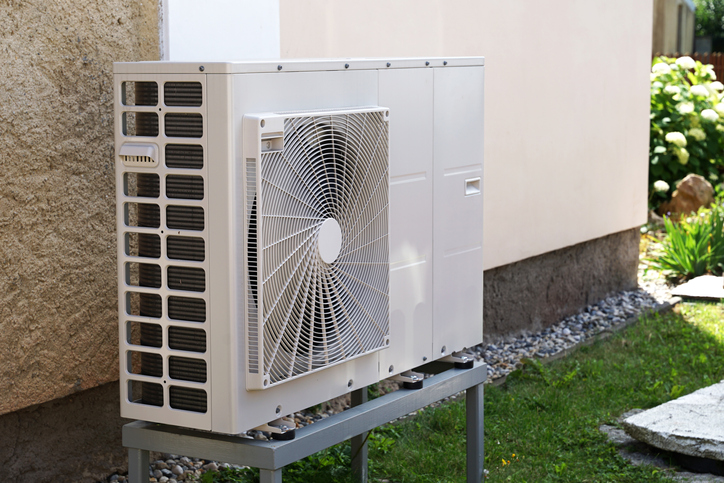

High-Quality Heat Pump Parts: Try Metal Roll Forming

The HVAC industry is witnessing a surge in heat pump popularity. Sales of heat pumps are outstripping gas furnaces for h …

4 Steps to Controlling Roll Forming Costs

Control your roll forming costs without sacrificing parts’ quality with these four steps to efficiency: Roll former spee …

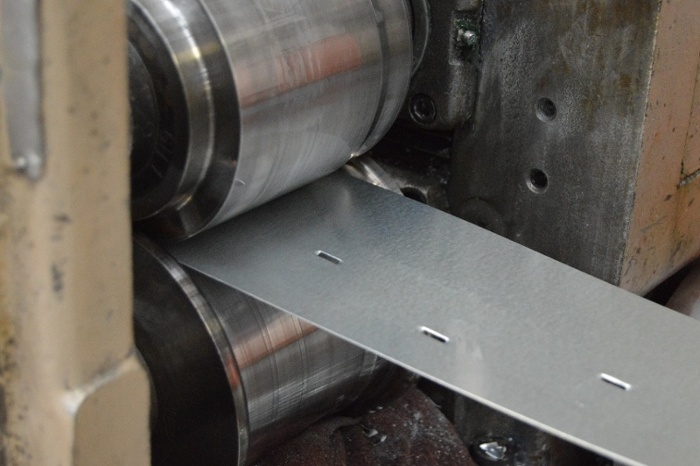

Sheet Metal Roll Forming: Assessing Cost, Ability, & Quality

Sheet metal roll forming is one of the most affordable metal fabrication processes. The ability to manufacture large qua …

A Roll Forming Design Guide for Enclosed Trailer Parts

In the competitive world of trucking, every pound counts. Creating commercial trailer parts requires balancing innovatio …

Harnessing Metal Roll Forming for Indoor Vertical Farming Systems

The landscape of agriculture is transforming, driven by a growing demand for sustainable, local, and year-round access t …

Shaping the Energy Infrastructure: How Roll Forming is Powering the Renewable Energy Boom

The renewable energy sector has seen unprecedented growth as the world pivots towards sustainable energy solutions. Amid …

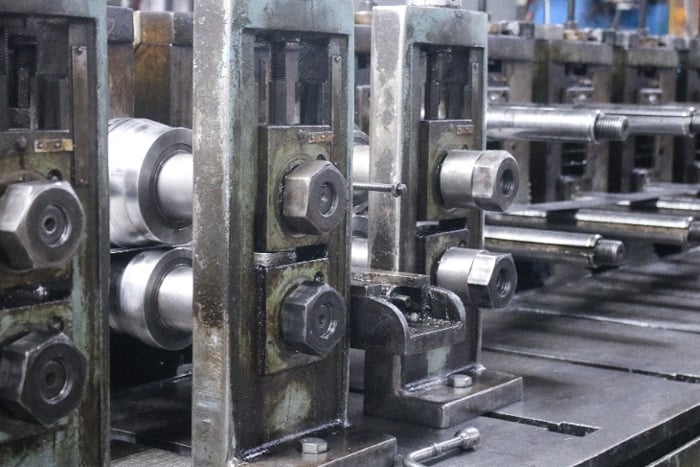

What Is Metal Roll Forming? | Metal Manufacturing Processes

“What is metal roll forming?” Even design engineers with 20+ years of experience still Google this question. Despite its …

Metal Forming Processes: Industries & Applications

Metal forming processes play a crucial role in powering our society, driving innovation across industries. They enable t …

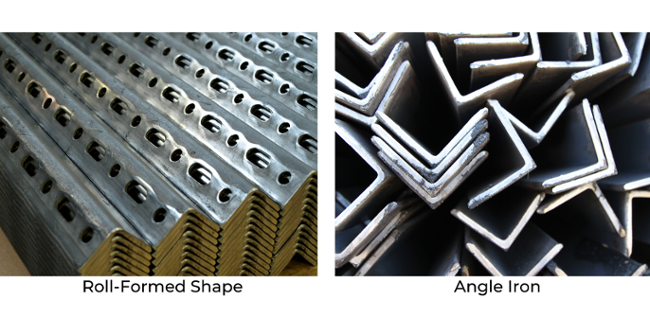

Need a metallic L-angle? Roll Forming vs. Angle Iron

You need long, slender, L-shaped metal components for your project. Several metal forming processes can achieve the desi …