Mixing Materials in Architectural Design

Mixing materials in architectural design isn't a new concept. In fact, architects have been designing schools, museums, cathedrals, and nearly every other building using a mix of materials for centuries.

Combining different materials in architecture will end up playing a major role in the durability and aesthetics of the building you're designing.

Why should materials be mixed?

The best architects aren't afraid to combine dissimilar materials in their pursuit of artistic expression. Instead, they understand that just as a chef needs to combine ingredients to create a delicious, memorable meal, they also have to bring together different architectural elements to create a work of art that's beautiful, durable, and memorable.

Mixed Materials in Architecture Create a Visual Contrast

Like artwork, mixing materials can break up large expanses of similar, otherwise-boring designs.

Using different ratios of dissimilar materials can create a spectrum of ambiance. Incorporating more metal, for example, will create a cool, industrial aesthetic, while incorporating more wood will create a warmer, more organic look and feel.

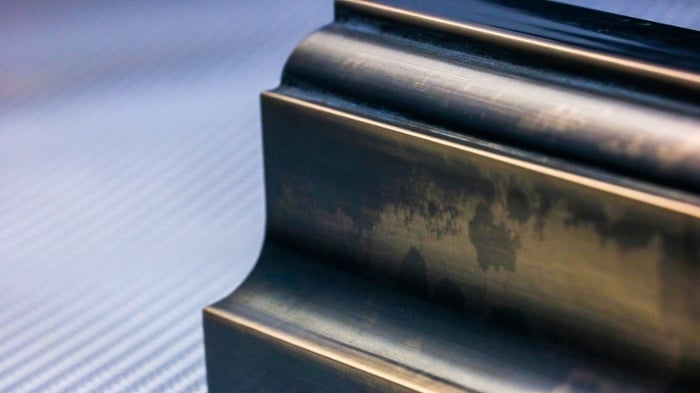

Metal, wood, glass, and stone can also be layered to accentuate dimensions and create further contrast. Placing dissimilar materials on top of each other creates a striking visual distinction, and the transitions between different materials can be further accentuated by decorative trim, such as wood or metal mouldings.

These layers of contrast can elevate a design from flat and boring, to powerful and thought-provoking.

Contemporary design is all about contrast -- we want our art and architecture to have character, multiple dimensions, and a surface-level simplicity that gets more and more complex upon further inspection.

Mixing metal with wood, stone, or brick brings those colors and textures together to create a unique, visually appealing work of architectural art.

Practical Architectural Benefits of Mixed Materials

Without mixing materials, you'll ultimately limit your design's functionality. Some materials are more durable, making them ideal for high-stress or corrosive environments; other materials are more delicate, but can still add just as much value to your design.

Metal (or even metal cladding) keeps your architecture standing strong longer. Stainless steel, galvanized steel, and red metals are incredibly corrosion-resistant; and can easily last decades.

Mixing materials can also decrease the overall cost of your project. Using lower-cost metals such as stainless steel will help offset the costs of special additions, such as sequoia wood accents.

Design can be optimized for quality of life by strategically using highly insulating materials. For instance, wood may be a better material for outside-facing walls since it's a better insulator, while metals may work better for inner walls. A combination such as metal-clad wood can also be used to provide both insulation functionality and visual appeal while keeping insulating costs down.

Mixing Materials in Architecture is an Art

Finding or creating the right combination of materials to use is as much a form of art as it is a science.

An architectural designer should be focused on determining the optimal materials to use for a given project while simultaneously creating a unique, lasting work of art. To accomplish this, they must understand both the practical benefits of the different materials available as well as how to use the materials in a visually appealing way.

(Editor's note: This article was originally published in October 2016 and was recently updated.)

You May Also Like

These Related Stories

Which Profiles & Metals Make the Best Picture Rails?

Metal Mouldings 101: The Dahlstrom Bedrock