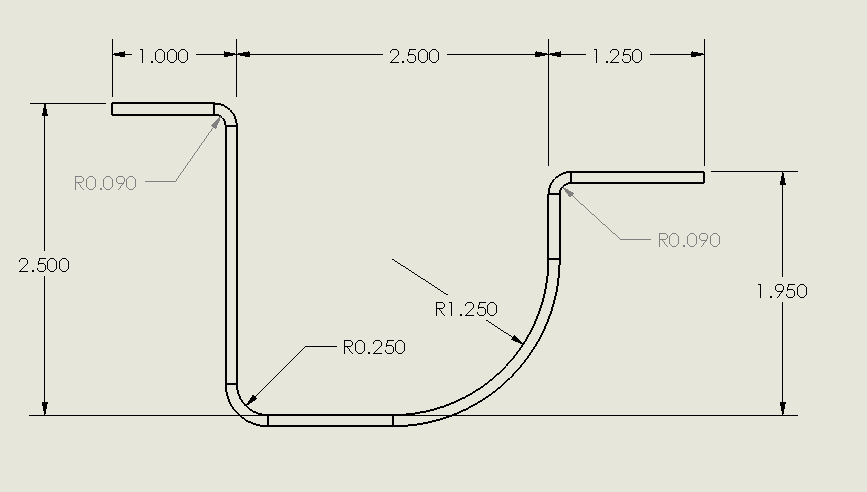

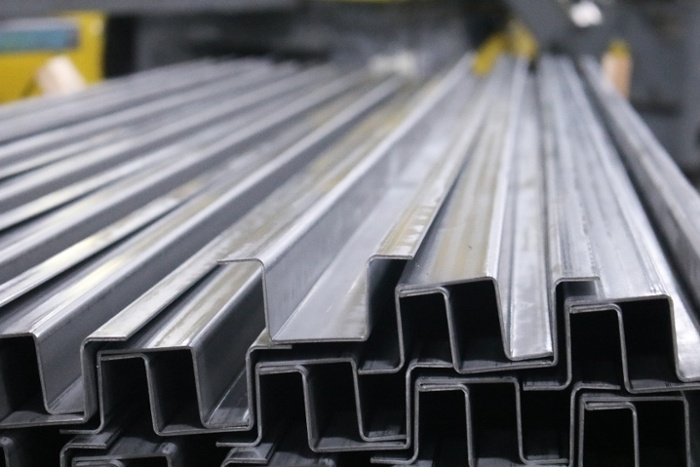

5 METAL ROLL FORMED PROFILES YOU CAN'T (OR SHOULDN'T) MAKE OTHER WAYS

Think of roll forming as the ability to make creations using an Etch-a-Sketch or drawn with your pen without lifting the …

Want to Lower Sheet Metal Forming Costs? 5 Ways Roll Forming Can Help

Roll forming is one of the most efficient and cost-effective methods of sheet metal forming. However, it isn’t free. So …

The Benefits of Securing a Roll Forming Second Source Supply

Do you remember the good old days, circa 2018, when your main concern in supply chain management was visibility and cons …

Power Distribution System Components: Roll Forming Benefits

The U.S. power distribution sector is under a storm cloud.

Industrial Paints & Coatings: Types of Metal Finishes

Metal finishes are a critical component of many industrial applications, serving to protect your industrial parts’ surfa …

Data Center Rack Design & Infrastructure: Is Roll Forming a Fit?

Data centers are the backbone of today’s digital world.

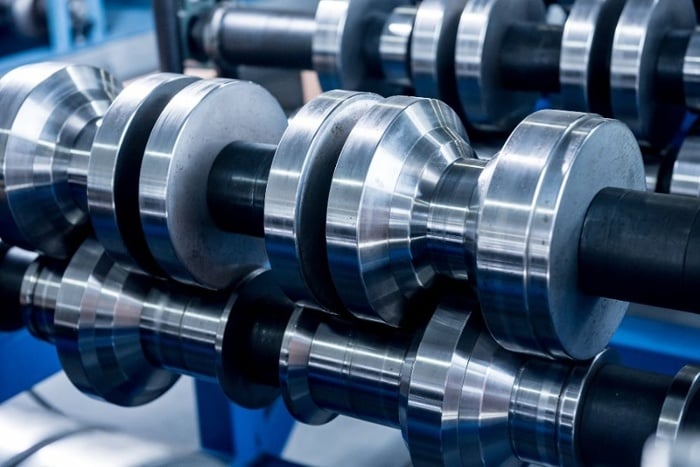

Custom Roll Forming Processes: Cold Roll Forming Steel

Metal fabrication can be complex, but there are certain methods that can be used to make it simpler and more efficient.

Career Advancement: See Yourself Growing at Dahlstrom

Are you always seeking to improve yourself and learn new things?