The Benefits of Using a Full-Service Roll Forming Company

Full-service roll forming companies should give you expert advice, help you design quality parts, and find ways to keep …

A Metal Roll Forming Partner Mustn't Be Big to Boost Your Business

Are you searching for a manufacturing partner capable of producing large quantities of products? Who is both efficient a …

Outsourcing Roll Forming Tooling: Cost Savings Down the Line

Tooling costs in manufacturing are already a sore spot for many purchasers, but some think roll form tooling is cost-pro …

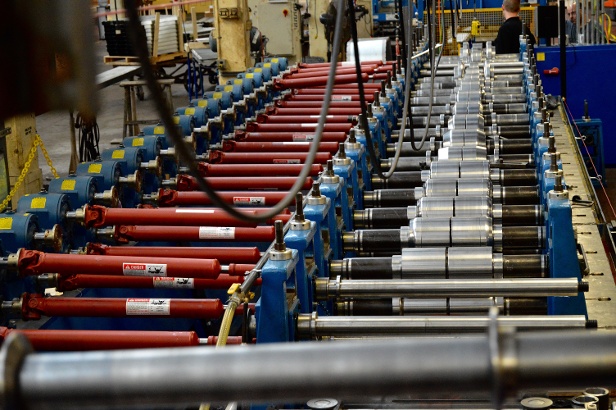

Roll Forming Advantages: Efficiency & Cost-Savings

Since the turn of the 20th century -- or perhaps much earlier -- roll forming has been used to quickly and cost-effectiv …

The Hidden Expense: Roll Forming Raw Material Cost

OEM projects can be hectic. Your main concerns are likely lead time, reliability, quality, customer satisfaction, and co …

4 Steps to Controlling Roll Forming Costs

Control your roll forming costs without sacrificing parts’ quality with these four steps to efficiency: Roll former spee …

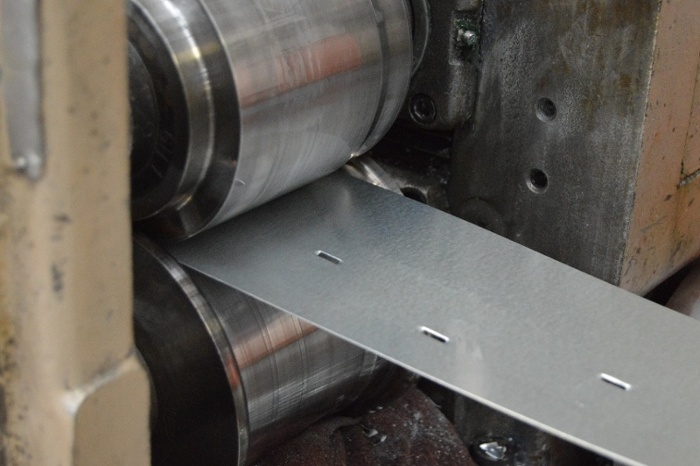

Sheet Metal Roll Forming: Assessing Cost, Ability, & Quality

Sheet metal roll forming is one of the most affordable metal fabrication processes. The ability to manufacture large qua …

6 Important Factors in Manufacturing a Solar Racking System

Solar energy is thriving in the United States, fueled by an impressive 24% average annual growth rate over the past deca …

Want to Lower Sheet Metal Forming Costs? 5 Ways Roll Forming Can Help

Roll forming is one of the most efficient and cost-effective methods of sheet metal forming. However, it isn’t free. So …

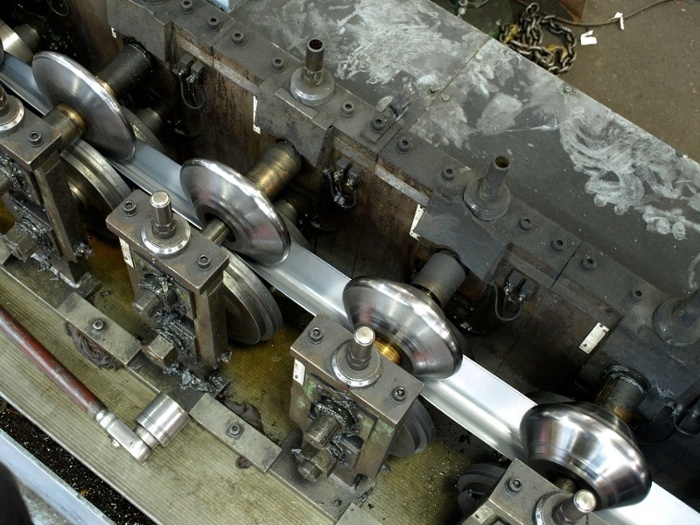

Roll Forming Tooling Design: Build In-House or Outsource?

Which charges higher prices for metal fabrication -- a company that has in-house roll forming tooling design capabilitie …