Why Get Custom Roll Forming From a Single Source?

For manufacturers who require a continuous flow of custom roll forming, late shipments and stock outages can negatively …

Reshoring Your Roll Forming To Create a More Efficient Supply Chain

You’ve seen the pictures of shipping barges idling off the coasts of the United States. You may have had delays in shipm …

Beyond Costs: Roll Forming Advantages & Value

You need a metal forming process that will produce a quality product at the right price, meet your inventory needs, and …

Why Your Roll Former Needs Better Manufacturing Shipping Solutions

Customers don't ask for much. All they want is the right product at the right price, delivered on time and free from def …

How Solar Panel Frame Manufacturers Can Fix a Roll Form Supply Chain

The cost of completing a solar installation project continues to drop. Part of the reason is that component manufacturin …

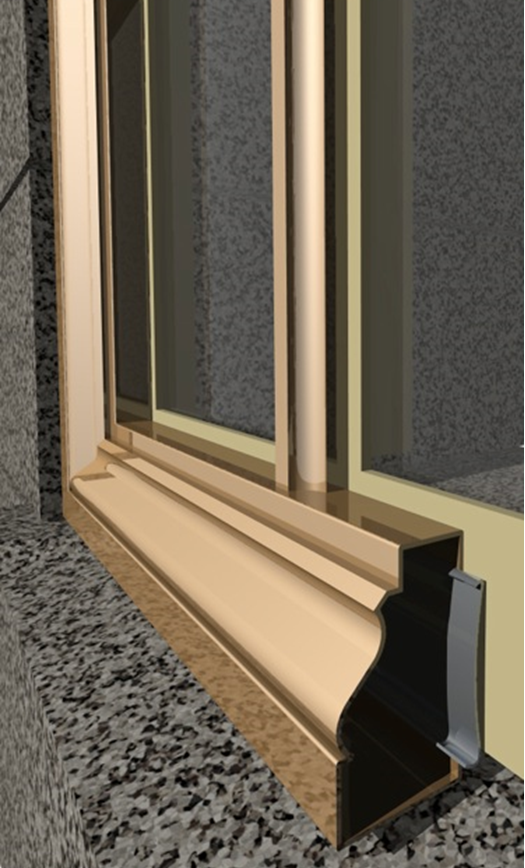

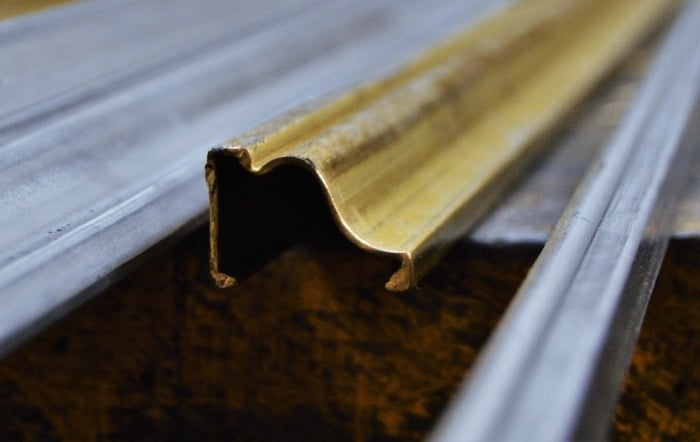

The Secret Trick to Great Steel Windows: Hollow, Roll Formed Parts

Steel windows are great. Steel windows on your terms are even better. These sleek, modern products are now popular in no …

5 Steel Window Designs That'll Make You Rethink Your Next Project

Steel windows boast a sleek, modern look. They've been used by architects for generations in numerous residential and co …

Choosing Your Aesthetic for Architectural Metal Mouldings

Choosing the right aesthetic for your architectural project is more complex than it may seem. There are many metals to c …

Traits a Metal Fabrication Partner Needs to Make Your Design a Success

Metal is in style. Each metal creates a different aesthetic, meshes well with other materials, and is highly functional …

The Very Most Corrosion-Resistant Metals

For most projects, no single factor drives the choice of metal for any kind of application. You might want something tha …