201: The Hero You Deserve for Stainless Steel Outside Use

Have you ever heard about 201 stainless steel? It’s a surprisingly nice metal for outdoor projects that demand a blend of power, finesse, and beauty.

Part of the 00 series of stainless steels, this metal is known for its use in indoor products like restaurant equipment, appliances, and cooking utensils. But 201 stainless will amaze you with its suitability for outdoor parts, including:

- Automotive trim

- Architectural applications

- Grills and other outdoor appliances

- And more!

201 Stainless Steel Outside: The Specs

201 stainless steel specifications can be broken down into four main categories:

- Cost

- Toughness

- Resistance

- Formability

Cost

This grade of stainless steel’s relatively low cost is resulting in more frequent use among engineers and architects. Because it’s light in weight, you can pack in more per pound.

Toughness

In certain applications (more on these in a sec), you need an extremely hard metal.

You’ll get great impact resistance with 201 stainless steel. Its toughness in cold conditions is excellent, too. This grade offers about 30% better yield strength than, say, 301 stainless steel (another popular choice) while keeping equal ductility -- allowing designers to reduce heaviness. This is what makes 201 stainless so valuable in certain applications.

Resistance

These projects also require high corrosion resistance, another plus for the 201 grade. However, it’s less resistant than its 301 counterpart, particularly in environments with chemicals present. The 201 grade is part of a series known for low nickel content, which, long story short, is why 201 is less resilient than 301. Don’t fuss -- it still easily beats other metals (carbon steel, aluminum, etc.) in corrosion resistance.

Formability

On the downside, 201 stainless has high springback, meaning it will bend back toward its original shape a bit. Your manufacturer will have to overbend your part to compensate.

Where 201 Stainless Steel Reigns Supreme

The bad news first: 201 stainless steel is not ideal for structural outdoor applications because it’s prone to pitting and crevice corrosion. The low nickel content narrows the range of capabilities for the 201 grade, unfortunately.

However, there are a few areas where you will find that 201 stainless steel is a go-to metal choice:

- Automotive

- Architectural

- On the road

1. Automotive

Folks like their rides to be nice and shiny while remaining strong. It’s no wonder 201 continues to gain traction as an option for automotive trim.

Train car exterior components -- like the siding or the base sill along the lower edge of a car -- are often made of 201 stainless steel. The transit cars you see in New York City may very well be covered in this grade. In some of these cases, engineers use an ultra-hard alloy of 201 for optimal impact resistance.

Remember, the outstanding combination of lightness, toughness, and aesthetics is what makes stainless shine in the transportation industry.

2. Architectural

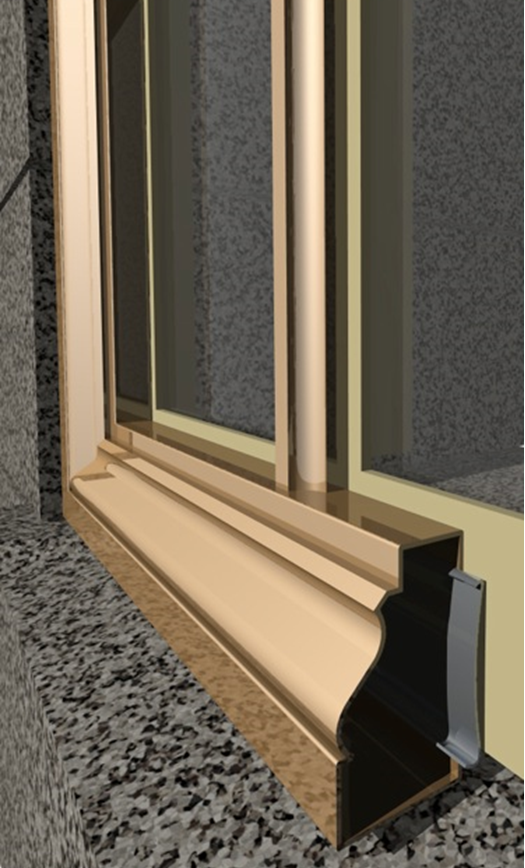

Typical architectural uses include:

- Doors

- Windows

- Railway cars

- Trailers

- Hose clamps

Architects can involve 201 stainless when using metal for surface cladding. Sometimes high rises are covered in modular panels that are all connected to the building with concealed 201 stainless roll formed parts.

What about outdoor escalators where exposure is an issue? 201 stainless can be great for the framing of the stairs. The rollers for the steps ride on roll formed parts, too (though they’re inside the escalator).

Will your project will be near water? 201 stainless can handle that, too. Still, there may be better metal options for coastal applications.

3. On the Road

Government infrastructure projects often call on 201 stainless steel. Examples include:

- Guardrails on highways

- Highway signs

- Other general signage

This steel grade is a great option for the trim that frames an outdoor sign -- especially if your order is large. These projects typically require U channels, hat channels, Z angles, and regular angles.

Got a Project You Need Help With?

The 201 grade of stainless steel is specialized for heavy-duty cases. Not sure if you need to spring for 201? Talk to a trusted manufacturer about the details of your design.

Remember, projects that need 201 stainless are ones that must blend:

- Power

- Finesse

- Beauty

If you'd like to learn more about architectural metals, download our free pocket guide below:

(Editor's note: This blog post was originally published in October 2017, and was recently updated.)

You May Also Like

These Related Stories

Galvanized Steel Vs. Stainless Steel in Architecture & Interior Design

What Is Duplex Stainless Steel, and Can It Be Roll Formed?