The 4 Most Common Myths of Roll Forming Metal

There are a lot of common misconceptions about roll forming metal. Four of the most common myths about the roll forming …

Communication Is Key To Supply Chain Risk Mitigation

When you think about supply chain risk mitigation, what are the first things that come to mind? For us, the usual suspec …

How Vendor Managed Inventory Benefits Your Bottom Line

Maintaining an inventory of what a client needs for production is a delicate and complicated balance. As inventory ages, …

Why ISO Manufacturing Standards Matter in Roll Forming

Many manufacturers requesting roll forming services ask first and foremost: Can you prove your competence?

JIT Delivery: 1 Step a Roll Forming Manufacturer Must Take

There’s nothing new or mysterious about “just-in-time” or JIT manufacturing. The idea has been around since the 1970s, a …

How Roll Forming Limits Your Total Manufacturing Cost of Ownership

When it comes to metal forming cost, if price is the battle, total manufacturing cost of ownership or -- TCO -- is the w …

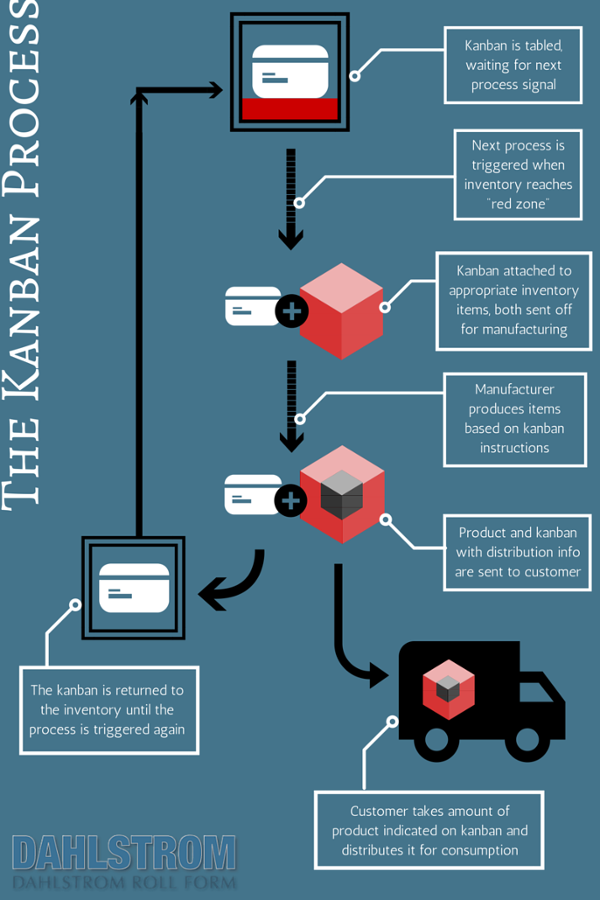

Keep Roll Forming Costs Under Control With Kanban Inventory Management

Keeping control of inventory requires intentionality. Insufficient inventory management leads to more waste, higher cost …

Dahlstrom: Your Custom Roll Forming Partner

Your business is in a niche market. Your suppliers should treat you accordingly.

VIDEO: The Shortcut to Better Structural Steel Mechanical Properties

The strength of steel and its alloys has come a long way.

A Supplier Agreement With A Roll Forming Company Should Look Like This

The idea behind a supplier agreement -- whether with a roll forming company or another manufacturer -- is pretty simple. …