How Vendor Managed Inventory Benefits Your Bottom Line

Maintaining an inventory of what a client needs for production is a delicate and complicated balance. As inventory ages, …

How Roll Forming Limits Your Total Manufacturing Cost of Ownership

When it comes to metal forming cost, if price is the battle, total manufacturing cost of ownership or -- TCO -- is the w …

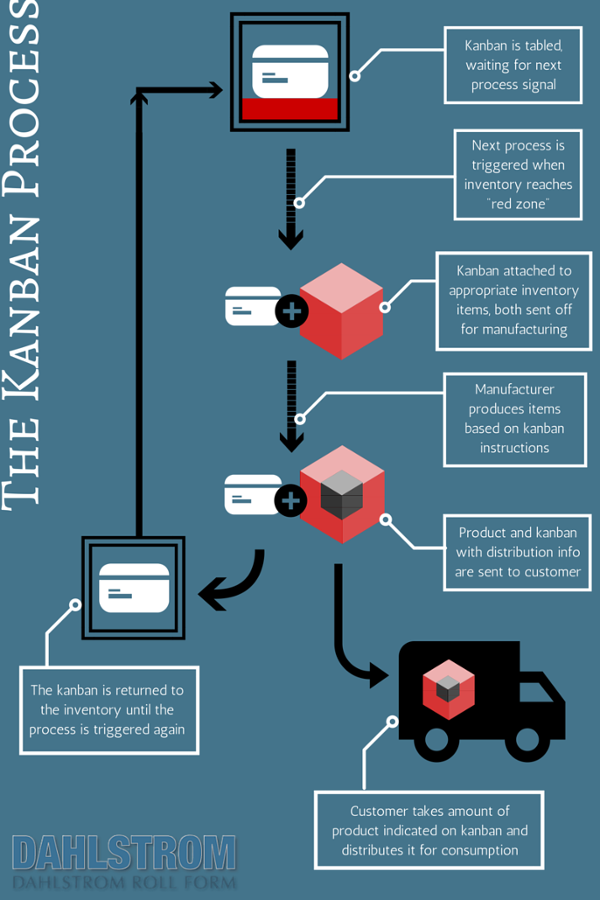

Keep Roll Forming Costs Under Control With Kanban Inventory Management

Keeping control of inventory requires intentionality. Insufficient inventory management leads to more waste, higher cost …

VIDEO: The Shortcut to Better Structural Steel Mechanical Properties

The strength of steel and its alloys has come a long way.

A Supplier Agreement With A Roll Forming Company Should Look Like This

The idea behind a supplier agreement -- whether with a roll forming company or another manufacturer -- is pretty simple. …

6 Ways to Get More Out of Your OEM Metal Roll Forming Process

Does your roll former bring you value beyond simply just doing roll forming? To be competitive, a manufacturer has to of …

Why Get Custom Roll Forming From a Single Source?

For manufacturers who require a continuous flow of custom roll forming, late shipments and stock outages can negatively …

Beyond Costs: Roll Forming Advantages & Value

You need a metal forming process that will produce a quality product at the right price, meet your inventory needs, and …

What Is a Roll Forming Machine? Roll Forming vs. In-House Forming

Sometimes it’s good to know when to ask for help. This is especially true when making decisions for a large business.

Can Copper Antimicrobial Products Make Hospitality Design Safer?

The coronavirus pandemic has forever changed the way many of us think about architectural design and materials.