3 Premier Installation Materials for Exterior Metal Cladding

Are you working on a project that involves metal cladding installation? If so, you may have questions about the strength, durability, and corrosion resistance of the 'tracks' (or anchor system) into which the metal wall cladding system will fit.

We'll try to answer some of those questions below.

Choosing the Right Material For Metal Cladding Installations

Just like the cladding itself, the tracks have to stand up against the most inclement weather, including heavy winds and torrential rains. This requires a strong metal that resists corrosion. Choosing the right metal for your exterior application is crucial to the long-term success of your project. So, what are your choices?

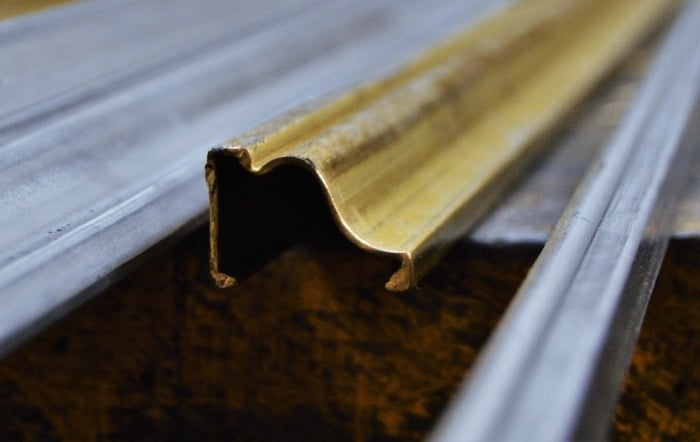

Many cladding support components are made from G90 galvanized steel because of its decent corrosion resistance relative to its price. since the facade anchors won't be seen. The strength and durability of those anchors should be your focus, and G90 fits the bill.

What exactly is G90 galvanized steel? It's carbon steel coated in liquid zinc. This coating gives it added protection against water and salt corrosion, making it ideal for external wall cladding systems.

The Benefits Of Using G90 Galvanized Steel

- It isn't as corrosion resistant as aluminum and stainless steel but it's also far less expensive!

- It offers at least 50 years of durability in dry environments and 25 or more years in saltwater or coastal environments.

- Because of preferential corrosion, the zinc layer will corrode before the steel underneath succumbs even when some of the steel is exposed.

- The more zinc that's deposited on the surface of the steel during the galvanization process, the better protection the steel will have.

As we've seen, G90 galvanized steel is affordable, durable, and perfect for exterior wall cladding anchor systems. Of course, it's not your only choice.

Stainless Steel Options

Another good choice for outdoor facade anchors is stainless steel in grades 304, 316, or 430. The most popular grade of stainless steel overall, although it's also generally the most expensive, is 304.

In a coastal environment, 316 stainless steel is the most corrosion-resistant metal available that is also cost-effective in large applications like cladding. The least expensive option is 430. However, it lacks the corrosion resistance of the other two.

Stainless steel nicely balances durability and cost-effectiveness in all outdoor applications.

Anchoring With Aluminum

Aluminum is a cost-effective choice for external wall cladding systems (both surface panels and anchoring systems). It's a lightweight metal, which makes it ideal for applications where lower weight is appealing. Since the framing is exposed in the infill system of facade anchoring, either stainless steel or aluminum are more aesthetically pleasing choices than galvanized steel.

Shapes & Systems For Facade Anchors

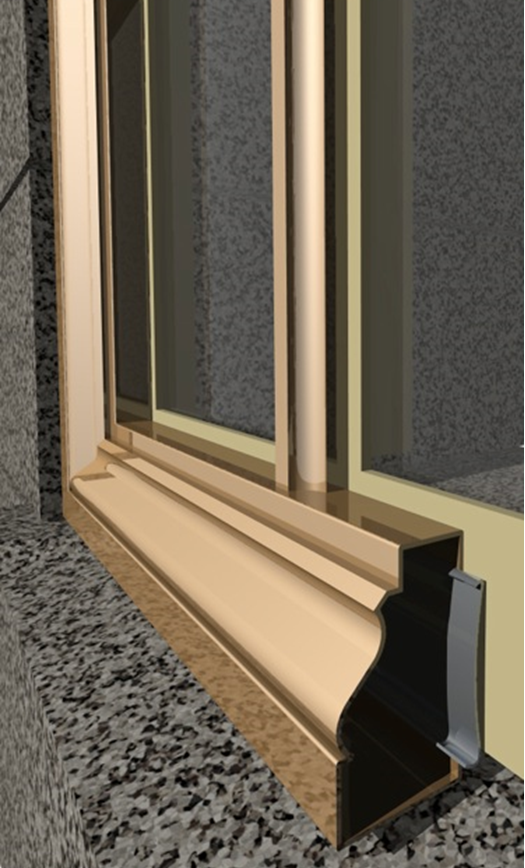

The cladding installation system you choose should be based on the type of cladding you're installing. That said, there are three main types of cladding installation systems.

- The attached system involves attaching large cladding panels directly onto the building's structural frame. This method requires a very carefully thought-out design but may save time during installation. The panels are attached to the slab edges with anchors.

- The curtain wall is an efficient system using panels that are fixed onto a lightweight frame during the manufacturing process. Clip angles are used to attach the panels to the structural frame and related components.

- With the infill system, the structural frame is left exposed after installation. Since the cladding panels can be installed from inside the building with this system, it reduces any scaffolding risks.

The Finishing Touches

Although galvanized steel has built-in protection from its zinc coating, you may want to consider painting or powder coating it or other metals before using them in a wall cladding anchor application.

The more protection from the elements they have before the metal cladding installation, the longer they'll last before maintenance is required. This is particularly important with commercial wall cladding systems because of the potential disruption involved in the maintenance process.

Deciding on the best metal for an exterior project isn't easy! It requires plenty of research and thought on your part. Getting the metal manufacturer involved can definitely help with your decision-making process. After all, who knows the capabilities and potential drawbacks of the product better?

A thoughtful, well-informed decision will have a long-lasting impact on the success of your exterior cladding project.

Are you interested in obtaining more information about facade anchors, including brick veneer and stone cladding anchor systems? Check out our free e-book on design guidelines for roll formed components:

You May Also Like

These Related Stories

So You're Installing Commercial Metal Trim Moulding ... Now What?

The Very Most Corrosion-Resistant Metals