Choosing the Right Path: Roll Forming vs. Other Metal Parts Manufacturing Processes

As manufacturers, we all know that the magic behind a top-notch product lies in a solid manufacturing process, but with so many metalworking options available, choosing the right one can feel overwhelming.

The truth is that there is no perfect method for every project. Each manufacturing method brings its own unique strengths and weaknesses to the table, and understanding the applications is key to supporting your operational production needs.

Here’s a look at the pros and cons of four main metal parts forming processes used today:

- Roll forming

- Press braking

- Stamping

- Extrusion

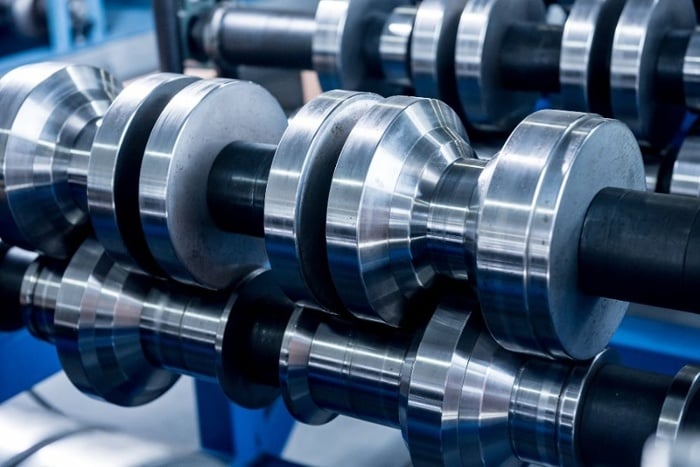

1. Roll Forming

Roll forming involves gradually bending flat sheet metal into a longitudinal, uniform profile by passing it through a series of mated tool dies.

THE ADVANTAGES

Roll-forming tooling costs may be higher than those of other forming services, but roll-forming allows for more in-line fabrication, medium to large runs, and higher-volume orders.

Due to the more gradual forming sequence, roll forming produces very tight tolerances and an attractive finish. The process allows you to add tooling to create any shape, no matter how complex.

Because the material is coiled and fed through, there are no length limits. Roll forming is more cost-effective at high volumes. It allows in-line fabrication (lower labor cost) and can form high-strength steels while accommodating spring back.

THE DISADVANTAGES

There are only a few distinct drawbacks to the roll-forming process:

- Small orders are more expensive when compared to other metal forming services, like press brake forming.

- Tooling can be expensive, though it can be offset in the long term thanks to labor cost savings on a per-piece basis.

- An experienced operator must set up the roll-forming line.

- Roll forming produces end flare due to linear stresses, an issue where one end of the part flares outward. You can speak with your manufacturer about how to control flare, as there are many ways to approach it based on part geometry.

Roll forming performs best for projects that require medium to high volumes, tight tolerances, and an attractive appearance. You can learn more about it via the button below:

2. Press Braking Services

A press brake bends metal (usually sheet metal) to a predetermined angle by pinching it between a punch and a die. Press braking is efficient and cost-effective compared to other metal forming options, but only when working with small volumes and shorter part lengths.

THE ADVANTAGES

A brake press is easier to set up than other metal parts manufacturing services (depending on the number of dies needed for the complete forming sequence). It usually saves you both time and overall cost.

Brake press tooling is also often less expensive than roll forming or stamping.

THE DISADVANTAGES

Larger orders can (and do) get expensive quickly because brake forming is labor-intensive. Brake presses also cannot handle longer parts due to their relatively small sizes and designs.

Press braking runs into a few challenges in its forming process as well:

- It’s difficult to provide value-added features like holes or punched shapes during the forming process. If your product requires different features or fabrications, press braking may only be the first step in making your part.

- Multiple close bends, angles, radii, and hems are challenging for press braking due to how the press forms the metal. The brake dies aren't made for complex forming.

- A brake press requires an operator (or two for longer parts), and brake press strokes are slow and sequential. So, despite the lower initial tooling costs, the time and labor costs will quickly increase the overall cost of large orders.

- Press braking is not a delicate process; the force of the die shaping the metal often leaves scratches and tool marks, though if aesthetics don’t matter for your application, then you won’t need to worry about this as much.

- Press braking is not as accurately repeatable as other forming styles, with some referring to it as an "art" rather than a science due to its inconsistency. Tolerances are not as tight as with other types of metal forming, and the final product largely depends on the accuracy of the steel blank and how the blank was created.

Press braking might be ideal for your metal parts manufacturing needs if they don't require tight tolerances. If you don't necessarily care about initial appearances and have small order volumes, this metal parts manufacturing process will be ideal for your project.

3. Metal Stamping Services

Stamping involves placing a flat sheet (or coil) of metal into a stamping press, where a tool and die apply pressure to form the metal into a new shape or cut out a piece of metal.

THE ADVANTAGES

Stamping has been the go-to process for many years due to its ease and affordability.

Stamping also offers:

- Short cycle times

- The ability to produce complex and fabricated parts

- No need for a skilled operator

THE DISADVANTAGES

Stamping cannot produce long parts as it fights springback and leaves tool marks and scratches on the products.

In addition, metal stamping equipment has difficulties:

- When multiple lengths are required for the same profile, and each size requires a different stamping die, driving up tooling costs.

- Forming long parts, however, hiring workers to connect two or more pieces can alleviate this problem.

- Changing stamping patterns. Stamping tools can’t make punching pattern changes.

- Low costs must be maintained in the long term since the tooling to form longer parts becomes much more expensive than shorter parts.

The cost of metal stamping is highly dependent on your specific project needs. Jobs with shorter parts, parts of the same size, and no need for initial aesthetics may benefit from stamping for your metal parts manufacturing needs.

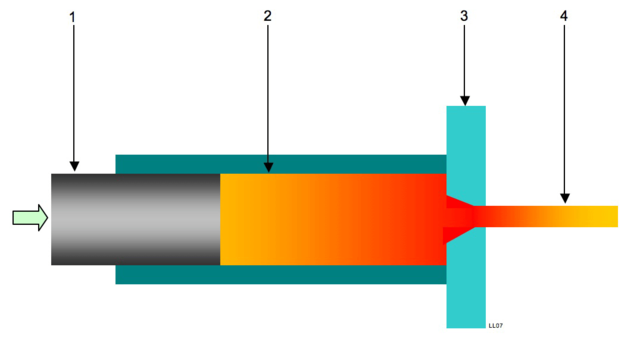

Extrusion Services

Extrusion is a metal forming process that forces metal through a die of the desired cross-section. It can be thought of as a Play-Doh squeezer or a pasta machine. The material is forced through a die while still soft to create the desired shape.

THE ADVANTAGES

The consistency of the die means an extruded part will have very tight tolerances.

Unlike press braking and stamping, extrusion allows for multiple cross-sections, wall thickness control, and incredibly low tooling costs.

THE DISADVANTAGES

There are four main disadvantages to extrusions:

- There are no value-added activities during the process. Extrusion does not allow for any fabrication while the metal is being formed, meaning that any added holes or features require secondary operations.

- It requires a secondary artificial aging process. Since the metal is pushed through the die while soft, it must travel through an aging oven once formed.

- Thin parts are a challenge. Although possible, extrusion isn’t the best way to form thin parts. As the parts are extruded, they are prone to tangling and deformation.

- It requires a tremendous investment in equipment and tooling. The chemical structure of steel means it's difficult to make it soft enough to force through the die. Because of this, steel extrusion is confined to only a handful of specialty companies globally, each requiring high order volumes to take on a project.

Extrusion is best for projects with thick-walled (0.060” +) aluminum, non-steel, and non-fabricated parts.

‘Must Ask’ Questions for Your Metal Parts ManufacturingCan I combine different metal-forming processes for my project? Yes, it's often possible to combine processes. For example, you could use roll forming to create a part's main shape and press braking to add secondary features. What types of materials can each of these processes work with? Roll forming, press braking, and stamping are commonly used with various metals, including steel, aluminum, and copper alloys. Extrusion is primarily used for aluminum but can also be used with other non-ferrous metals. What is the minimum order quantity for roll forming? There's no strict minimum, but roll forming is generally more cost-effective for medium to high volumes due to the initial tooling investment. |

Roll Forming vs. Other Methods: Making the Right Choice for Metal Parts

-

We can't stress enough that each metal production method has distinct advantages and disadvantages, and the nature and goals of your project will heavily influence your choice:

- Roll forming: designed for medium to high volumes, tight tolerances, and good looks.

- Press braking: specifically designed for small orders that don’t require tight tolerances or a pleasing aesthetic.

- Stamping: this process is specific to when your part is short, you have multiple parts with similar sizes, and looks don’t matter.

- Extrusion: is a niche solution for aluminum parts with thick walls that need tight tolerances or multiple cross-sections.

Want to Know More About Roll Forming?

When it comes to metal parts manufacturing, our expertise lies in roll forming. The free e-book below is a great initial tool for understanding how to make a more manufacturable and successful roll-formed part:

(Editor's Note: This article was originally published in January 2016 and was recently updated.)

You May Also Like

These Related Stories

The 4 Most Common Myths of Roll Forming Metal

Custom Roll Forming Processes: Cold Roll Forming Steel