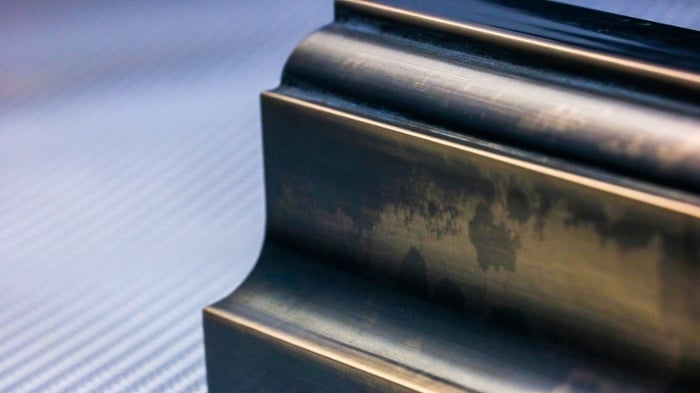

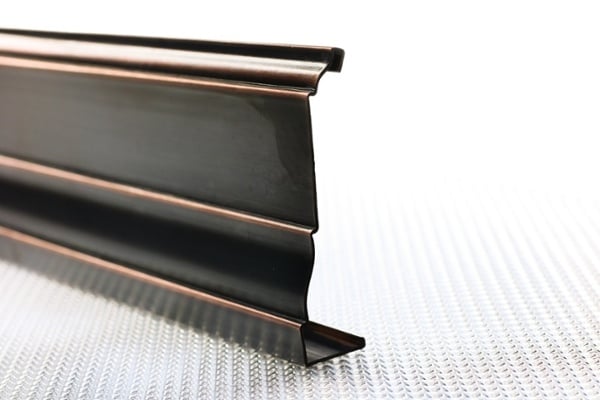

Metal Mouldings 101: The Dahlstrom Bedrock

At Dahlstrom, we fabricate only the highest quality metal mouldings to help you create a sleek, elegant atmosphere for a …

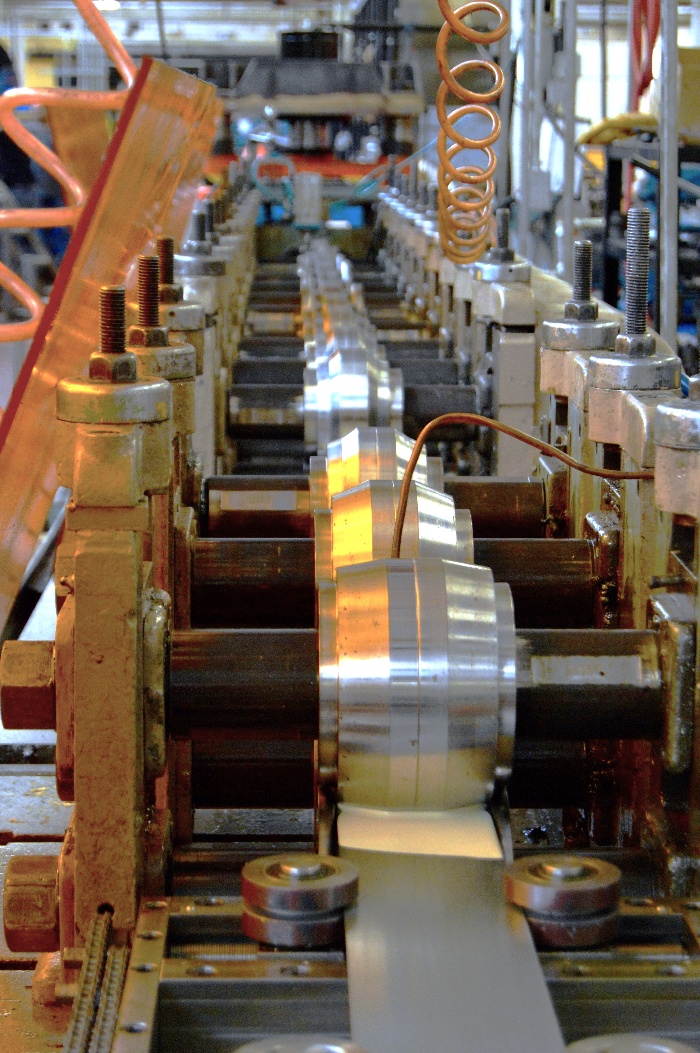

Ever Wonder How Dahlstrom Architectural Mouldings Are Made?

The Empire State Building is an architectural wonder. Delighted by its size and signature Art Deco style, architecture p …

Roll Forming Design Guide for Sheet Metal Components

People not familiar with roll forming usually need some education regarding the machines’ capabilities and limitations – …

6 Ways to Get More Out of Your OEM Metal Roll Forming Process

Does your roll former bring you value beyond simply just doing roll forming? To be competitive, a manufacturer has to of …

Are You Getting Roll Forming Services From An Agile Manufacturer?

What makes a link in your supply chain “agile?” To answer, look at your favorite examples of modern manufacturers and pr …

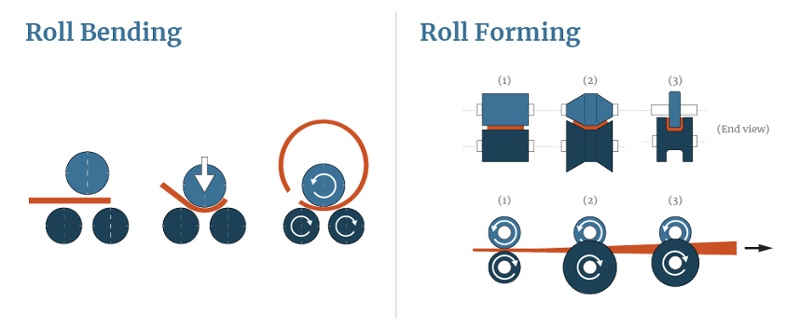

Do You Need a Roll Former or a Roll Bender?

We’re often asked if we can make metal cylinders or “rings.” And while these things are made with a rolling process, tha …

Decorative Metal Trim Mouldings vs. Wood Mouldings

Soon after their introduction in 1910, Dahlstrom’s metal mouldings were being used exclusively by some of the most famou …

MeshTrim: Custom Framing for Decorative Wire Mesh

As an architectural designer, the last thing you want is a creative barrier.

Why Get Custom Roll Forming From a Single Source?

For manufacturers who require a continuous flow of custom roll forming, late shipments and stock outages can negatively …

Reshoring Your Roll Forming To Create a More Efficient Supply Chain

You’ve seen the pictures of shipping barges idling off the coasts of the United States. You may have had delays in shipm …