The OEM Guide to High-Performance Server Rack Manufacturing

As modern data centers evolve to support GPU-heavy technology and high-density storage, OEMs are being forced to rethink …

Why Roll Forming Is the Best Fit for Warehouse Shelving Components

Warehouse shelving systems live or die by one thing: repeatability. When your vertical posts don’t align, holes don’t ma …

9 Design Tips for Ground-Mounted Solar Structures

Ground-mounted solar installations differ from rooftop systems in significant ways. Without building geometry constraint …

Data Center Support Infrastructure: Raised-Floor vs. Overhead Systems

Behind every terabyte processed and workload deployed is a framework of precision-engineered steel. One of the most impo …

Data Center HVAC Design: Don't Neglect the Infrastructure

Why HVAC Design Makes or Breaks Data Center Performance Data centers power the digital services we rely on every day, fr …

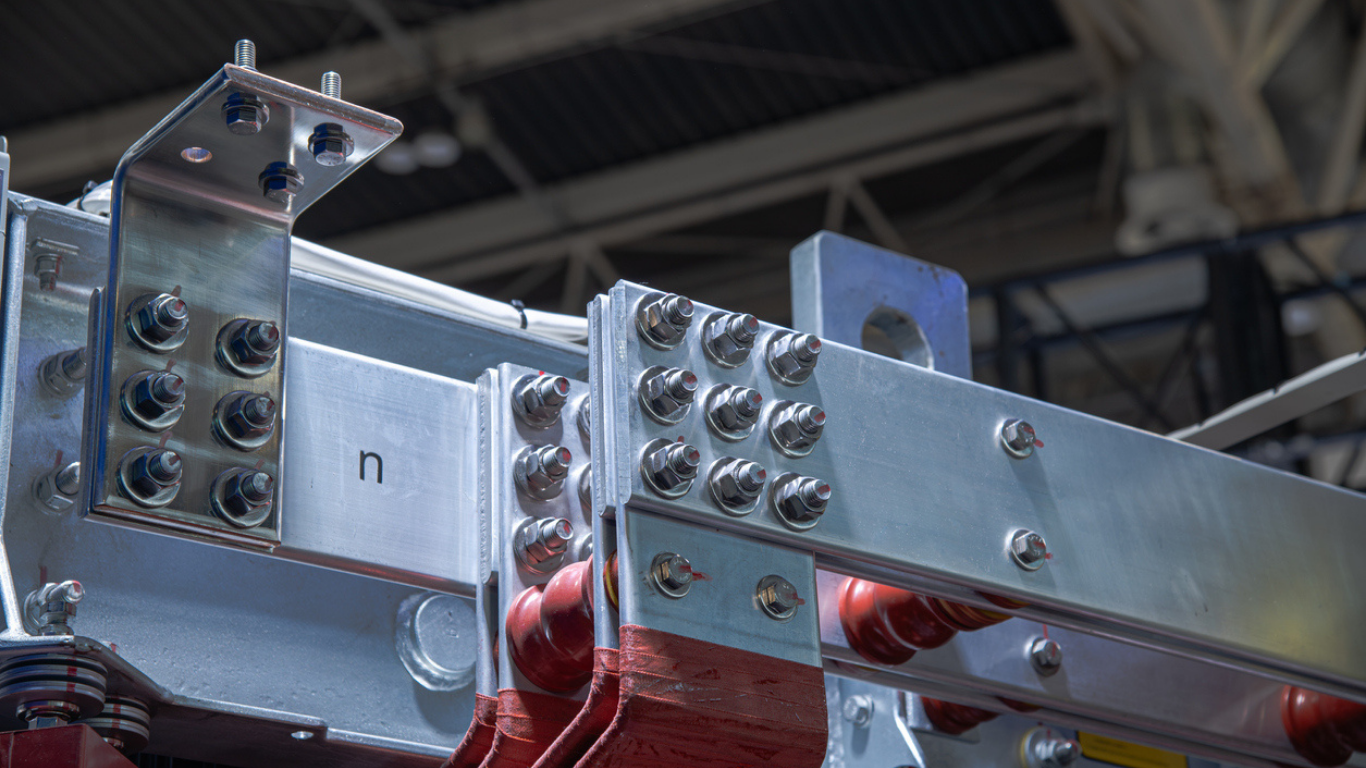

Data Center Power Distribution Brackets & Busway Framing For High-Amp Power

Your data center just went dark. It wasn’t a utility grid failure; it was an overheated connection that failed under the …

Retrofit Guide: Strengthening Server Racks with Stiffeners and Beams

Are Your Legacy Racks Keeping Up? Legacy server racks were never designed to handle the weight of today’s equipment. GPU …

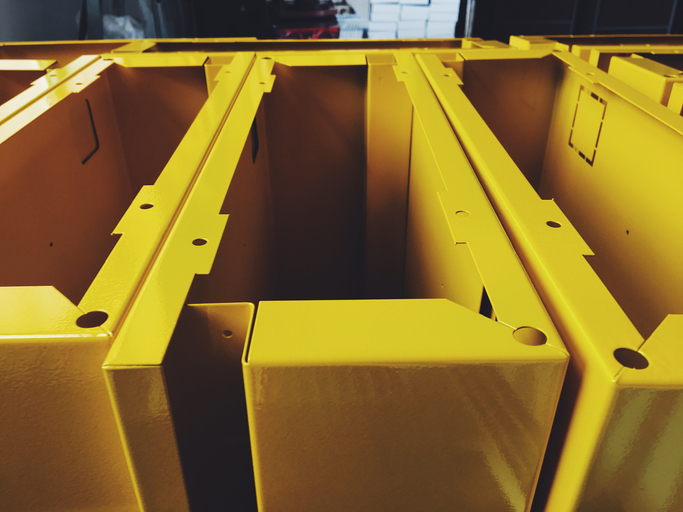

Industrial Powder Coating vs. Paint for Roll Formed Parts

You’re working with a roll former. You’ve specced out your parts – you’ve accounted for your bend radii, tolerances, and …

Goodbye Gray: Powder Coated Steel Roll Formed Parts

Most people wouldn’t name gray as their favorite color. In most instances, the hue carries with it a drab connotation.

Can You Powder Coat Aluminum? And Other Powder Coating FAQs

For many metal parts finishing projects, powder coating is a great option.