HSLA Steel Won't Break Your Back (Or Bank)

While conventional steel is renowned for its strength, it often carries the burden of significant weight. This associati …

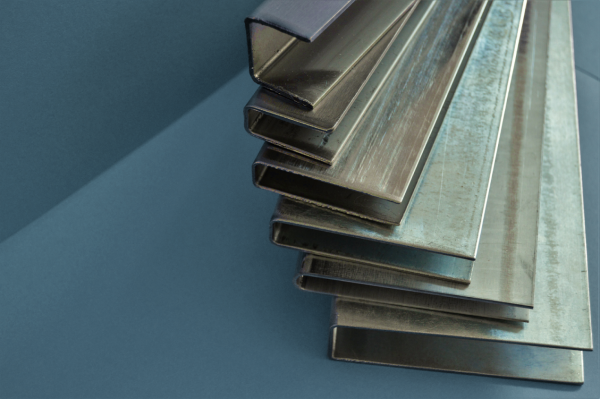

5 METAL ROLL FORMED PROFILES YOU CAN'T (OR SHOULDN'T) MAKE OTHER WAYS

Think of roll forming as the ability to make creations using an Etch-a-Sketch or drawn with your pen without lifting the …

Roll Forming Services: Your OEM & Architectural Solution

You’re looking for custom metal forming services, and you come across roll forming – but there’s two kinds: OEM and arch …

Roll Forming Tooling Design: Build In-House or Outsource?

Which charges higher prices for metal fabrication -- a company that has in-house roll forming tooling design capabilitie …

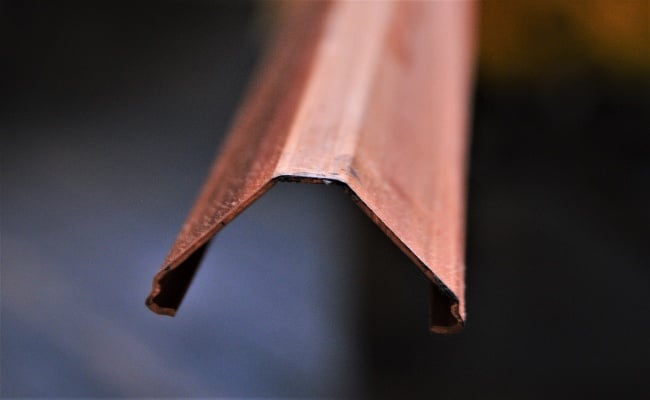

Green Metal?! Discovering the Patina Effect

Like with many other things in life, age is a big talking point in decorative metals. Is youthful glow better, or is the …

4 Elegant Mouldings and Finishing Ideas in Copper, Bronze & Brass

Finishing is the process of treating the exterior of a metal by applying a protective layer or unique aesthetic touch to …

Eco-friendly Interior Design Materials: Is Steel Sustainable?

Is steel a sustainable material? Incredibly so. It’s also available in multiple forms -- stainless, galvanized, carbon, …

A Vendor Can Take Your Architectural Metal Mouldings to Another Level

Most people aren’t lucky enough to run a business in or live in an older building classically adorned with metal mouldin …

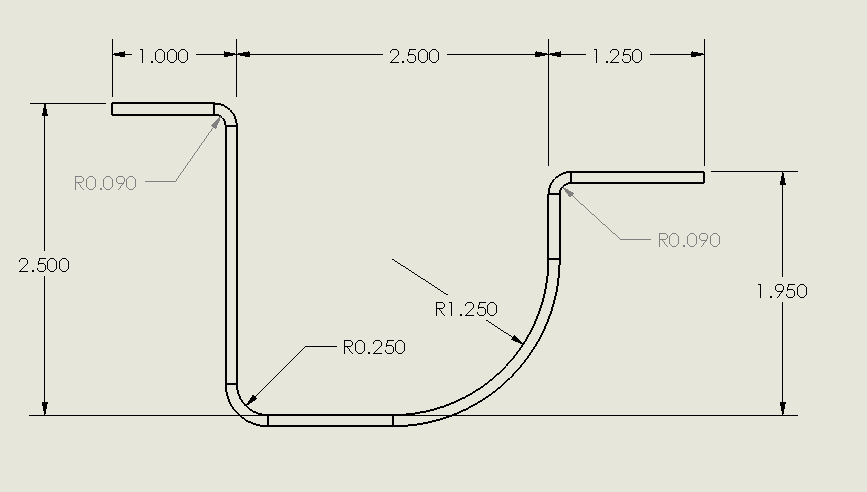

How U Channel Trim Moulding Completes Wire Mesh & Architectural Panels

A great roll formed steel U channel can do wonders for your project’s cost- and time effectiveness. That’s why we create …