High-Quality Heat Pump Parts: Try Metal Roll Forming

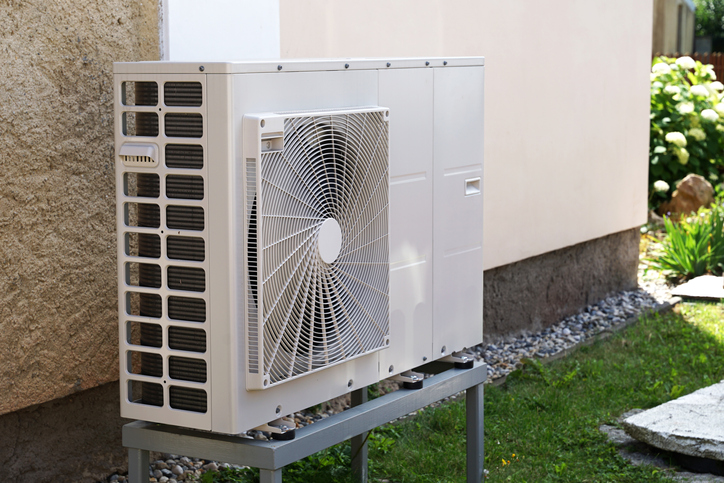

The HVAC industry is witnessing a surge in heat pump popularity. Sales of heat pumps are outstripping gas furnaces for h …

Sheet Metal Roll Forming: Assessing Cost, Ability, & Quality

Sheet metal roll forming is one of the most affordable metal fabrication processes. The ability to manufacture large qua …

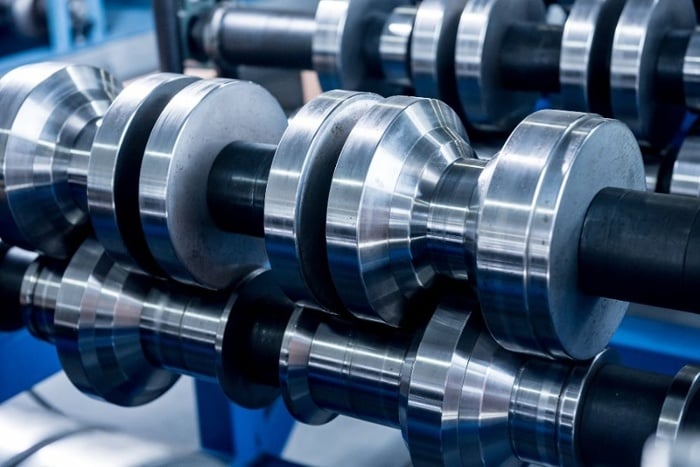

What Is Metal Roll Forming? | Metal Manufacturing Processes

“What is metal roll forming?” Even design engineers with 20+ years of experience still Google this question. Despite its …

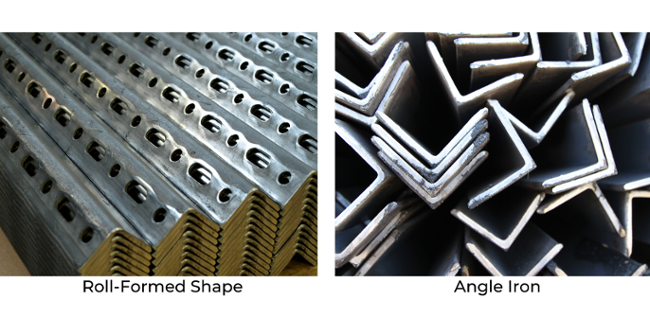

Need a metallic L-angle? Roll Forming vs. Angle Iron

You need long, slender, L-shaped metal components for your project. Several metal forming processes can achieve the desi …

Beyond Steel: Mastering Metal Properties for Your Roll Forming Project

A deep understanding of metal properties is your secret weapon in roll forming. It gives you the confidence to make the …

6 Important Factors in Manufacturing a Solar Racking System

Solar energy is thriving in the United States, fueled by an impressive 24% average annual growth rate over the past deca …

Custom Roll Forming Processes: Cold Roll Forming Steel

Metal fabrication can be complex, but there are certain methods that can be used to make it simpler and more efficient.

Roll Forming Services: Your OEM & Architectural Solution

You’re looking for custom metal forming services, and you come across roll forming – but there’s two kinds: OEM and arch …

Warehouse Storage Racks and Conveyors: Consider Roll Forming

Global shifts are sharply impacting the way companies in the United States do business. Carrying on the trend toward exp …