze

- Stainless steel

Good luck!

You May Also Like

These Related Stories

Is Copper Architecture Sustainable?

Copper Welding: Interior Door Casing, Seamless Crown Moulding, & More