Power Distribution System Components: Roll Forming Benefits

The U.S. power distribution sector is under a storm cloud.

Industrial Paints & Coatings: Types of Metal Finishes

Metal finishes are a critical component of many industrial applications, serving to protect your industrial parts’ surfa …

Data Center Rack Design & Infrastructure: Is Roll Forming a Fit?

Data centers are the backbone of today’s digital world.

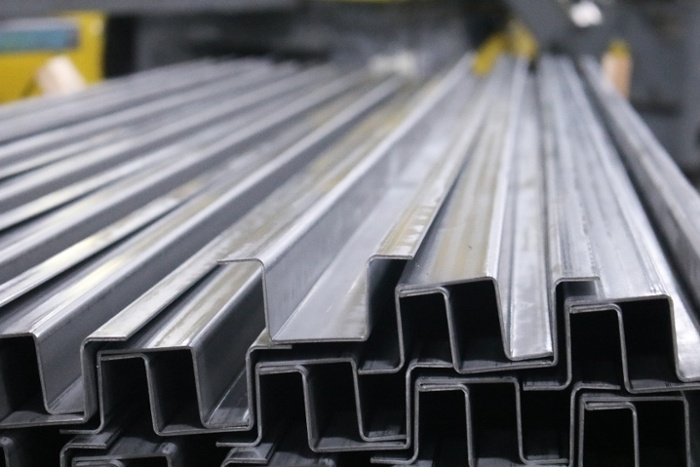

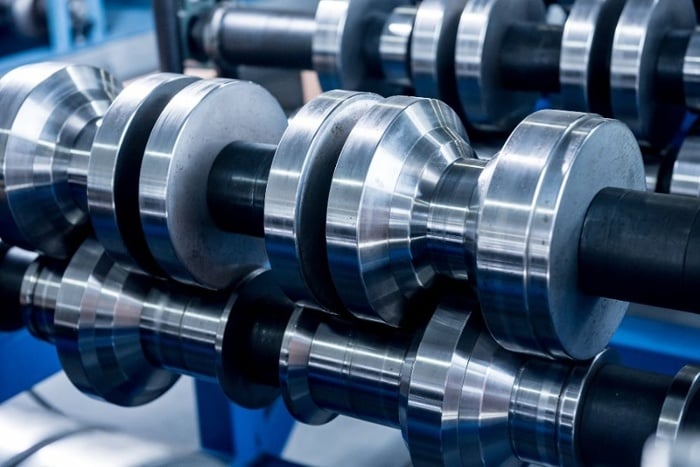

Custom Roll Forming Processes: Cold Roll Forming Steel

Metal fabrication can be complex, but there are certain methods that can be used to make it simpler and more efficient.

Career Advancement: See Yourself Growing at Dahlstrom

Are you always seeking to improve yourself and learn new things?

3 Considerations: Partner With A Roll Former Corporation Vs. In-House

Bringing metal roll forming processes into your plant is a complex investment. It’s more than just buying a machine that …

Roll Forming Services: Your OEM & Architectural Solution

You’re looking for custom metal forming services, and you come across roll forming – but there’s two kinds: OEM and arch …

Roll Forming Tooling Design: Build In-House or Outsource?

Which charges higher prices for metal fabrication -- a company that has in-house roll forming tooling design capabilitie …

Warehouse Storage Racks and Conveyors: Consider Roll Forming

Global shifts are sharply impacting the way companies in the United States do business. Carrying on the trend toward exp …