The Benefits of Using a Full-Service Roll Forming Company

Full-service roll forming companies should give you expert advice, help you design quality parts, and find ways to keep …

A Metal Roll Forming Partner Mustn't Be Big to Boost Your Business

Are you searching for a manufacturing partner capable of producing large quantities of products? Who is both efficient a …

Roll Forming Advantages: Efficiency & Cost-Savings

Since the turn of the 20th century -- or perhaps much earlier -- roll forming has been used to quickly and cost-effectiv …

The Hidden Expense: Roll Forming Raw Material Cost

OEM projects can be hectic. Your main concerns are likely lead time, reliability, quality, customer satisfaction, and co …

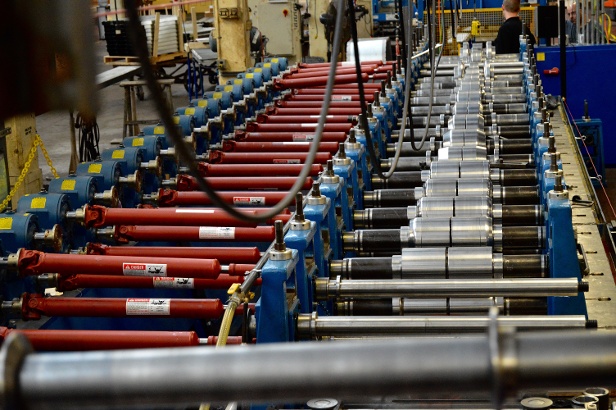

3 Considerations: Partner With A Roll Former Corporation Vs. In-House

Bringing metal roll forming processes into your plant is a complex investment. It’s more than just buying a machine that …

Warehouse Storage Racks and Conveyors: Consider Roll Forming

Global shifts are sharply impacting the way companies in the United States do business. Carrying on the trend toward exp …

Communication Is Key To Supply Chain Risk Mitigation

When you think about supply chain risk mitigation, what are the first things that come to mind? For us, the usual suspec …

How Vendor Managed Inventory Benefits Your Bottom Line

Maintaining an inventory of what a client needs for production is a delicate and complicated balance. As inventory ages, …

JIT Delivery: 1 Step a Roll Forming Manufacturer Must Take

There’s nothing new or mysterious about “just-in-time” or JIT manufacturing. The idea has been around since the 1970s, a …

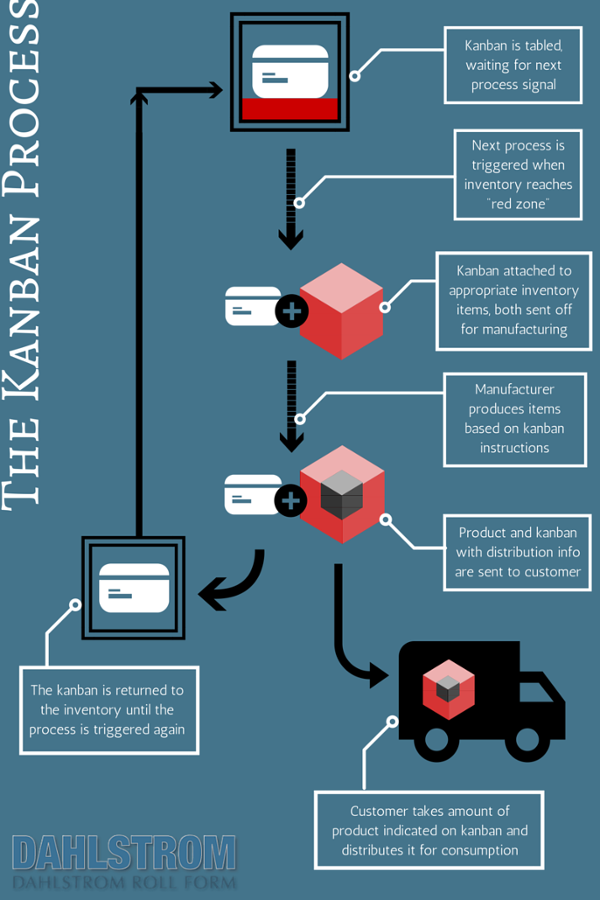

Keep Roll Forming Costs Under Control With Kanban Inventory Management

Keeping control of inventory requires intentionality. Insufficient inventory management leads to more waste, higher cost …