Sustainable Architectural Materials: Does Bronze Count?

Sustainable architecture is increasingly becoming the norm due to pressure both from regulators, the general public, and …

Metal Mouldings: Care and Maintenance

(Photo courtesy Jack Gruszka of Full Spectrum Interiors Corp. -- Mountain Ridge Country Club in West Caldwell, N.J.) Whe …

3 Benefits of Steel Doors in Industrial & Commercial Use

Every year, more building owners choose to install and use steel doors instead of traditional wooden doors, but why is t …

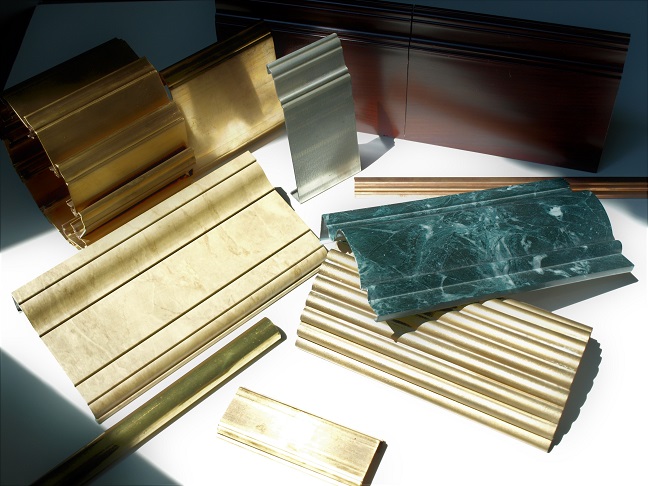

5 Decorative Metal Trim Ideas for Furniture & Appliances

From home decor to a growing number of commercial applications, decorative metal trim is setting trends in a variety of …

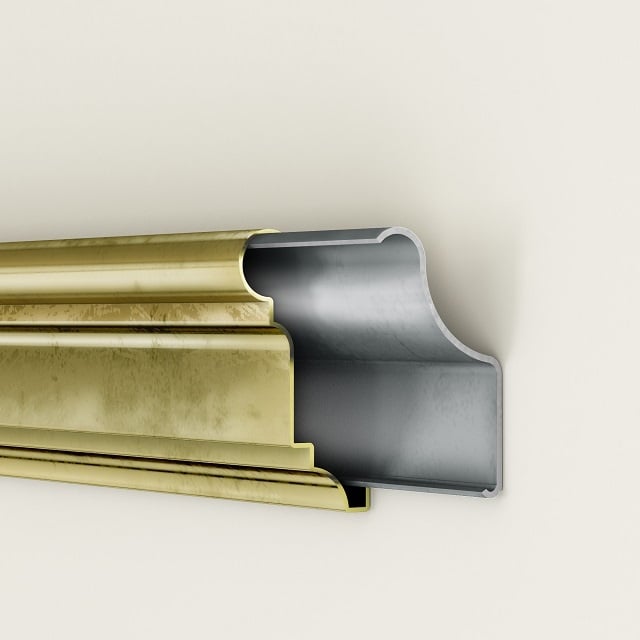

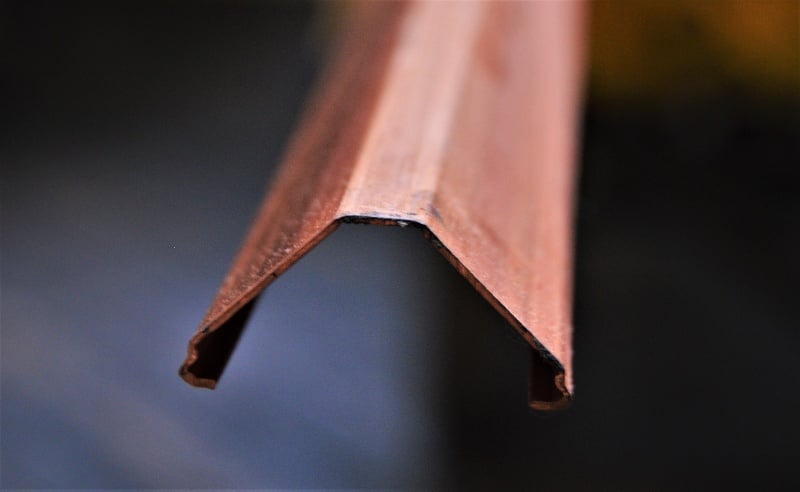

Metal Picture Rail Mouldings: Add Class to a Gallery, Museum, or Home

Picture rails are the least familiar of all metal mouldings. But that only means more opportunity for you, right? Shunni …

5 Uses for Metal Picture Rail Mouldings to Kick-Start Your Creativity

DIYers on Pinterest and other websites have been devising fun ways to use picture rails in interior design for years. Bu …

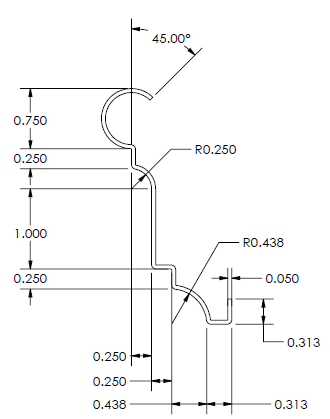

So You're Installing Commercial Metal Trim Moulding ... Now What?

Most contractors have seen and done it all. But when it comes to installing trim moulding, many of them have limited exp …

Mixing Materials in Architectural Design

Mixing materials in architectural design isn't a new concept. In fact, architects have been designing schools, museums, …

Benefits of Non-Ferrous Metals in Architectural Design

Non-ferrous metals are what brought us out of the Stone Age and into the Copper and Bronze Ages. From 4500 B.C. to 1500 …

A Metal Moulding Installation Guide for Wary Contractors & Designers

The partnership between architect/designer and installer/contractor is often one of compromise, and stress. When it come …