The Secret Trick to Great Steel Windows: Hollow, Roll Formed Parts

Steel windows are great. Steel windows on your terms are even better.

These sleek, modern products are now popular in not only commercial architecture, but in residential applications as well. It’s not hard to see why -- steel windows are the best at matching durability with elegance.

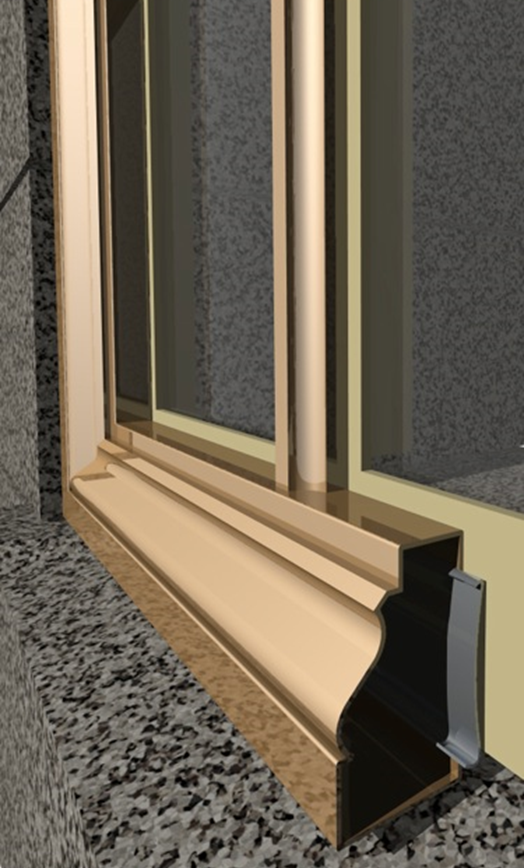

Most steel windows use solid, extruded components. But window manufacturers and designers are looking past the window itself to an easy, elegant, and inexpensive way to enhance the installation. In comes the hollow, snap-on, roll formed trim.

Steel Windows: Separating the Frame From the Trim

A steel window frame is not necessarily the same thing as steel window trim. It's all a matter of solid vs. hollow.

For starters, steel window frame extrusion process resembles that old Play-Doh machine in your mother’s attic. The metal is molten, and the manufacturer forces it through a template. It then cools and creates a solid shape -- which you'll soon learn is one of the disadvantages of steel windows.

Aluminum extrusion is very common, too, but if you really want to go high-end with a unique look, it’s all about steel window trim. (Really want to step it up? Some companies also offer extruded or machined bronze as a window construction option.)

Whittling down solid metal bars or rods into window frame components or decorative shapes can happen, but the process is very costly and produces a large percentage of scrap.

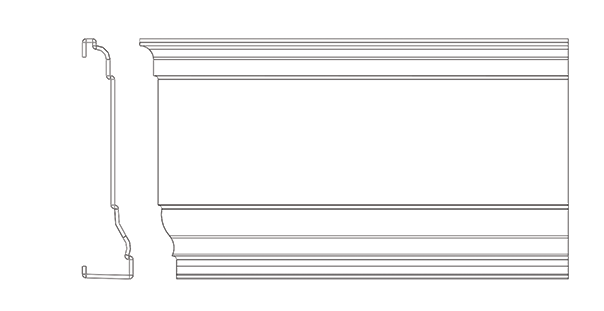

Roll forming involves the continuous bending of a long strip of coiled steel into a desired cross-section that creates a hollow roll formed part. The strip passes through sets of rolls, each set performing an incremental part of the bending.

While roll formed, hollow metal window frames are available too, solid extrusion construction is considered superior. However ... as a decorative accessory option, roll formed profiles work quite well.

With roll forming, you’re getting a similar metal look, but with a hollow piece, you can snap onto adjacent surfaces for a fraction of the cost of any solid shaping method.

Let's look further into the benefits of snap-on simplicity:

3 Advantages of Hollow Clip-on Steel Window Trim

1. You Can Still Pull Off a Vintage Look

You’ve probably noticed steel windows have a rectilinear, square look to them. A lot of today’s architects are trying to reduce the frame and increase the amount of glass present in the architecture.

If that’s your muse, great. Want a more vintage look on your steel windows? You may not be able to get it with solid, extruded parts. You instead need a hollow, snap-on part if you seek colonial-like aesthetics such as:

- Unique curves

- Unique tapers

- A more ornate appearance

This way you can dress up windows in a non-modern style but keep the style and longevity of steel. Snap-on moulding is the answer if you want similar or contrasting adjacent metal trim around windows -- whether your project is commercial or residential.

These are just a few decorative metal window trim ideas -- experiment!

2. You Can Use Current Windows

Clip-on steel parts let you work with windows already available on market with the rectilinear look you currently have.

The bonus is that you can augment your complete look with a snap-on -- whenever you want. You can add snap-on moulding to new brand-new installations or adjacent to windows that have been in place for 50 years.

3. They’re Less Expensive

Are steel windows expensive? From a construction standpoint, steel windows involve unique and high-value processes. The steel extrusion process is very expensive, complicated, and rare. If you’re considering steel windows, you’re probably in the top 1% of window buyers in terms of budget, but saving money still feels great, right?

With roll formed parts, you’ll get hollow, snap-on pieces that still carry the same great look as extruded parts, but at 25% of the cost of extruded parts. Since they’re hollow, clip-on parts require less base material to produce -- it’s like paying for Play-Doh but getting professional sculptor’s clay!

You can also adjust your material choice based on budget. The cost-conscious can go for mild steel window trim, while high-end applications may demand stainless steel window trim.

Plus, don't forget you're benefiting from the long-term cost of steel windows vs. wood. Why use metal trim for exterior windows that'll last 25 years when it could last 100s?

Steel Is the Real Deal

Hollow, clip-on metal parts are a flexible, economical option for your architecture. If you’re serious about getting a top-notch look and keeping up with trends, steel parts are even better.

So in love with decorative metal that you can’t get enough? Look into metal mouldings for your residential, commercial, or industrial building.

(Editor's note: This article was originally published in November 2017 and was recently updated.)

You May Also Like

These Related Stories

Beyond Beauty: Modern Steel Windows Qualities & Standards

5 Steel Window Designs That'll Make You Rethink Your Next Project