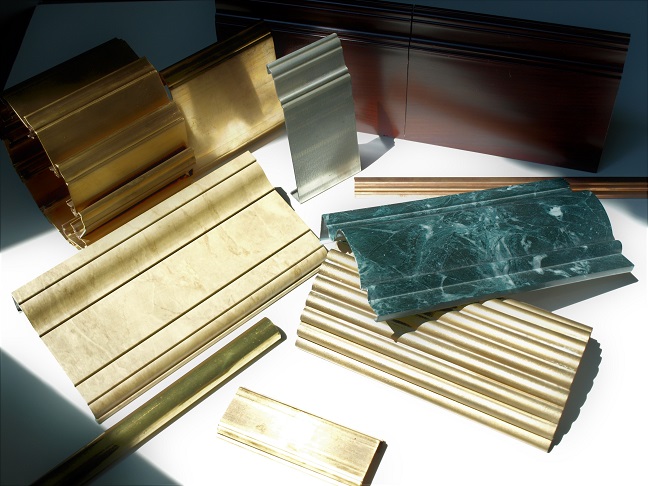

A Metal Moulding Installation Guide for Wary Contractors & Designers

The partnership between architect/designer and installer/contractor is often one of compromise, and stress. When it come …

Can Copper Antimicrobial Products Make Hospitality Design Safer?

The coronavirus pandemic has forever changed the way many of us think about architectural design and materials.

Copper Welding: Interior Door Casing, Seamless Crown Moulding, & More

(Photo courtesy Miller Welds) Can you weld copper? Absolutely. The trick is establishing the ideal joining method for yo …

DYK? Dahlstrom Architectural Mouldings & Doors Grace These 5 Landmarks

The biggest, boldest architectural projects in America demand unique solutions for both form and function. Dahlstrom Arc …

What Goes Into Roll Formed C & U Channel Prices?

To manufacturers, a channel is one of the most simplistic shapes on earth. This helps explain why channels are a commodi …

Architectural Wire Mesh & Perforated Metal Panels: 3 Benefits, 10 Uses

Architectural design aims to balance economy, elegance, and efficiency. Perforated metal paneling and wire mesh certainl …

Inside Peek at Steel Door Frame Component Manufacturing

Metal manufacturing is fascinating because it’s always getting better. Take steel doors and frames -- today’s manufactur …

How to Cope a Moulding? Easy -- Try Seamless Baseboards & More

Architects are often frustrated when they see a finished installation of trim mouldings that have unsightly gaps. But wh …

Commercial Interior Design Ideas: Decorative Metal Trim for Furniture

Decorative metal trim for furniture isn’t new. In fact, it's many centuries old. It had a long existence as a symbol of …

Galvanized Steel Vs. Stainless Steel in Architecture & Interior Design

Galvanized steel and stainless steel are big in construction circles -- but what about architecture and interior design? …