The Hidden Expense: Roll Forming Raw Material Cost

OEM projects can be hectic. Your main concerns are likely lead time, reliability, quality, customer satisfaction, and co …

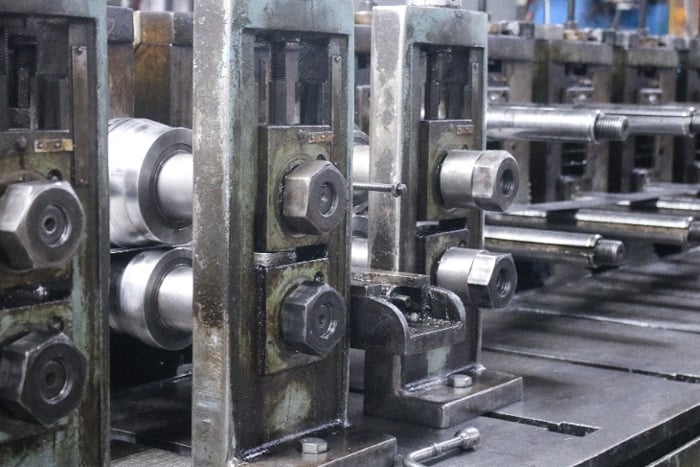

Choosing the Right Path: Roll Forming vs. Other Metal Parts Manufacturing Processes

As manufacturers, we all know that the magic behind a top-notch product lies in a solid manufacturing process, but with …

A Legacy Continued: Local Experienced Leaders Take Over Ownership

Carrying on the 120-year history of local ownership in Western New York state, the current owner of Dahlstrom Roll Form …

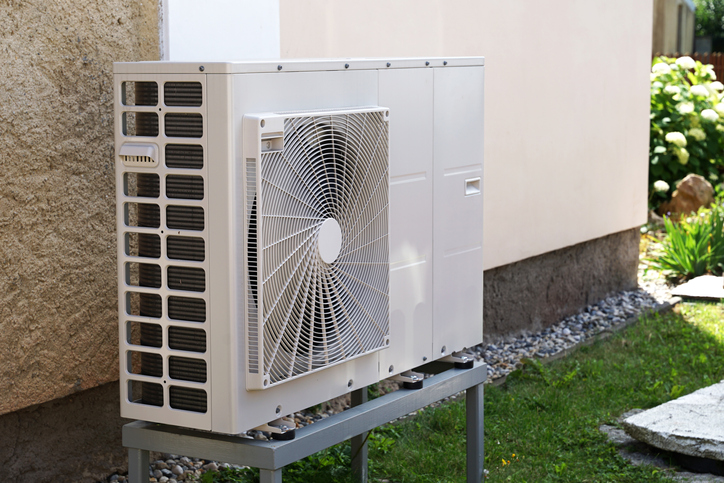

Commercial HVAC-R Parts: Is Roll Forming a Fit?

The commercial HVAC-R (heating, ventilation, cooling, and refrigeration) industry is rapidly growing. Experts predict th …

High-Quality Heat Pump Parts: Try Metal Roll Forming

The HVAC industry is witnessing a surge in heat pump popularity. Sales of heat pumps are outstripping gas furnaces for h …

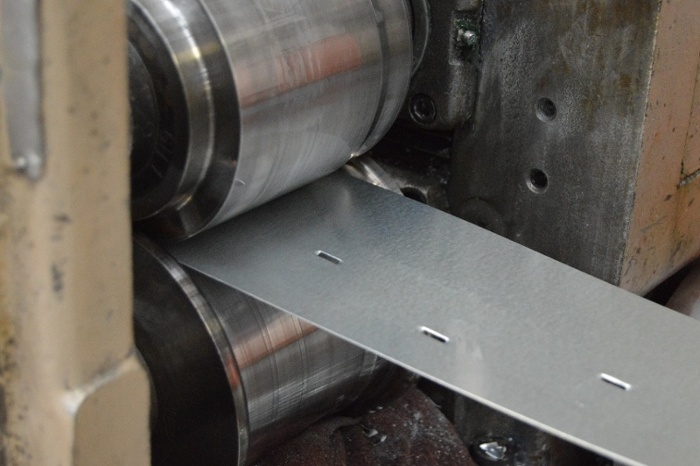

4 Steps to Controlling Roll Forming Costs

Control your roll forming costs without sacrificing parts’ quality with these four steps to efficiency: Roll former spee …

Sheet Metal Roll Forming: Assessing Cost, Ability, & Quality

Sheet metal roll forming is one of the most affordable metal fabrication processes. The ability to manufacture large qua …

A Roll Forming Design Guide for Enclosed Trailer Parts

In the competitive world of trucking, every pound counts. Creating commercial trailer parts requires balancing innovatio …

Harnessing Metal Roll Forming for Indoor Vertical Farming Systems

The landscape of agriculture is transforming, driven by a growing demand for sustainable, local, and year-round access t …