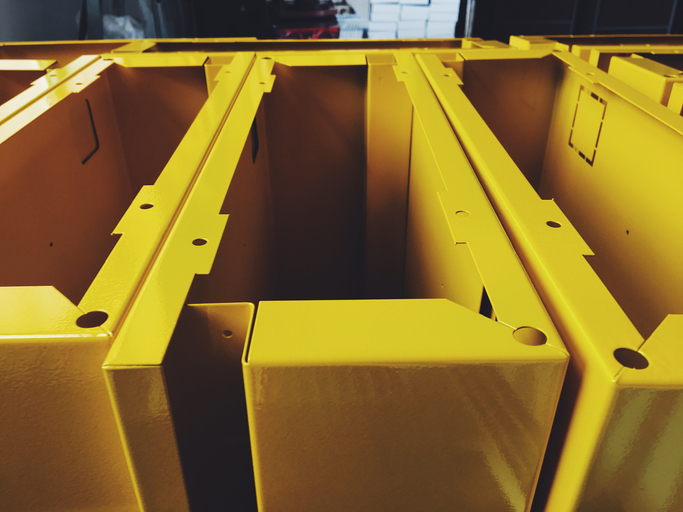

Goodbye Gray: Powder Coated Steel Roll Formed Parts

Most people wouldn’t name gray as their favorite color. In most instances, the hue carries with it a drab connotation.

Can You Powder Coat Aluminum? And Other Powder Coating FAQs

For many metal parts finishing projects, powder coating is a great option.

What Is Powder Coating & Why Do Metal Components Need It?

Are you looking for a thick, durable, environmentally compliant, affordable, efficient, and functional finish for your f …

High-Performance Roll Formed Steel Channels for EMI Shield Enclosures

Picture a modern data center: thousands of servers humming in perfect synchronization, processing terabytes of critical …

Slim‑Profile Battery Shielding Rails for UPS Rooms

Why Slim‑Profile Rails Belong in UPS Rooms UPS (Uninterrupted Power Supply) system battery rooms are dedicated, restrict …

IRA Strengthens Customer–Metal Roll Former Partnerships

Since its passage in 2022, the Inflation Reduction Act (IRA) has provided manufacturing industries with a strong push to …

The Benefits of Using a Full-Service Roll Forming Company

Full-service roll forming companies should give you expert advice, help you design quality parts, and find ways to keep …

Roll Forming Sheet Metal: Precision Roll Forming Machines & Dies

Ever wonder how the sleek, sturdy metal parts that power everything from cars to skyscrapers come to life? It all starts …

Sheet Metal Parts: What Can & Can't Be Roll Formed?

Navigating the world of sheet metal parts while sticking to a budget can feel like a puzzle. But here’s where roll formi …

Using Total Quality Management in Manufacturing for Long-Term Success

Today, customers expect high-quality products and services more than ever. But how can businesses ensure consistent qual …