Roll Formed parts: 5 Expert Tips for Designing the Worst Parts Ever

Who wants to make great roll formed parts? Not you, obviously.

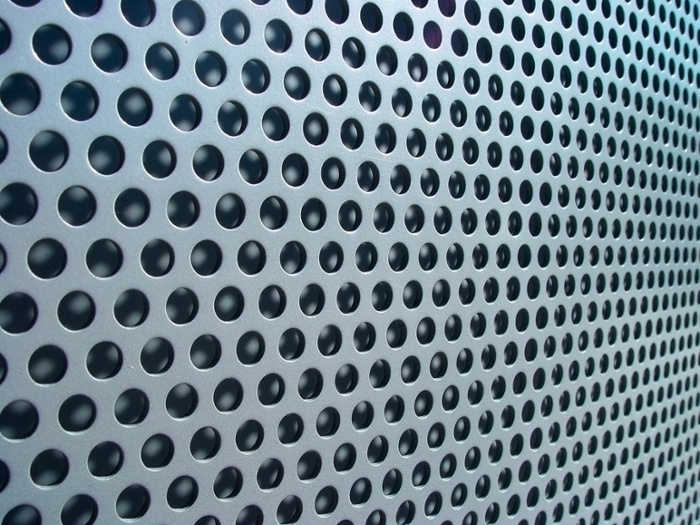

Roll Forming: A Versatile Sheet Metal Punching Partner

Roll formed components often require hole punching -- after all, that’s probably one reason why you chose roll forming t …

3 Premier Installation Materials for Exterior Metal Cladding

Are you working on a project that involves metal cladding installation? If so, you may have questions about the strength …

5 Corrosion-Resistant Building Materials | Architectural Metal Design

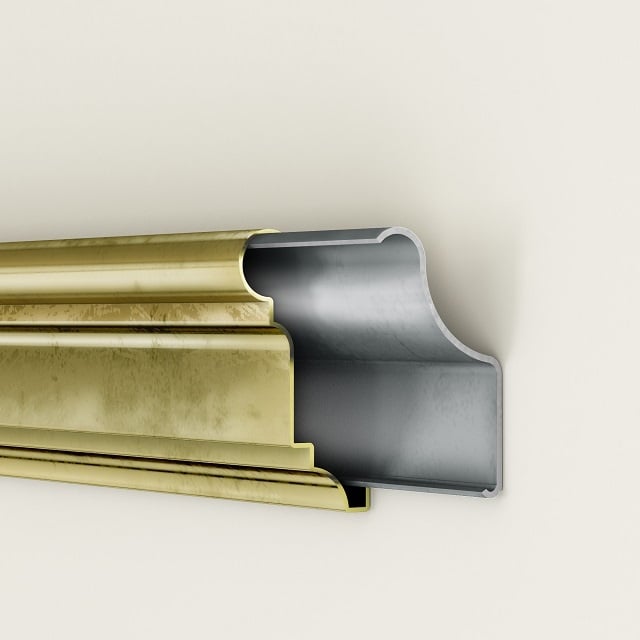

Decorative metal mouldings were a staple of early 20th-century design. They adorn some of the world’s most recognized bu …

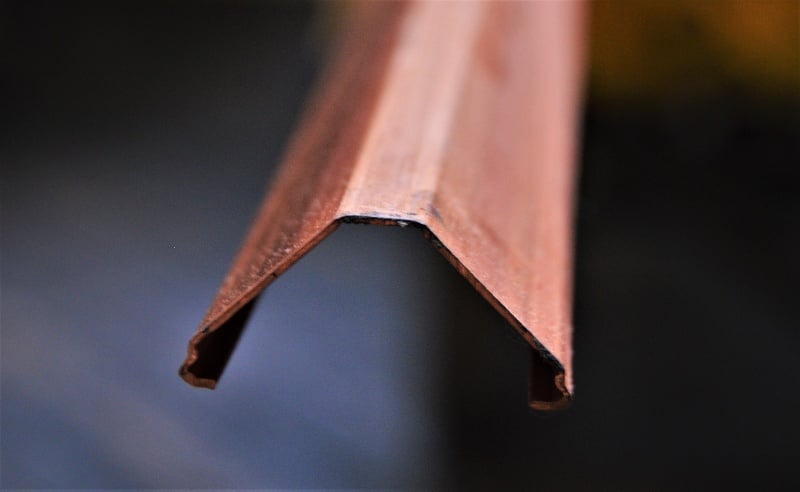

Architectural Building Materials: Does Brass Rust?

Brass is one of the great luxury metals, alongside copper and bronze. It’s considered to be an architectural building ma …

Metal Door Casing Ideas for Interior & Exterior Designers

The standard metal door frame is … nothing to get excited about. While it does offer structural and durability benefits, …

List of Sustainable Architectural Materials | Exterior/Interior Design

For those working in architecture and interior design, the concept of sustainability is often of paramount importance. N …

Sustainable Architectural Materials: Does Bronze Count?

Sustainable architecture is increasingly becoming the norm due to pressure both from regulators, the general public, and …

Metal Mouldings: Care and Maintenance

(Photo courtesy Jack Gruszka of Full Spectrum Interiors Corp. -- Mountain Ridge Country Club in West Caldwell, N.J.) Whe …

3 Benefits of Steel Doors in Industrial & Commercial Use

Every year, more building owners choose to install and use steel doors instead of traditional wooden doors, but why is t …