Cold Roll Forming Vs. Hot Rolled: Which is Right for Your Project?

The Cold, Hot Facts Between Cold Roll Forming and Hot Rolling When selecting roll forming for your projects, durability, …

HSLA Steel Won't Break Your Back (Or Bank)

While conventional steel is renowned for its strength, it often carries the burden of significant weight. This associati …

A Metal Roll Forming Partner Mustn't Be Big to Boost Your Business

Are you searching for a manufacturing partner capable of producing large quantities of products? Who is both efficient a …

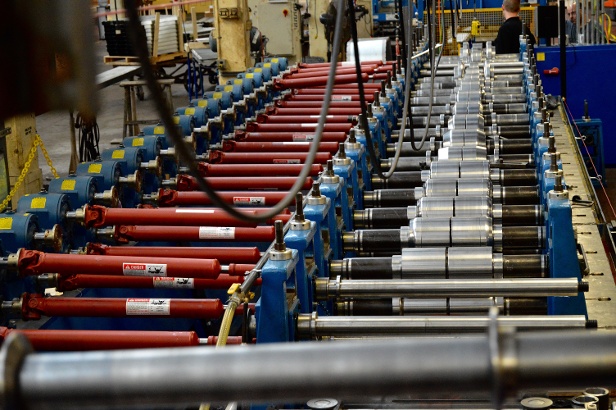

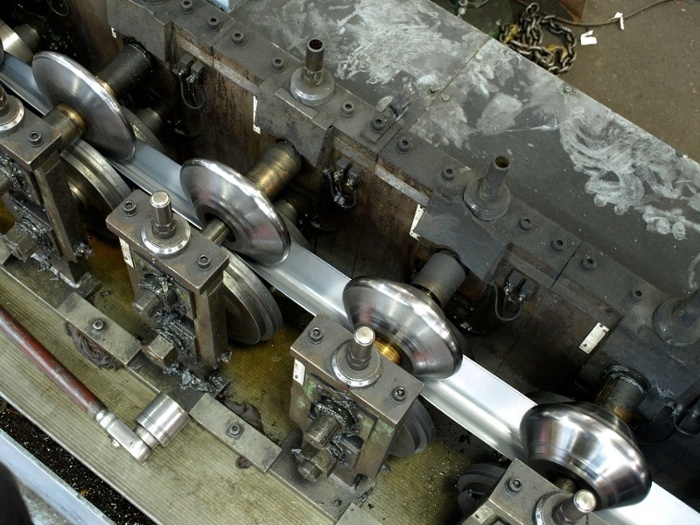

Understanding The Roll Form Tooling Process

As far as metal forming techniques go, roll forming has long been a standard for OEMs. You’re probably already familiar …

Outsourcing Roll Forming Tooling: Cost Savings Down the Line

Tooling costs in manufacturing are already a sore spot for many purchasers, but some think roll form tooling is cost-pro …

Roll Forming Commercial HVAC Material Selection Guide

Have you ever felt the comforting rush of cool air on a sweltering summer day or the warmth that chases away the winter …

Roll Forming Advantages: Efficiency & Cost-Savings

Since the turn of the 20th century -- or perhaps much earlier -- roll forming has been used to quickly and cost-effectiv …

The Hidden Expense: Roll Forming Raw Material Cost

OEM projects can be hectic. Your main concerns are likely lead time, reliability, quality, customer satisfaction, and co …

Choosing the Right Path: Roll Forming vs. Other Metal Parts Manufacturing Processes

As manufacturers, we all know that the magic behind a top-notch product lies in a solid manufacturing process, but with …

Commercial HVAC-R Parts: Is Roll Forming a Fit?

The commercial HVAC-R (heating, ventilation, cooling, and refrigeration) industry is rapidly growing. Experts predict th …