Theory of Constraints: How to Shore Up Your Manufacturing Weaknesses

Every manufacturing setup has limits in achieving its goals. The Theory of Constraints (TOC) is a management methodology …

This High Run Speed Hydraulic Press Cuts Your Roll Forming Costs

Have an OEM project that demands precision punching on a tight turnaround? Need help controlling roll forming costs? Dah …

What Is a Roll Forming Machine? Roll Forming vs. In-House Forming

Sometimes it’s good to know when to ask for help. This is especially true when making decisions for a large business.

What’s ‘Just-in-Time’ Delivery Mean When Using Roll Forming Companies?

In the old days, it looked good when roll forming companies produced as much as possible. But that concept no longer fli …

201: The Hero You Deserve for Stainless Steel Outside Use

Have you ever heard about 201 stainless steel? It’s a surprisingly nice metal for outdoor projects that demand a blend o …

Galvannealed vs Galvanized Steel for Architectural Design

Galvannealed and galvanized steels start out similarly. They are both dipped into a hot zinc bath (approximately 850° F) …

Create a Streamlined Supply Chain for Wire Mesh Frame

MeshTrim is the most versatile woven wire mesh frame choice in the world. No, the universe.

Roll Formed parts: 5 Expert Tips for Designing the Worst Parts Ever

Who wants to make great roll formed parts? Not you, obviously.

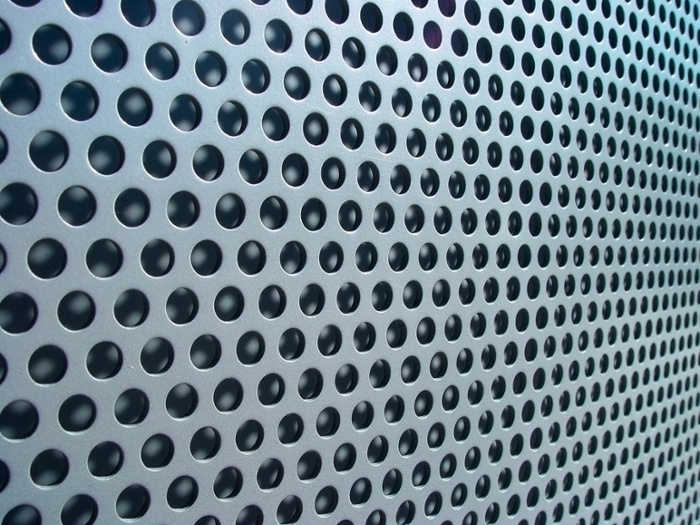

Roll Forming: A Versatile Sheet Metal Punching Partner

Roll formed components often require hole punching -- after all, that’s probably one reason why you chose roll forming t …

.jpg)