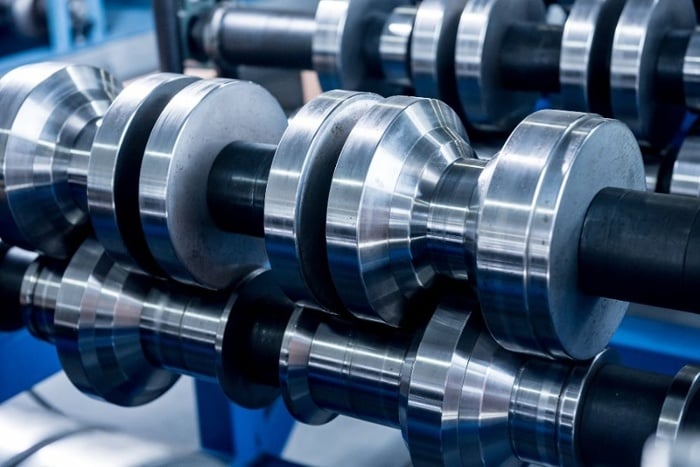

Custom Roll Forming Processes: Cold Roll Forming Steel

Metal fabrication can be complex, but there are certain methods that can be used to make it simpler and more efficient.

Career Advancement: See Yourself Growing at Dahlstrom

Are you always seeking to improve yourself and learn new things?

3 Considerations: Partner With A Roll Former Corporation Vs. In-House

Bringing metal roll forming processes into your plant is a complex investment. It’s more than just buying a machine that …

Roll Forming Services: Your OEM & Architectural Solution

You’re looking for custom metal forming services, and you come across roll forming – but there’s two kinds: OEM and arch …

Roll Forming Tooling Design: Build In-House or Outsource?

Which charges higher prices for metal fabrication -- a company that has in-house roll forming tooling design capabilitie …

Warehouse Storage Racks and Conveyors: Consider Roll Forming

Global shifts are sharply impacting the way companies in the United States do business. Carrying on the trend toward exp …

5 Definitions of Durability in Engineering for Roll Forming

In roll forming, there are five ways to define durability in engineering. To get the component you want, make sure to un …

The 4 Most Common Myths of Roll Forming Metal

There are a lot of common misconceptions about roll forming metal. Four of the most common myths about the roll forming …

Communication Is Key To Supply Chain Risk Mitigation

When you think about supply chain risk mitigation, what are the first things that come to mind? For us, the usual suspec …

How Vendor Managed Inventory Benefits Your Bottom Line

Maintaining an inventory of what a client needs for production is a delicate and complicated balance. As inventory ages, …